Installation

3A8861C 7

Installation

Prepare the Pump

Always complete the following procedure before

performing any service or repair to the equipment.

1. Relieve the pressure. Follow the Pressure Relief

Procedure in your related pump manual. See

Related Manuals, page 2.

2. Verify that the pump is turned off and power to the

system is disconnected before performing any

service or repair procedure.

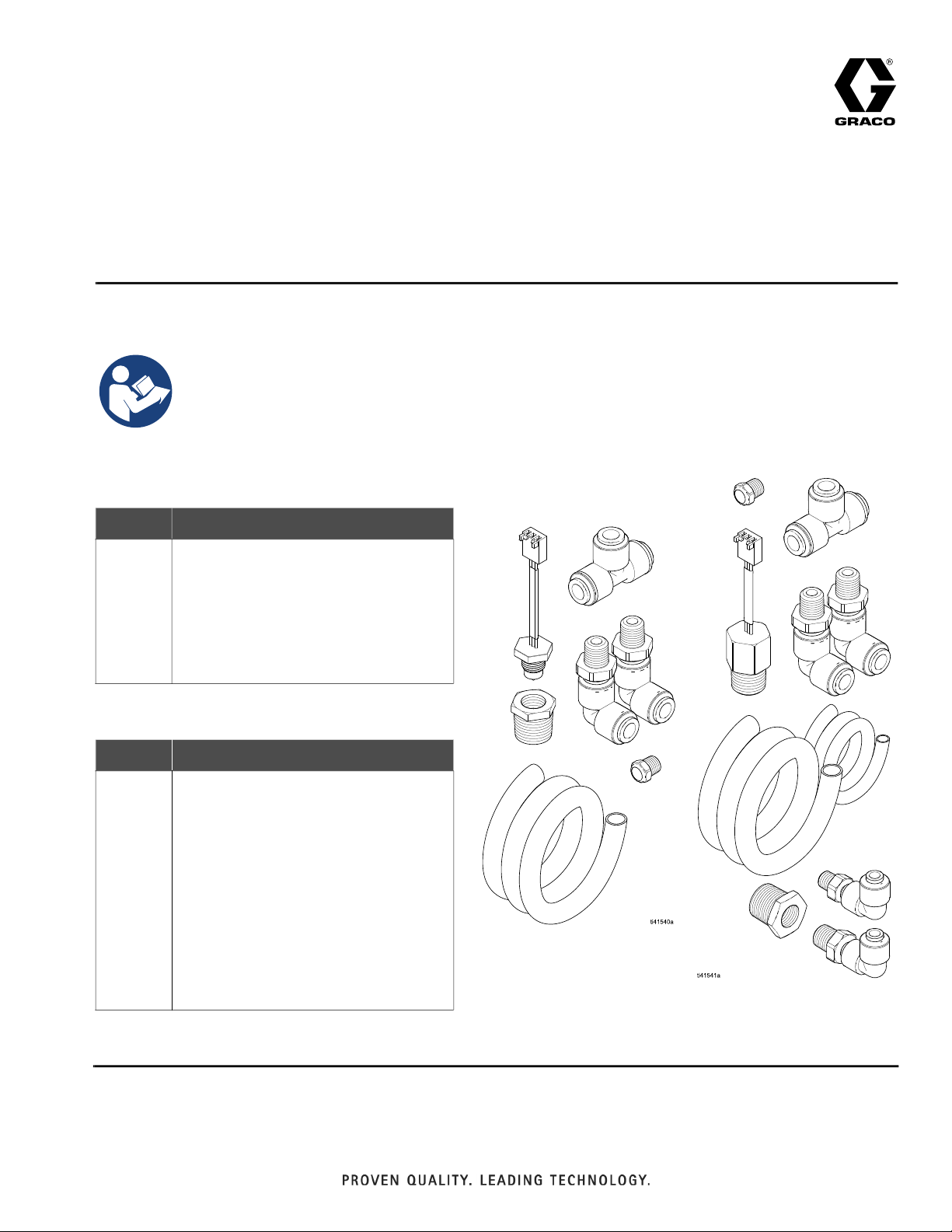

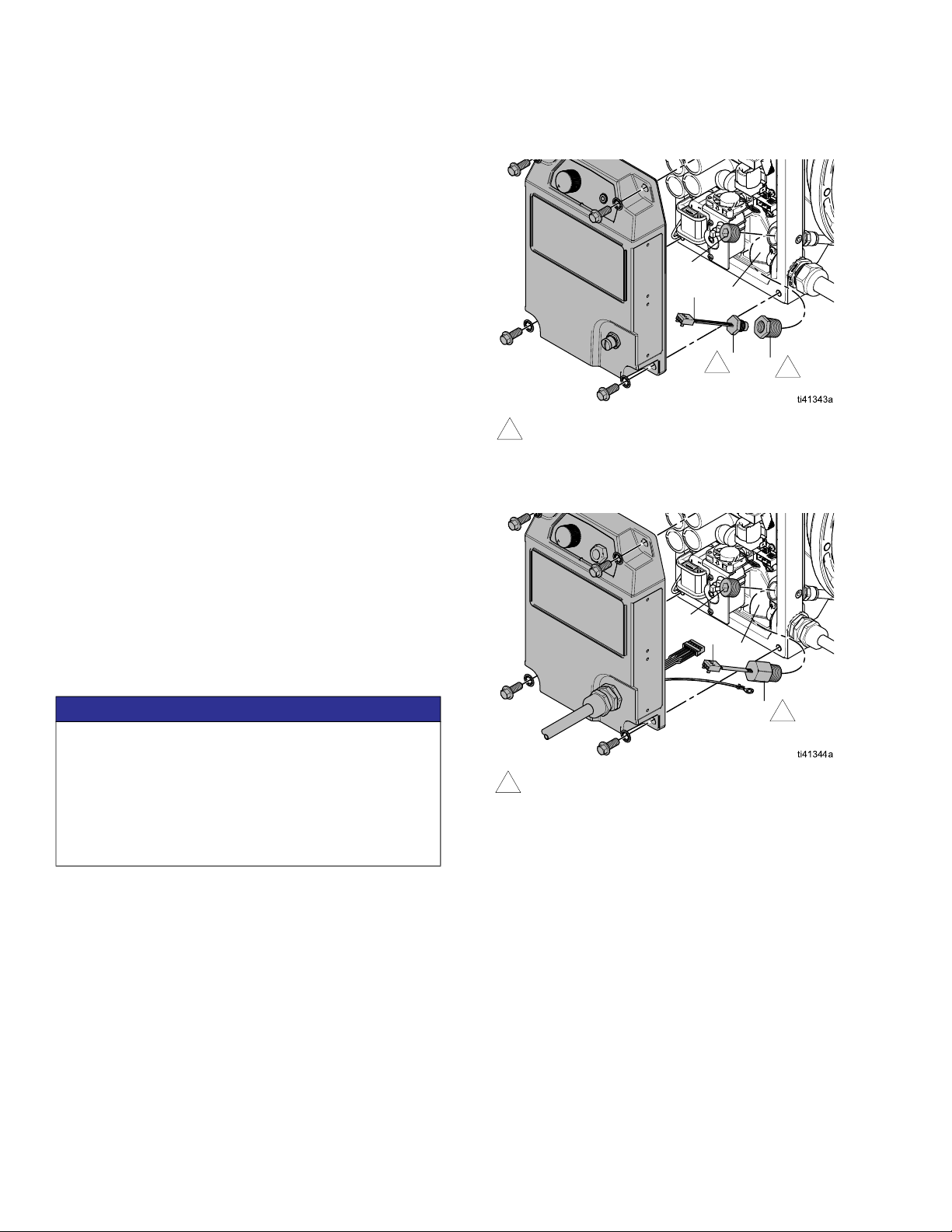

Install the Leak Sensor

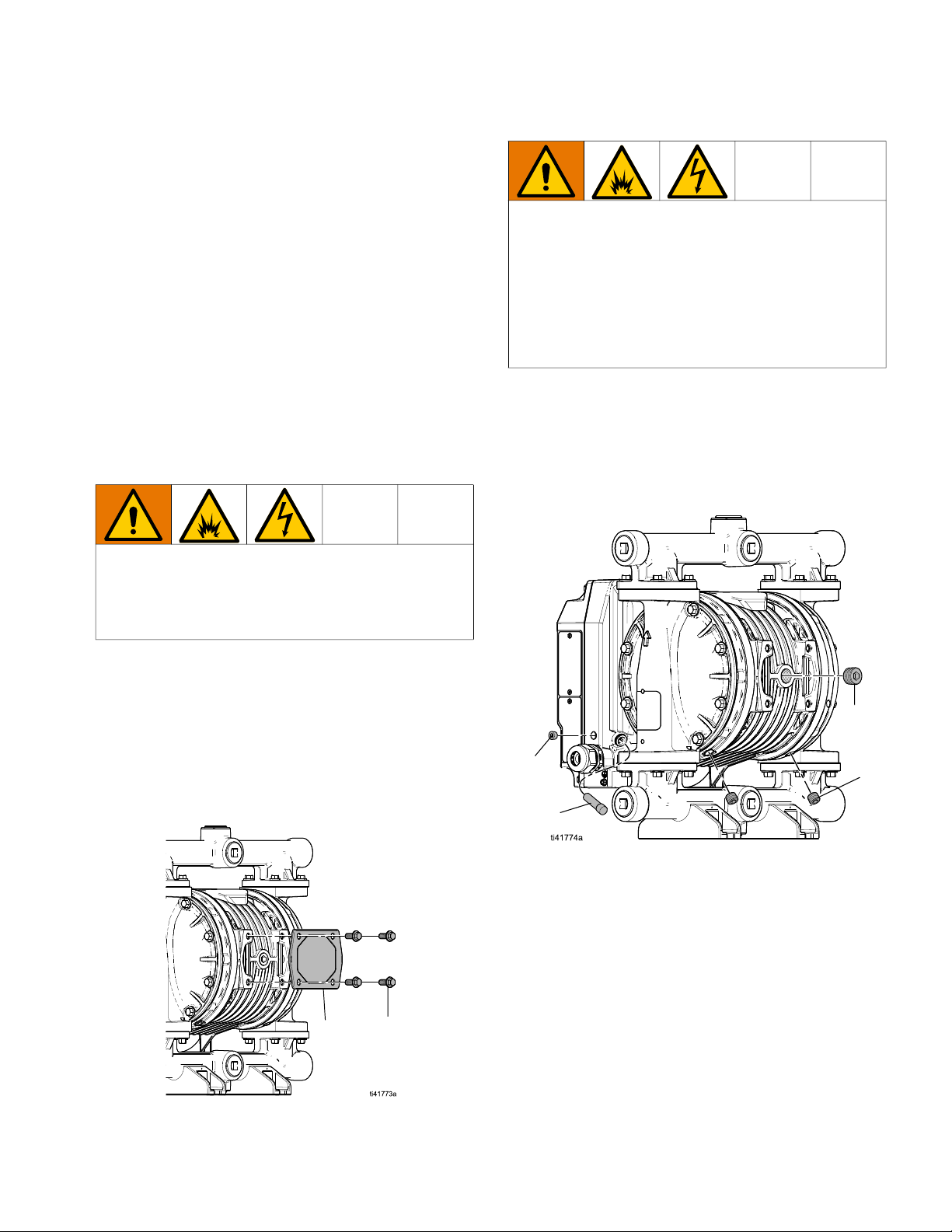

See FIG. 3–FIG. 4.

Required Tools:

• 7/8 in. open-end wrench

• 3/8 in. hex wrench

• 3/4 in. open-end wrench (for pumps certified for

use in Ordinary Locations only)

Remove the Leak Sensor

If a leak sensor is currently installed, remove the current

leak sensor before installing the new leak sensor.

1. Follow Prepare the Pump, page 7.

2. Remove the control cover. See your related motor

manual. See Related Manuals, page 2.

