GL-9 Floor Plate Lift IN50018 Rev. B 05/30/2008

2

TABLE OF CONTENTS

• IMPORTANT INFORMATION ................................................................... 2

• GENERAL LIFT INFORMATION / FEATURES......................................... 3

• LIFT SPECIFICATIONS FOR GOLF LIFT ................................................ 3

• LIFT SPECIFICATIONS WITH ARM KIT .................................................. 5

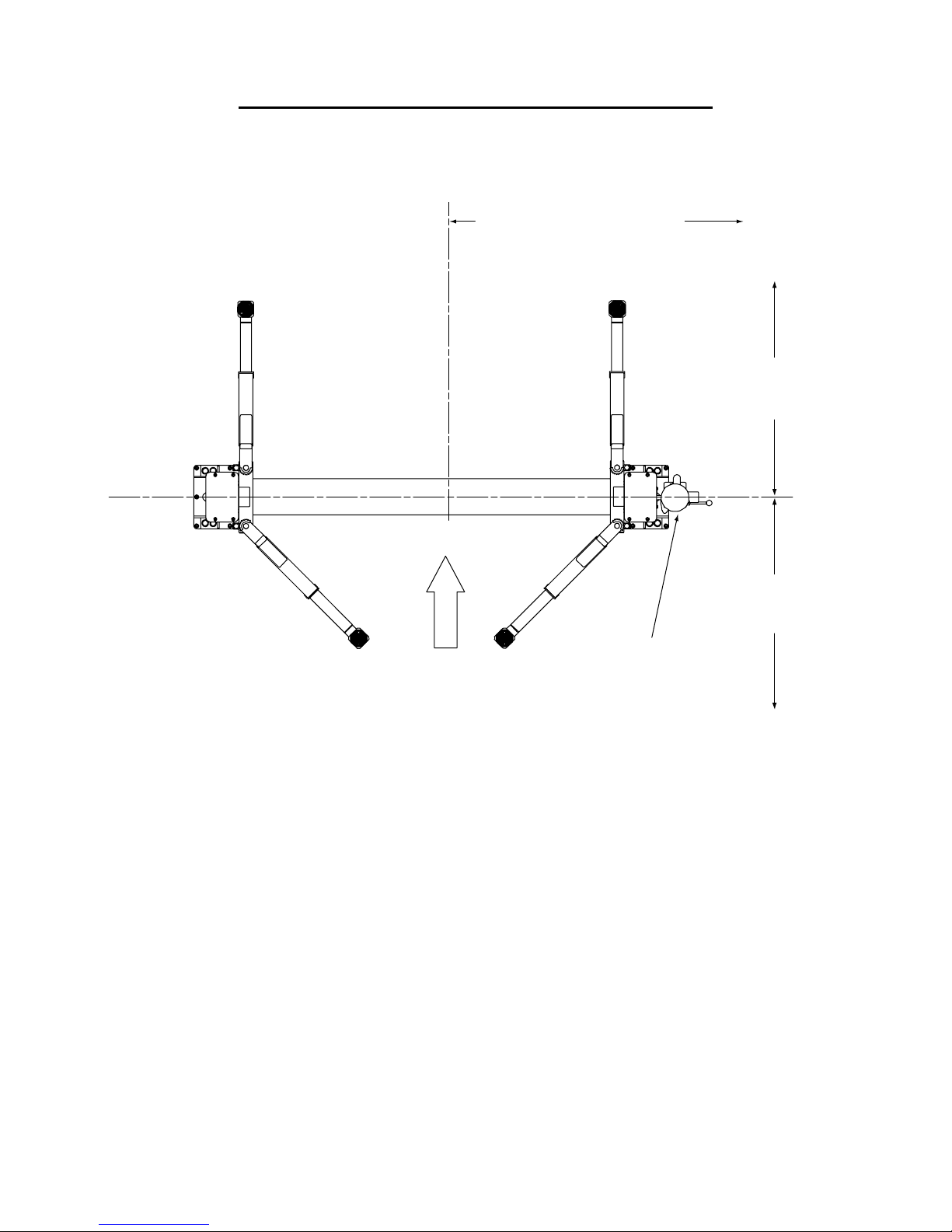

• LIFT AREA LAYOUT INFORMATION ...................................................... 6

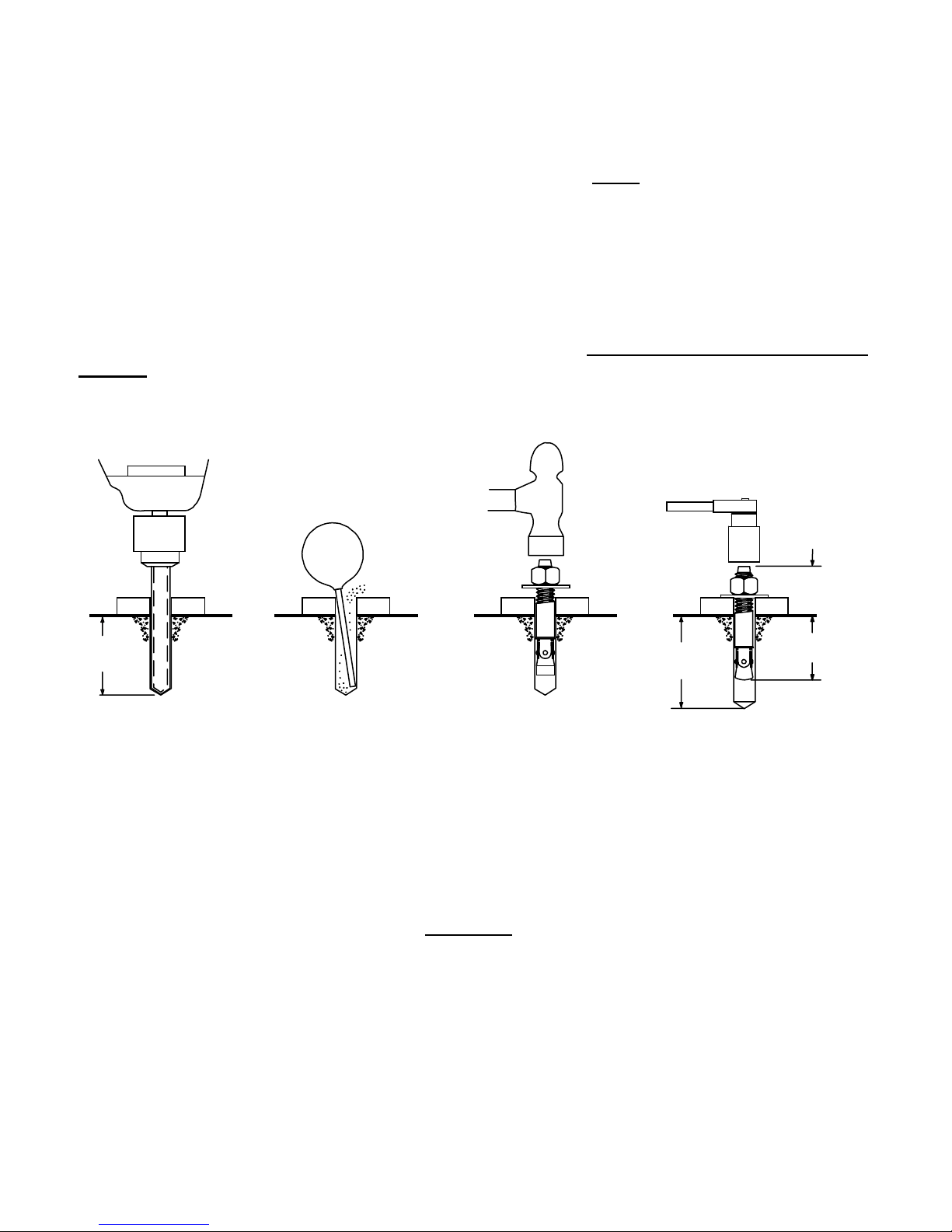

• FOUNDATION and ANCHORING REQUIREMENTS ............................... 7

• TOOLS and EQUIPMENT REQUIRED for INSTALL................................ 8

• INSTALLATION PROCEDURE................................................................. 9

• OWNER / EMPLOYER RESPONSIBILITIES ............................................ 14

• LIFT LOCKOUT/TAGOUT ........................................................................ 15

• SAFETY PROCEDURES .......................................................................... 16

• LIFT OPERATION..................................................................................... 18

• PREVENTIVE MAINTENANCE SCHEDULE ............................................ 20

• TROUBLESHOOTING .............................................................................. 22

• ILLUSTRATED PARTS BREAKDOWN.................................................... 24

• PARTS LIST.............................................................................................. 28

• WARRANTY POLICY ............................................................................... 31

IMPORTANT INFORMATION

Two Post Lifts

1. Any freight damage must be noted on the freight bill before signing and reported to the freight carrier

with a freight claim established. Identify the components and check for shortages. If shortages are

discovered, please contact the Distributor / Sales Rep. in your area for service.

