3

SAFETY

SAFETY INFORMATION

(READ THOROUGHLY)

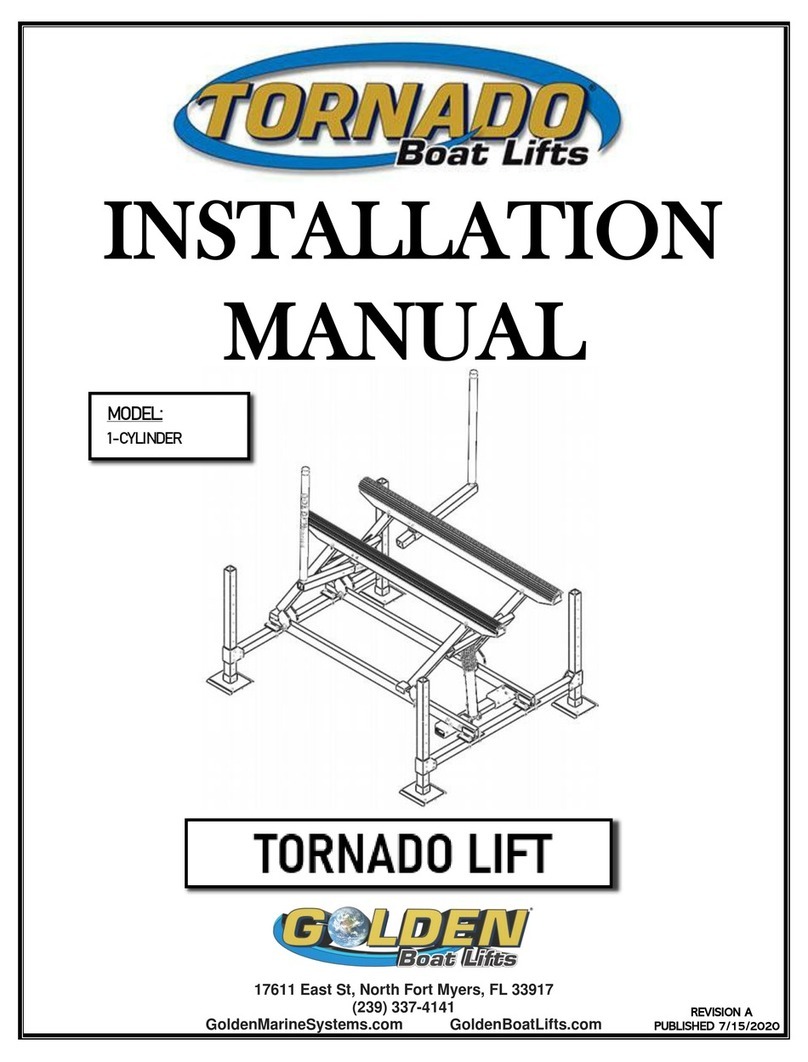

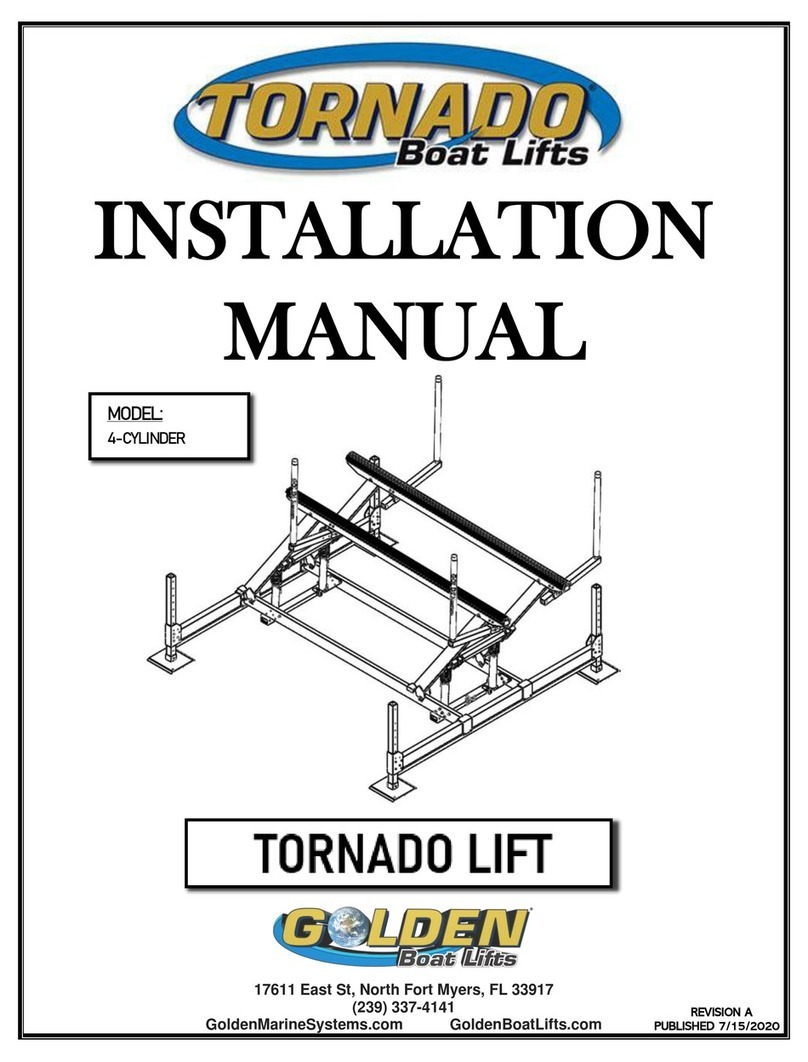

The TORNADO BOAT LIFT was designed, tested and certified to

be installed in the recommended area approved by certified

and approved personnel under the specific installation and

operation guidelines laid out in the installation and operation

manuals issued by GOLDEN BOAT LIFTS.

Note: Any installation or operation methods outside the

guidelines described within the manual(s) mentioned above

will void the product warranty.

Note: Only a trained and certified service provider should

install the Tornado boat Lift.

Note: Before beginning installation of the Tornado Boat Lift,

please ensure that the area selected for installation meets all

local and state guidelines and regulations.

Note: To avoid damage to the Tornado Boat Lift and/or personal

injury/death, carefully follow each step outlined in the

manual(s).

Note: Before beginning installation of the Tornado boat Lift,

clear adequate space around the installation site so that all

parts, hardware, and tools can be laid out in a safe and

organized fashion.

When completing the steps outlined in this Installation Manual,

please ensure that only proper handling and lifting techniques

are used to transport parts to desired locations. In some

circumstances, machinery may be required to move individual

