INTRODUCTION

Section 1 - Page 3

STEP 2 – TERMINOLOGY

3D Printing All the plastic components in this kit are 3D printed using the latest equipment

and high quality, high-cost materials.

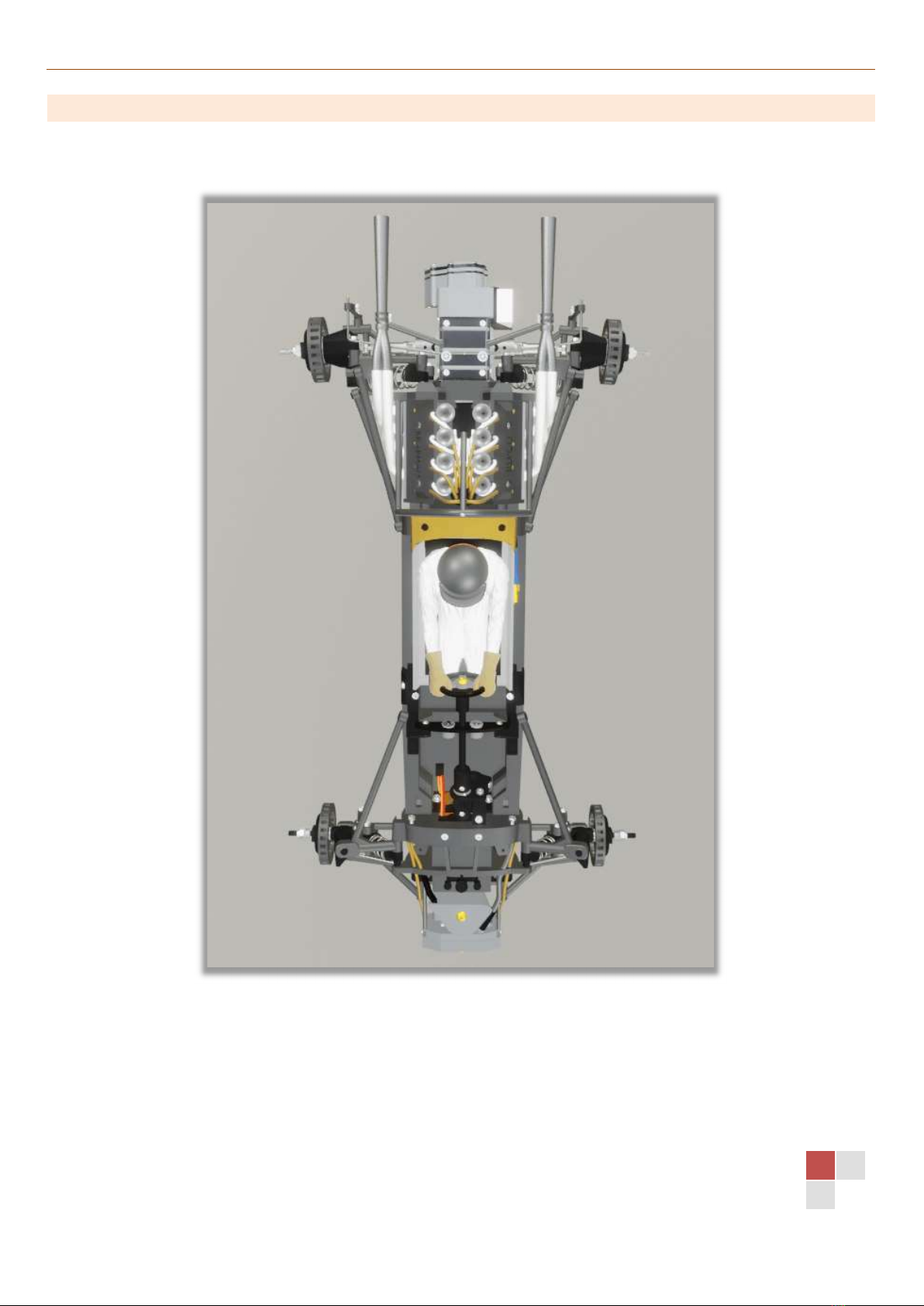

Nylon G Nylon is a very impact resistant plastic. We use MatterHackers NylonG which is

glass fibre impregnated nylon and is used for most of the main chassis,

bulkheads, engine bay, gearbox casing and suspension components.

PC Blend Is a blended variant of polycarbonate from Prusa and is extremely strong and

impact resistant. It’s used in the wheels, shocks, uprights, steering, gears, axles,

trumpets and mirrors.

