Documentation HG G-73650ZD | English, Revision 05 | Date: 09.03.2017 | www.goetting-agv.com

2Table of Contents HG G-73650ZD

2.6.5.3 Automatic Mode ........................................................................................................................ 33

2.6.5.4 Remote Control Mode.............................................................................................................. 33

2.6.5.5 Vector Steering Mode .............................................................................................................. 34

2.7 Communication with the Vehicle Control (e.g. PLC) ............................................ 34

3 Hardware.............................................................................................. 36

3.1 Mounting............................................................................................................................ 37

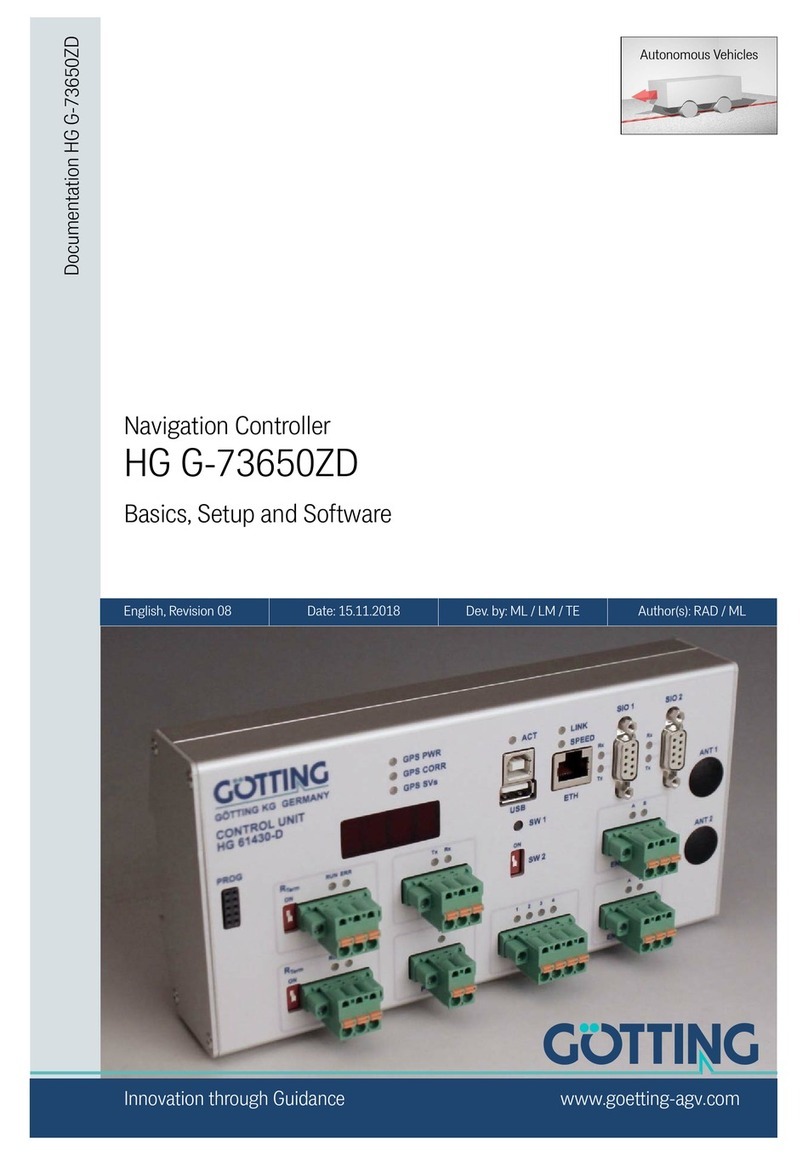

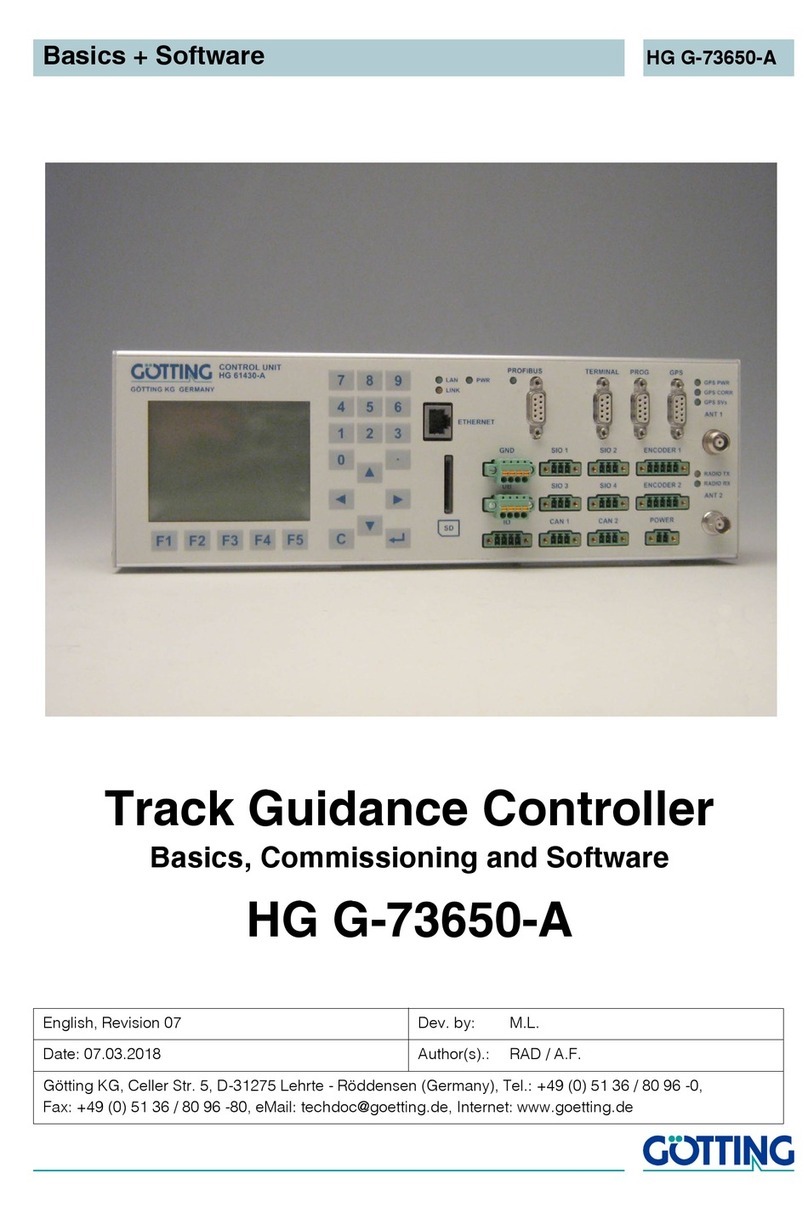

3.2 Front Panel ........................................................................................................................ 37

3.3 Control Elements on Front Panel ............................................................................... 37

3.4 Display Elements on Front Panel ............................................................................... 38

3.5 Connectors ........................................................................................................................ 38

3.5.1 ETH .................................................................................................................................................... 38

3.5.2 USB.................................................................................................................................................... 39

3.5.3 SIO 1 (GPS Receiver) ................................................................................................................... 39

3.5.4 SIO 2 ................................................................................................................................................. 39

3.5.5 CAN 1................................................................................................................................................ 40

3.5.6 CAN 2................................................................................................................................................ 40

3.5.7 SIO 3 ................................................................................................................................................. 40

3.5.8 POWER............................................................................................................................................. 41

3.5.9 IO........................................................................................................................................................ 41

3.5.10 ENCODER 1 / ENCODER 2......................................................................................................... 41

3.5.11 PROG ................................................................................................................................................ 42

3.5.12 ANT1 / ANT2 .................................................................................................................................. 42

3.6 Extension module Feldbus ........................................................................................... 42

4 Software............................................................................................... 43

4.1 Main menu......................................................................................................................... 44

4.2 Status menu...................................................................................................................... 45