3. Disconnect the leak sensor wire (A) from the port in

the control housing (S). See Electrical

Schematics, page 13.

4. Pumps Certified for Use in Ordinary Locations

only: Loosen the fitting (B) behind the leak sensor

(C).

5. Remove the leak sensor (C) assembly and reducer

fitting (B, if applicable) from the control housing (S).

NOTE: Ensure there is no fluid in the leak sensor or

in the control housing.

6. Pumps Certified for Use in Ordinary Locations

only: Disconnect the fitting (B) from the leak

sensor (C).

7. Disconnect the hoses (F, H, if applicable) and

fittings (D, J, if applicable, K, if applicable, N, if

applicable) from the pump.

8. Inspect for wear or damage. Replace as necessary.

To avoid injury from fire, explosion, or electric

shock, all electrical wiring must be done by a

qualified electrician and comply with all local codes

and regulations.

To prevent electric shock, turn off the pump and

disconnect from power before performing any

service or repair procedure.

To help prevent serious injury from pressurized fluid,

such as skin injection, splashing fluid and moving

parts, relieve the pressure when you stop operating

and before cleaning, checking, or servicing the

equipment. Follow the Pressure Relief Procedure in

your related pump manual. See Related Manuals,

page 2.

Perform Prepare the Pump, page 7, before

performing any service or repair.

Pumps Certified for Use in Explosive

Atmospheres or Hazardous (Classified)

Locations: To avoid injury from fire and explosion,

move the equipment to a non-explosive or

non-hazardous location before performing any

service or repair to the equipment.

To avoid injury from electric shock, all electrical

wiring must be done by a qualified electrician and

comply with all local codes and regulations.

NOTICE

To avoid damage to the control board, ensure that

fluid does not contact electrical components in the

control housing.