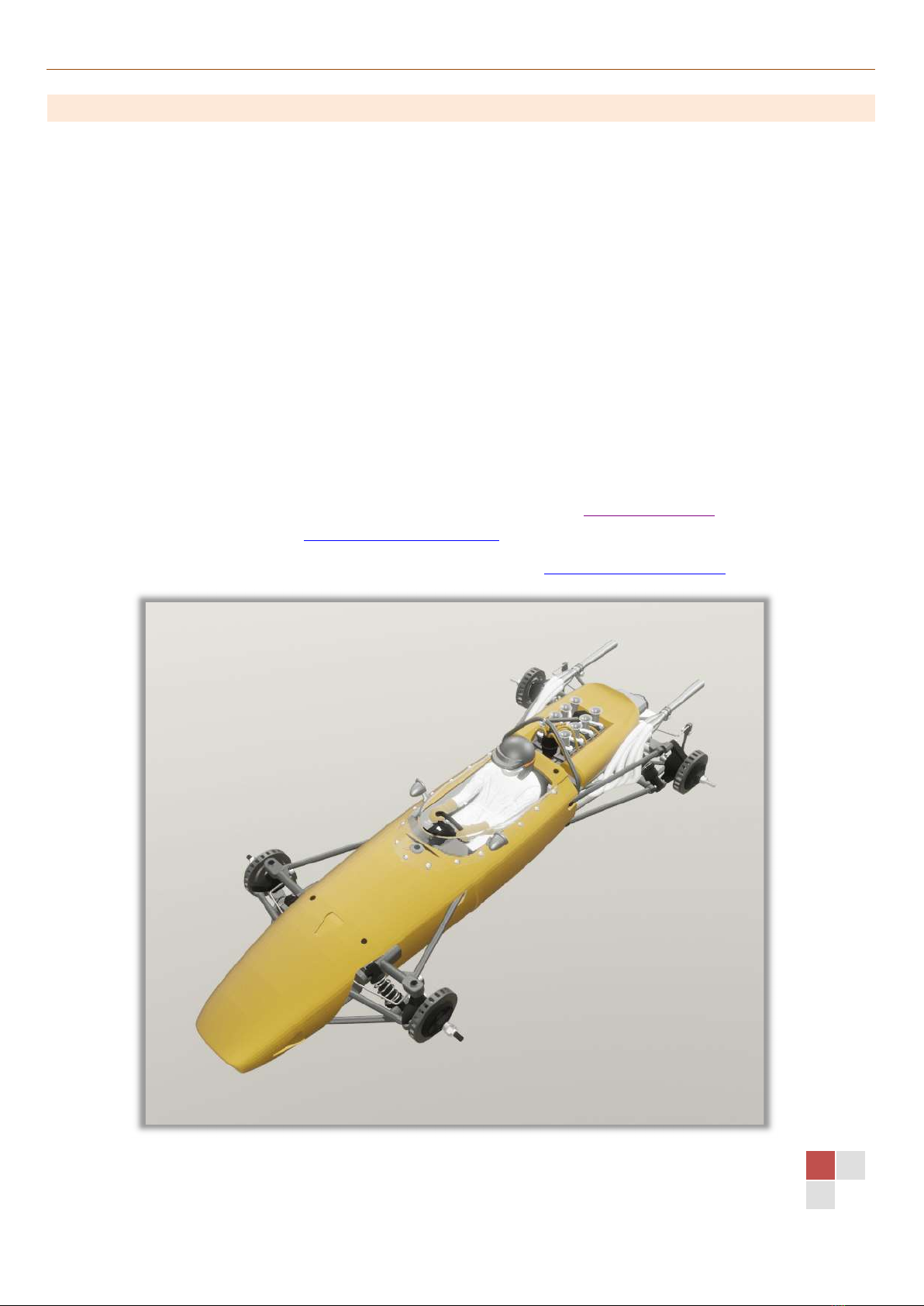

TPU Is an amazing flexible polymer we have used for the body shell and the ‘active’

driver figure! This material is super tough and capable of absorbing any

impacts. The kit comes with gold colour body parts; however, we also offer

these parts as customisable/options printed in a range of available colours. The

texture and finish perfectly captures the essence of the grand prix cars of the

1960’s era. You can also paint them with any flexible paint, such as

polycarbonate paint to achieve your favourite driver/livery!

PETG/Carbon Is a strong and hard polymer we have used for many of the cosmetic parts.

Brim For some of the printed parts a thin extra material layer is used during printing

to ensure the part does not prematurely detach from the print bed, this is called

a ‘brim’. Similar to injection moulded parts removed from the sprue, you will

need to remove the brim material and clean up the edges with a scalpel and/or

sand paper.

Hairs/blobs During the printing process sometimes very fine ‘hairs’ or small ‘blobs’ of plastic

remain on the part. We remove most of these during post processing the

components, but you can also clean up also using a scalpel and/or sand paper.

M1.6, M2, M2.5, M3 These four sizes of bolts/washers/nuts are used in this kit. Bolts all have Allen

socket heads.

M#cs The ‘cs’ part refers to counter sunk head.

M#button The ‘button’ part refers to button head.

M# x10mm Measurement in millimetres indicates the length of the screw thread. For

socket/button head this excludes the head, for counter sunk includes the head.

M# nylock nut The nylock nuts have the nylon insert part of the thread to resist coming loose.