Installation

Installation Installation

Installation

Before Before

BeforeInstalling Installing

Installingthe the

theKit Kit

Kit

•Servicingtheelectricalcontrolboxexposesyou

tohighvoltage.Toavoidelectricshock,turnoff

poweratthemaincircuitbreakerbeforeopening

theenclosure.

•Allelectricalwiringmustbedonebyaqualied

electricianandcomplywithalllocalcodesand

regulations.

•Thisequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock,which

couldcausefumestoigniteorexplode.See

Grounding,page16.

FollowthePressureReliefProcedurein

yourPD2Kmanualwheneveryousee

thissymbol.

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduidsuchasskininjection,

splashinguid,andmovingparts,followthe

Pressure Pressure

PressureRelief Relief

ReliefProcedure Procedure

Procedureinyoursystemmanual

whenyoustopsprayingandbeforecleaning,

checking,orservicingtheequipment.

1.FlushthesystemasexplainedinyourPD2K

OperationManual.FollowthePressureRelief

ProcedureinyourPD2Kmanual.

2.Closethemainairshutoffvalveontheairsupply

line.

3.Removeelectricalpowerfromthesystem.

Install Install

Installthe the

thePump Pump

Pump

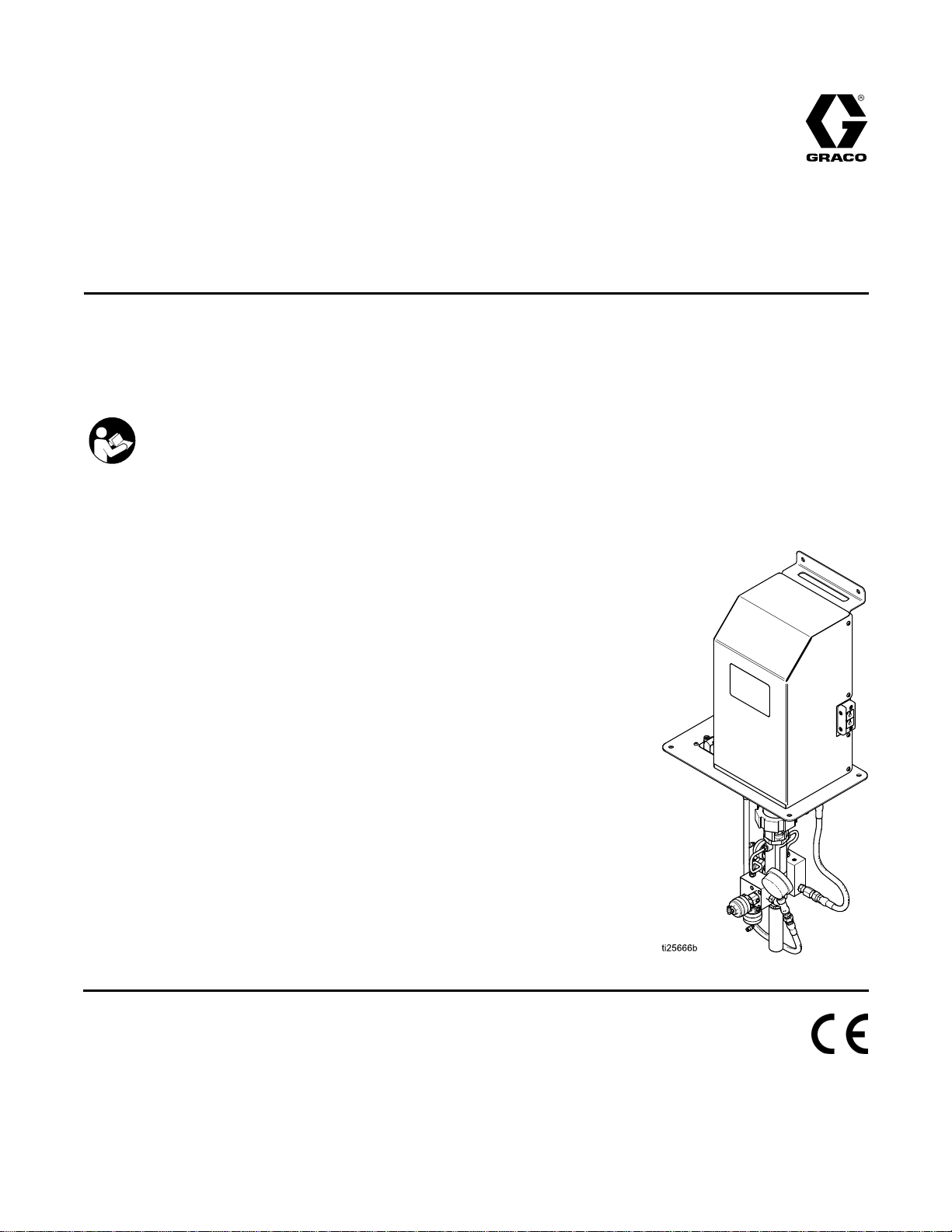

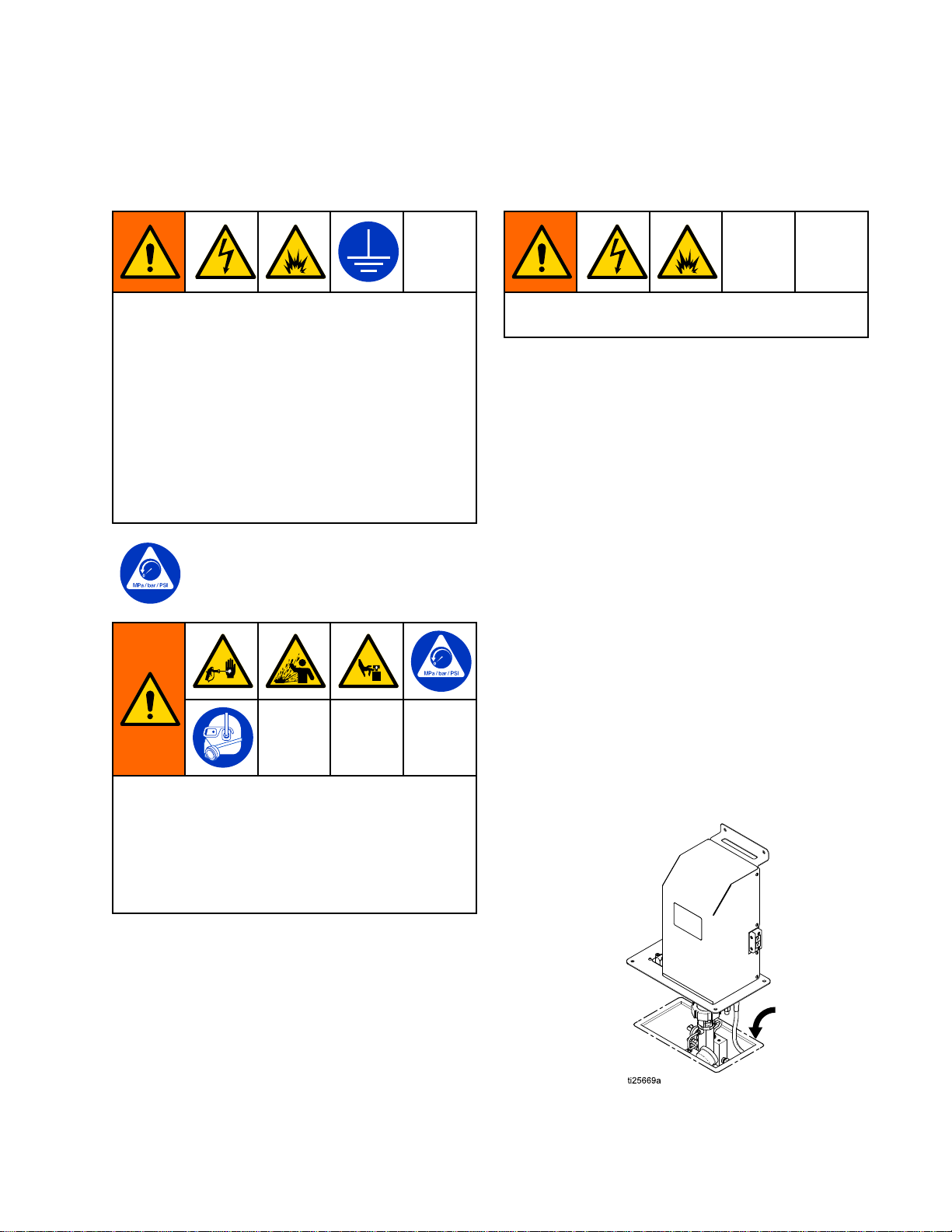

Theelectronicportionofthepumpkitmustremain

outsidethehazardouslocation.SeeFigure2.

1.FollowthestepsinBefore Before

BeforeInstalling Installing

Installingthe the

theKit, Kit,

Kit,inthe

previoussection.

2.Planyourinstallationsothatallpumpsare

locatedwithin6ft.ofthePD2Kelectricalcontrol

box(D).Eachmulti-conductorcable(10)must

beabletoreachfromthedualcablegrommet

(9)tooneoftheportsonthecontrolbox.See

ElectricalConnections,page14.SeealsoFigure

2.

NOTE: NOTE:

NOTE:Tomountpumpsonbothsidesofthe

controlbox,turnthepumpcontrolmodule(6)

over,andconnectthedualcablegrommet(9)on

theothersideoftherearmountingbracket.

3.Installthepumpassemblysecurelybybolting

therearmountingbracket(4)todesiredwallor

sturdysurface.SeeDimensions,page32.

4.Applyapprovedreproofsealanttothemating

surfaceofthemountingplate(1),toensure

anairtightseal.Mounttheplateonthe

horizontalsurfacethatisthebarrierbetween

thehazardousandnon-hazardousareas.See

Dimensions,page32.

334512C9