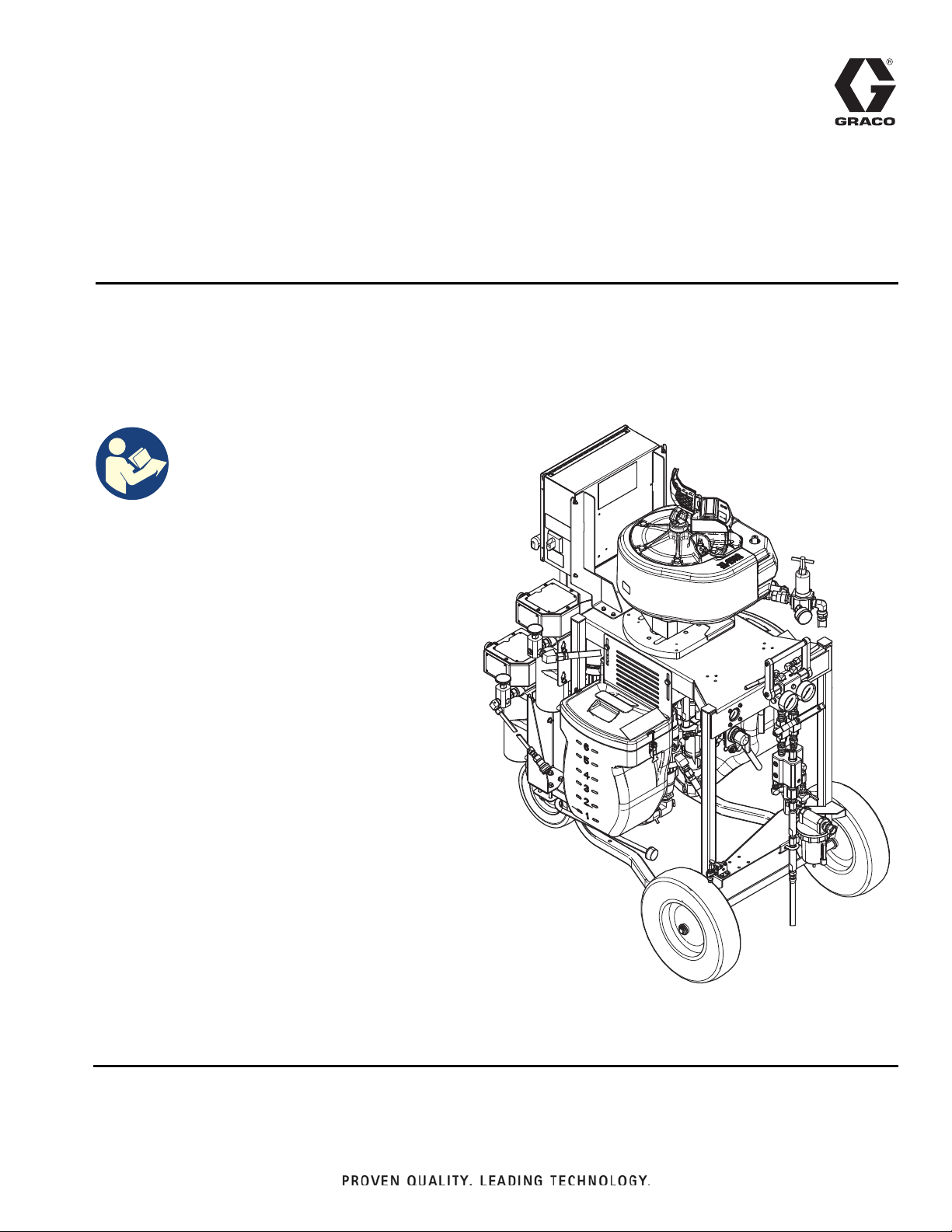

23A0420ZAF

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Important Isocyanate (ISO) Information . . . . . . . . . . . . . . 7

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . . . . . 7

Keep Components A and B Separate . . . . . . . . . . . . . . 7

Moisture Sensitivity of Isocyanates . . . . . . . . . . . . . . . . 8

Changing Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Over Pressure Protection . . . . . . . . . . . . . . . . . . . . . . . 9

Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Series Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

