Table of Contents...................................................................................................................................................................................................... ii

Parts Lists

Parts List Sure Stitch ...................................................................................................................iii

Carriages.................................................................................................................................... v

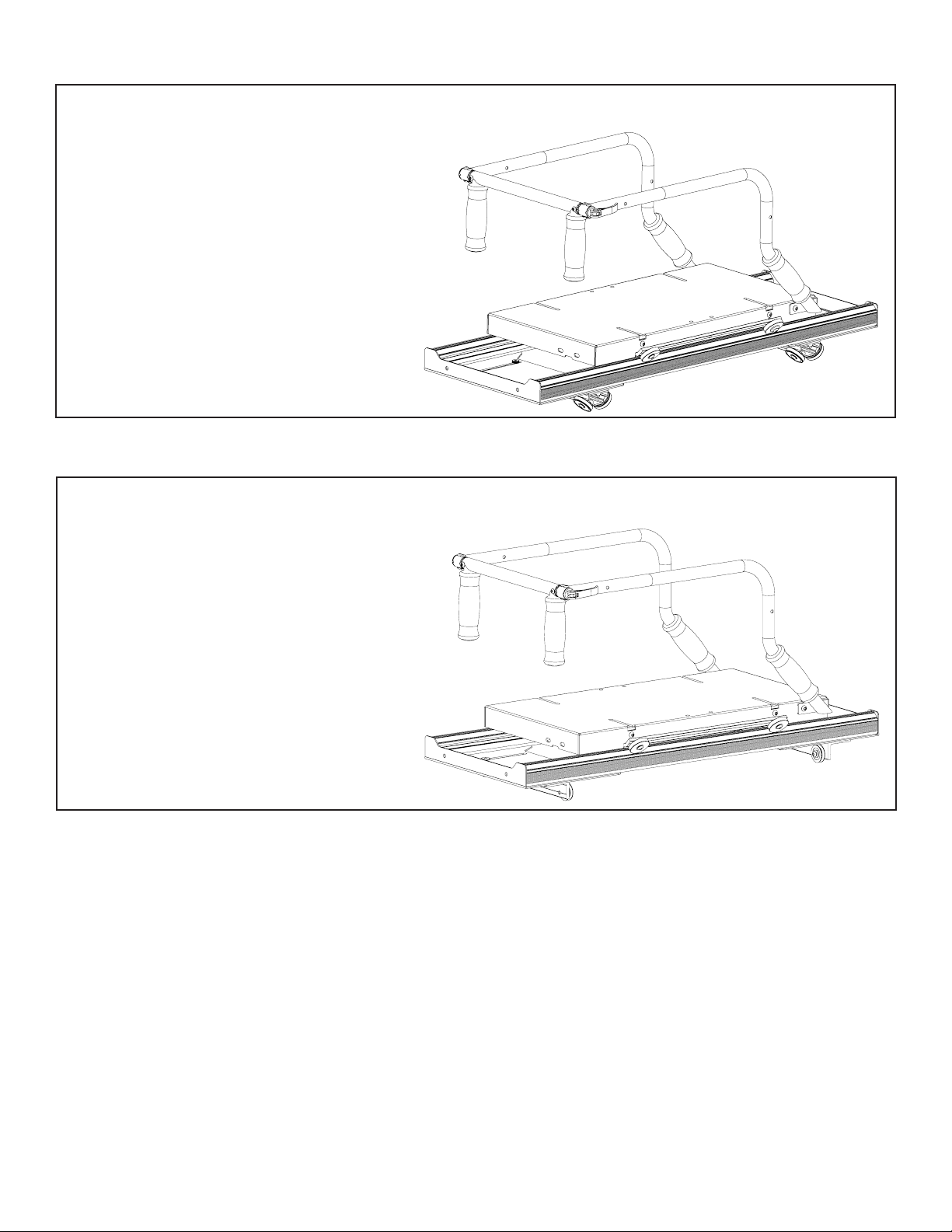

G-Series Carriage

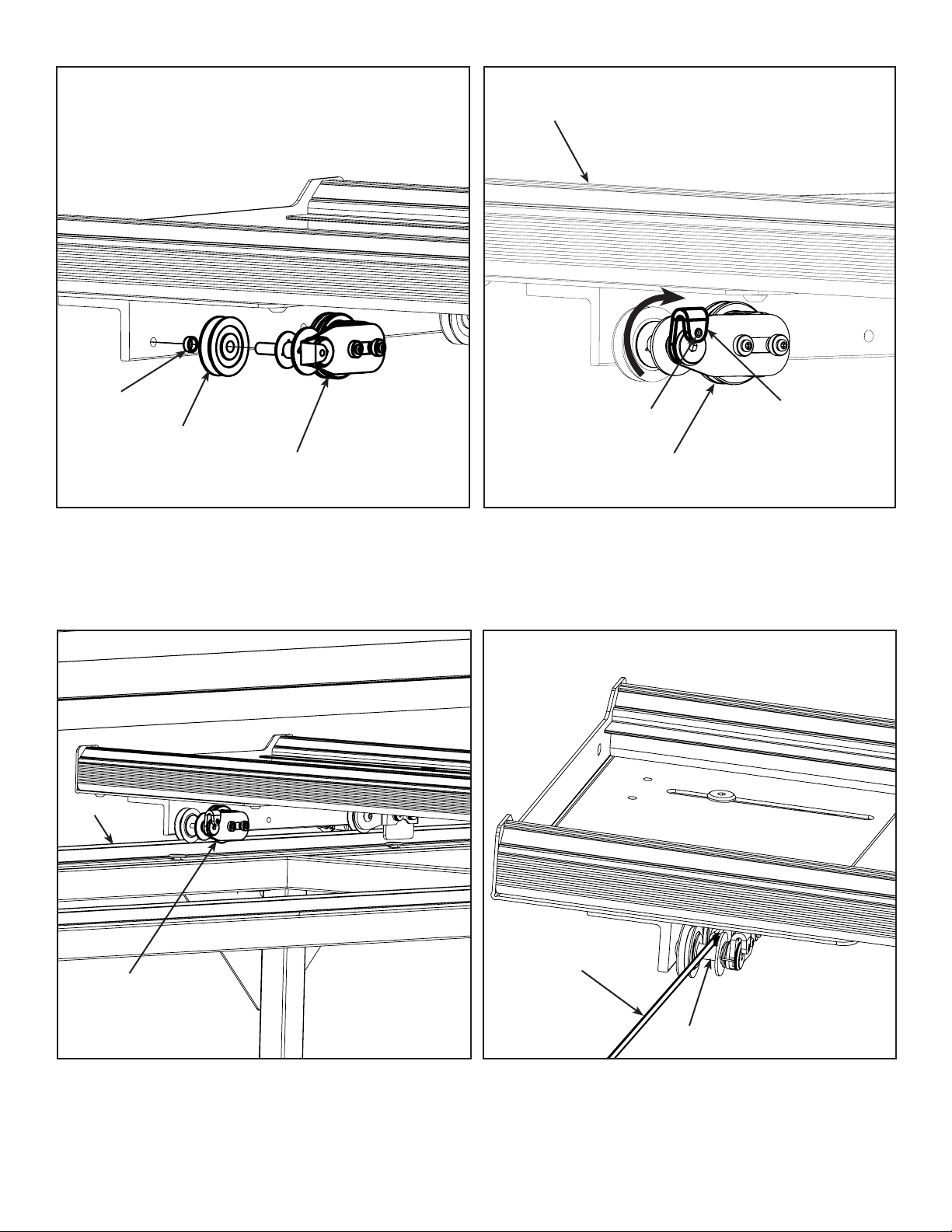

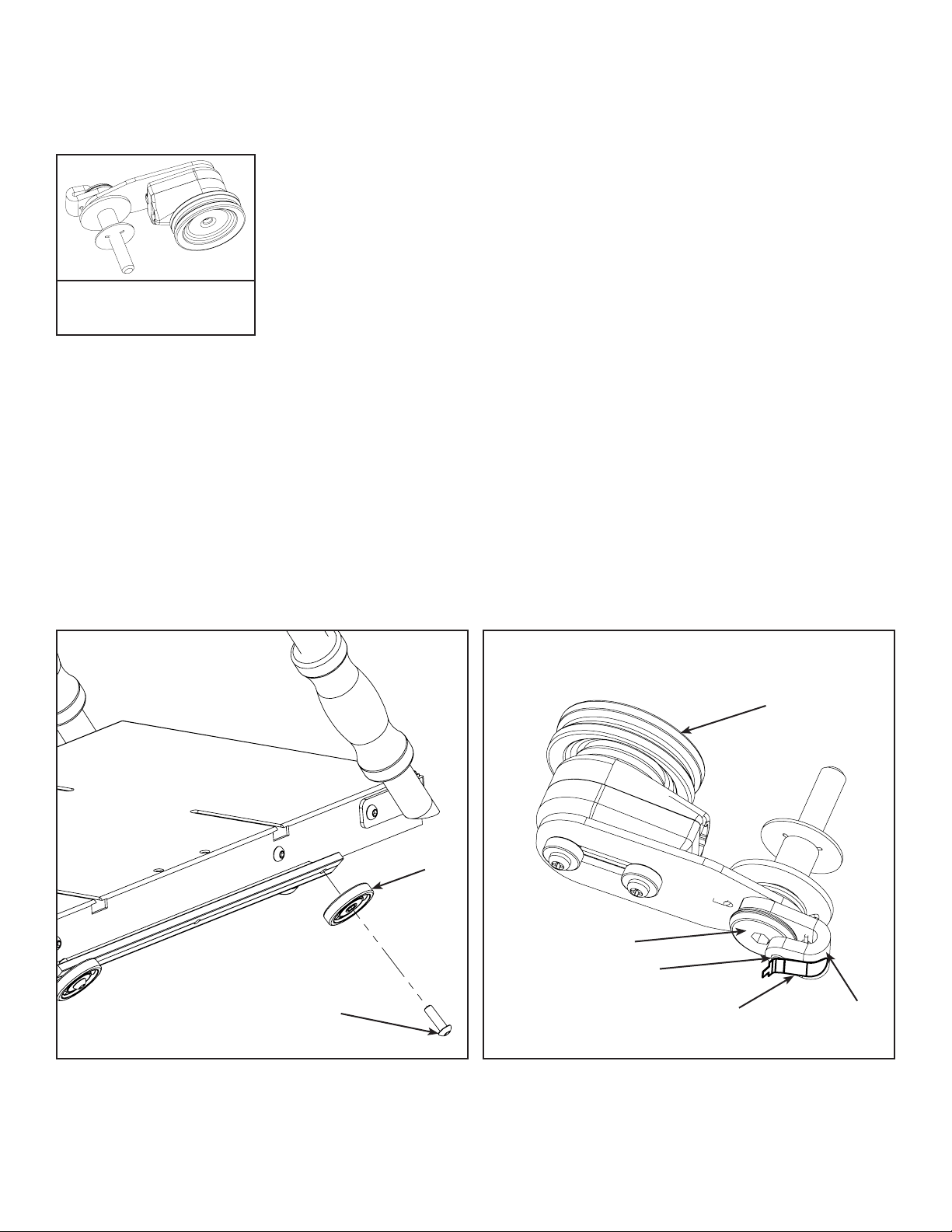

Step 1: Bottom Carriage .............................................................................................................. 1

Step 2: Top Carriage.................................................................................................................... 3

Step 3: Control Box Installation .................................................................................................... 5

Operation Instructions ............................................................................................................... 10

Troubleshooting ........................................................................................................................ 11

Dual Wheel Carriage

Step 1: Bottom Carriage ............................................................................................................ 12