2. Consult building owner and / or architect’s plans when applicable to establish the best lift location. The

lift should be located on a relatively level floor with 4 in. minimum thickness, 3000-psi concrete slab

that has been properly cured. There can be no cracks in the slab within 36 in. of the base plate

location, and no seams in the foundation within 6 in. of its location! Remember: any structure

is only as strong as the foundation on which it is located!

IMPORTANT! Make sure you have extra help or heavy duty lifting equipment when

unloading and assembling the lift.

3. Please read the safety procedures and operating instructions in this manual before operating lift. Keep

this manual near lift at all times. Make sure all operators read this manual.

4. The lift should be located on a relatively level floor of less than 3 degrees slope. If slope is

questionable, consider a survey of the site and/or the possibility of pouring a new level concrete slab.

5. Make sure you have enough area and ceiling height to install lift. (See Lift Specifications)

6. Never raise a car until you have double checked all bolts, nuts and hose fittings.

7. Always lower the lift onto the locks before going under the vehicle. Never allow anyone to go under

the lift when raising or lowering.

This is a vehicle lift installation/operation manual and no attempt is made or implied herein to

instruct the user in lifting methods particular to an individual application. Rather, the contents of

this manual are intended as a basis for operation and maintenance of the unit as it stands alone

or as it is intended and anticipated to be used in conjunction with other equipment.

Proper application of the equipment described herein is limited to the parameters detailed in the

specifications and the uses set forth in the descriptive passages. Any other proposed

application of this equipment should be documented and submitted in writing to the factory for

examination. The user assumes full responsibility for any equipment damage, personal injury, or

alteration of the equipment described in this manual or any subsequent damages.