parts.

The Tornado Boat Lift comes with a 12V DC Double-Acting

Hydraulic Power Unit (SPX Stone Hydraulic Power unit) which

provides the power for operation of the Tornado Boat Lift.

Note: After installation of the Tornado Boat Lift, please

reference the HYDRAULIC POWER PACK INSTALLATION

MANUAL provided to continue installation of the power supply

for the Tornado Boat Lift. Failure to reference and follow these

instructions before attempting to operate the Tornado Boat Lift

may cause damage to the lift and/or personal injury/death.

After completing the steps outline in the TORNADO

INSTALLATION MANUAL and the HYDRAULIC POWER PACK

INSTALLATION MANUAL, the Tornado Boat Lift should be ready

to operate.

Note: Before operation, it is important to verify that every step

outlined in the TORNADO INSTALLATION MANUAL and the

HYDRAULIC POWER PACK INSTALLATION MANUAL has been

correctly completed.

To operate the Tornado Boat Lift, please reference the

TORNADO BOAT LIFT OPERATING MANUAL.

Note: Never Exceed the maximum capacity of the lift.

Note: Never go under the lift or boat, especially when the lift

is in the raised position. Never operate a lift while on the lift

or inside the boat.

Note: It is recommended that the Tornado Lift be raised to the

upward position after removing the boat, indicating a hidden

underwater obstruction for others.