Step 2: Top Carriage.................................................................................................................. 13

Step 3: Control Box Installation .................................................................................................. 15

Operation Instructions ............................................................................................................... 21

Troubleshooting ........................................................................................................................ 22

Pro Carriage

Step 1: Bottom Carriage ............................................................................................................ 23

Step 2: Top Carriage.................................................................................................................. 23

Step 3: Control Box Installation .................................................................................................. 25

Operation Instructions ............................................................................................................... 32

Troubleshooting ........................................................................................................................ 33

G-Series 2 Dual

Step 1: Bottom Carriage ............................................................................................................ 34

Step 2: Top Carriage.................................................................................................................. 36

Step 3: Control Box ................................................................................................................... 38

Step 4: Display Console Installation ............................................................................................ 41

Operation Instructions ............................................................................................................... 44

Troubleshooting ........................................................................................................................ 45

G-Series 2 Single

Step 1: Bottom Carriage ............................................................................................................ 46

Step 2: Top Carriage.................................................................................................................. 48

Step 3: Control Box ................................................................................................................... 50

Step 3: Display Console Installation ............................................................................................ 53

Operation Instructions ............................................................................................................... 56

Troubleshooting ........................................................................................................................ 57

Warranty Information........................................................................................................... 58

|Table of Contents Sure Stitch

ii