XP Proportioning Pump Packages . . . . . . . . . . . . . . . 10

XP Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

XP50-h with Viscount II Hydraulic Motor, Series C . . . 13

XP70-h with Viscount II Hydraulic Motor, Series C . . . 14

XP Proportioning Pump Packages . . . . . . . . . . . . . . . 15

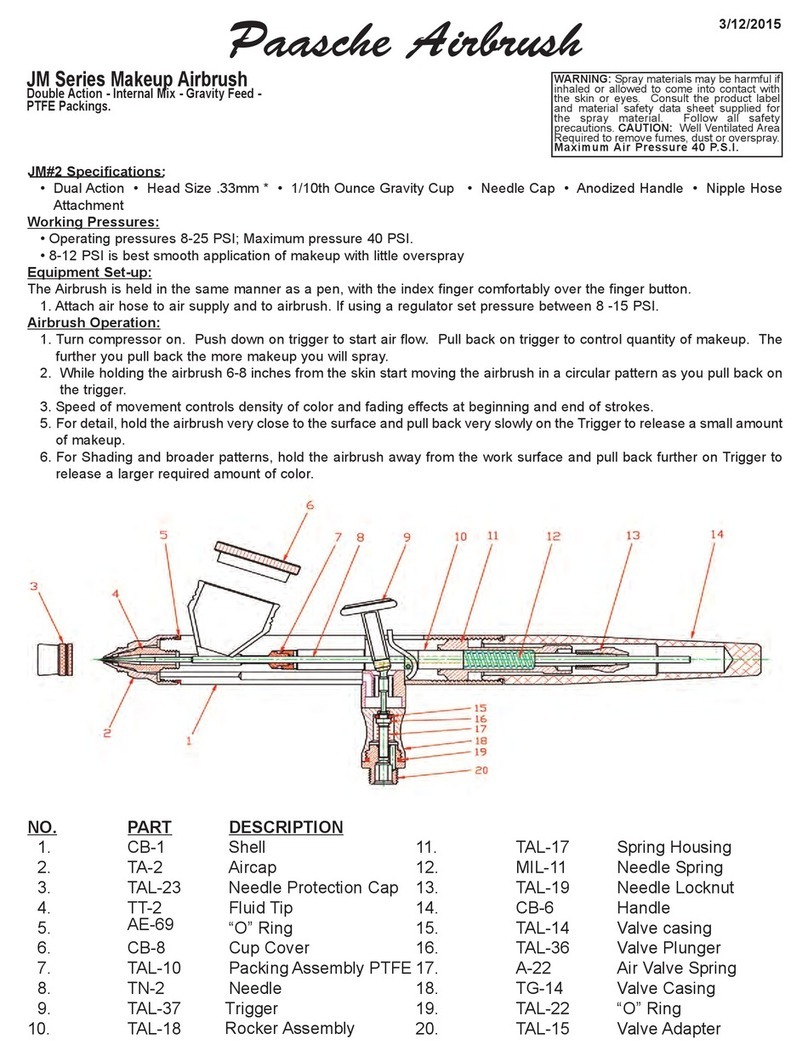

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . 16

XP Proportioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

XP-h Proportioners . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fluid Control Assembly . . . . . . . . . . . . . . . . . . . . . . . . 18

Main Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

45:1 Solvent Flush Pump Kit 262393 (optional) . . . . . 19

System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

*Bleed Type Motor Air Valve (MA) . . . . . . . . . . . . . . . 20

*Air Pressure Relief Valve (MG) . . . . . . . . . . . . . . . . . 20

*Air Filter (MC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

*Air Regulator (MB) . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fluid Line Components . . . . . . . . . . . . . . . . . . . . . . . . 21

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Initial System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Flush Before Using Equipment . . . . . . . . . . . . . . . . . . 22

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connect Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Systems with Explosion-Proof Heaters . . . . . . . . . . . . 25

Motor Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connect Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connect Hydraulic Supply/Return Lines . . . . . . . . . . . 27

Connect Static Mixers, Gun, and Hoses . . . . . . . . . . . 27

Connect Jacketed Heated Hose . . . . . . . . . . . . . . . . . 28

Connecting Additional Hose Lengths . . . . . . . . . . . . . 28

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . 30

Prime Empty System . . . . . . . . . . . . . . . . . . . . . . . . . 31

Prime Solvent Flush Pump . . . . . . . . . . . . . . . . . . . . . 33

Recirculate Prior to Spraying or

Re-Prime After a Pump Runs Dry . . . . . . . . . . . . 34

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

B Component Adjustable Fluid Restrictor . . . . . . . . . . 36

Flush Mixed Material . . . . . . . . . . . . . . . . . . . . . . . . . 37

Empty and Flush Entire System

(new system or end of job) . . . . . . . . . . . . . . . . . 39

Park . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

System Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cleaning Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Change the Mix Ratio . . . . . . . . . . . . . . . . . . . . . . . . . 44

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Mix Manifold Assembly . . . . . . . . . . . . . . . . . . . . . . . . 51

Fluid Circulation Manifold with

Over Pressure Relief Valves . . . . . . . . . . . . . . . . 51

Hoppers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Solvent Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Fluid Heaters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

System Common Parts . . . . . . . . . . . . . . . . . . . . . . . . 55

Parts Varying by Model . . . . . . . . . . . . . . . . . . . . . . . 56

Parts Varying by Model (continued) . . . . . . . . . . . . . . 57

Air Controls, 26C417 . . . . . . . . . . . . . . . . . . . . . . . . . 69

Fluid Circulation Manifold with

Over Pressure Relief Valve . . . . . . . . . . . . . . . . . 70

Hose Heater (bracket mounted) . . . . . . . . . . . . . . . . . 71

Heated Hose Recirculation Pump . . . . . . . . . . . . . . . 73

Solvent Pump Parts . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Solvent Air Control Parts . . . . . . . . . . . . . . . . . . . . . . 75

Heater Block Remote Manifold Kit . . . . . . . . . . . . . . . 76

PressureTrak Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

XPh Proportioning Pump Package . . . . . . . . . . . . . . . 78

XP Proportioning Pump Package . . . . . . . . . . . . . . . . 80

Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . 82

Accessories and Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Acceptable For Use in Explosive

Atmospheres/Hazardous Locations . . . . . . . . . . 83

Not Approved For Explosive Atmospheres . . . . . . . . . 84

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Pump Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 91

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . 94