4.2.1 Navigation menu ........................................................................................................................... 45

4.2.1.1 Status ............................................................................................................................................ 45

4.2.1.2 Deviation ...................................................................................................................................... 46

4.2.1.3 Seg. Table .................................................................................................................................... 46

4.2.1.4 Segment....................................................................................................................................... 46

4.2.1.5 PLC ................................................................................................................................................ 47

4.2.2 Transponder menu ....................................................................................................................... 48

4.2.2.1 Antenna ........................................................................................................................................ 48

4.2.2.2 Result ............................................................................................................................................ 49

4.2.2.3 Odometry ..................................................................................................................................... 49

4.2.3 GPS.................................................................................................................................................... 50

4.2.3.1 GPS ................................................................................................................................................ 50

4.2.3.2 ONS ............................................................................................................................................... 51

4.2.3.3 Controller Deviation.................................................................................................................. 51

4.2.3.4 Controller Correction................................................................................................................ 51

4.2.3.5 Status ............................................................................................................................................ 52

4.2.4 GPS Receiver.................................................................................................................................. 53

4.2.4.1 UTC ................................................................................................................................................ 53

4.2.4.2 Status ............................................................................................................................................ 53

4.2.4.3 Position......................................................................................................................................... 53

4.2.4.4 Diff. Data Age ............................................................................................................................. 53

4.2.4.5 Satellites ...................................................................................................................................... 53

4.2.4.6 Accuracy ...................................................................................................................................... 53

4.2.4.7 Base Vector ................................................................................................................................. 54

4.2.4.8 Heading ........................................................................................................................................ 54

4.2.5 Error .................................................................................................................................................. 55