Contents

Warnings .............................................................3

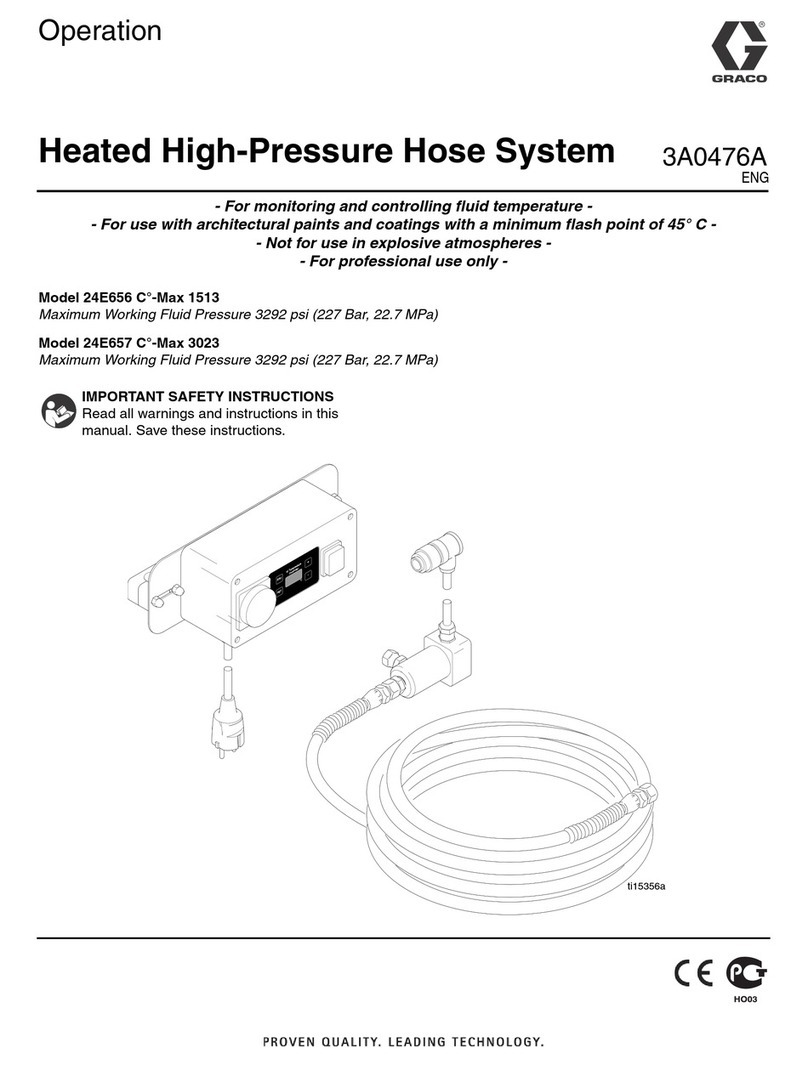

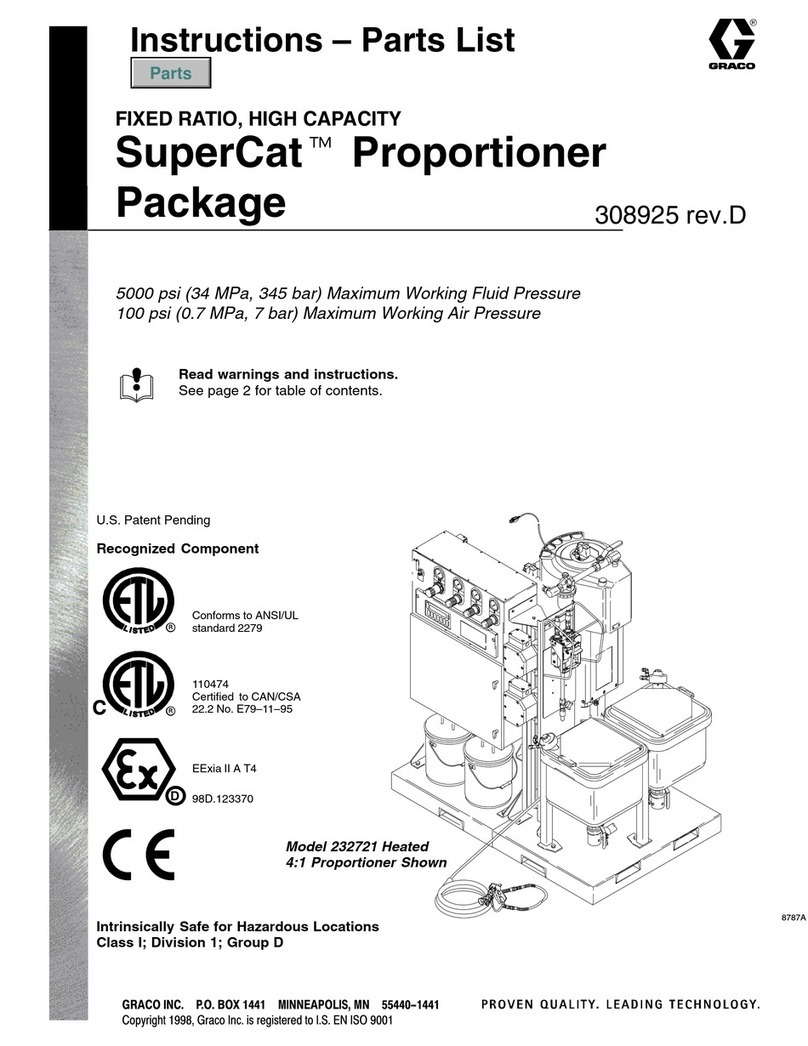

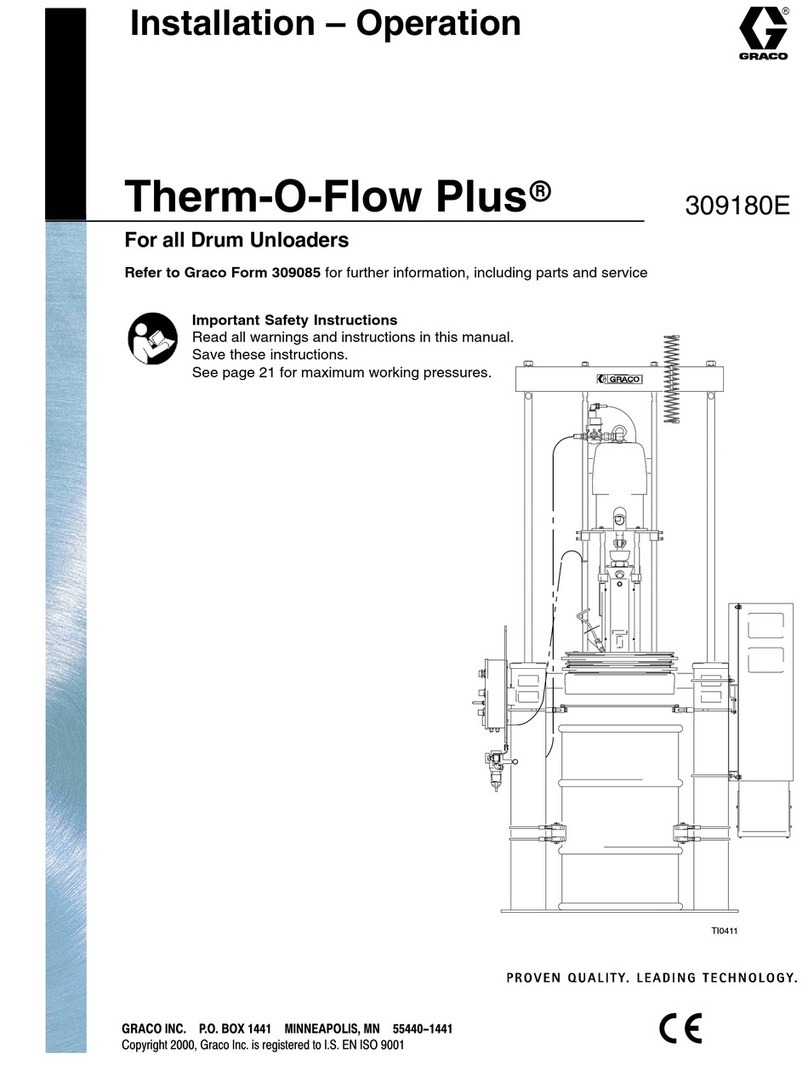

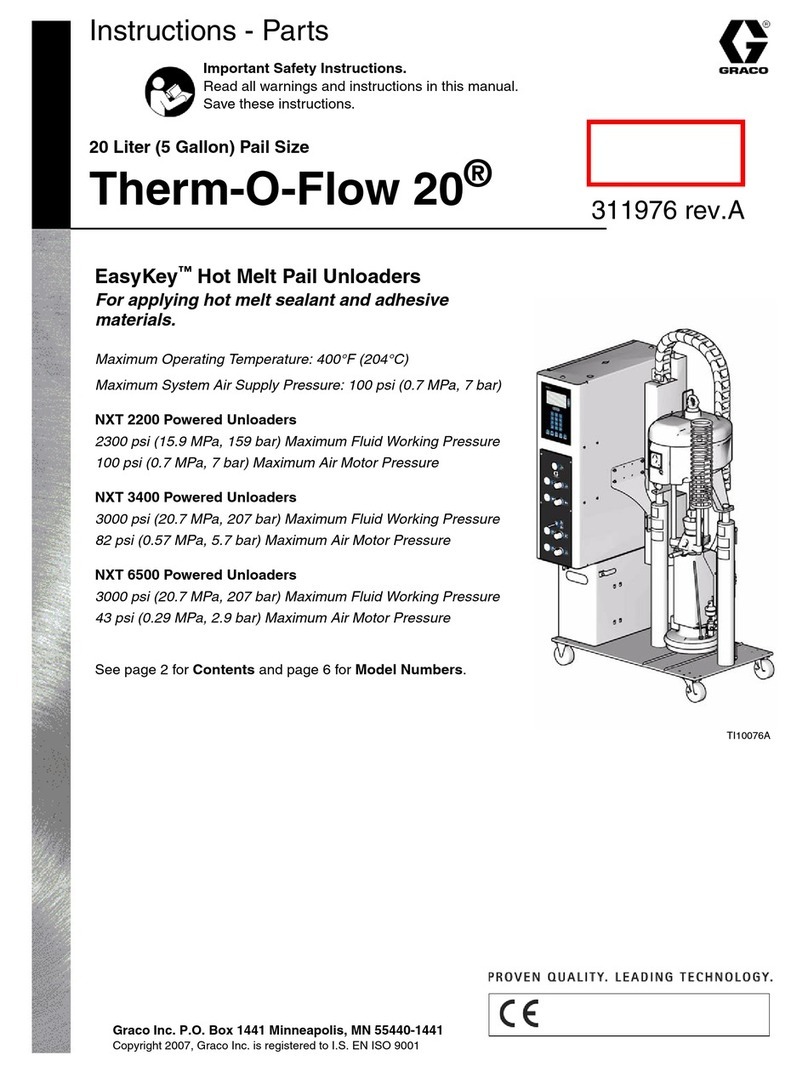

Models.................................................................6

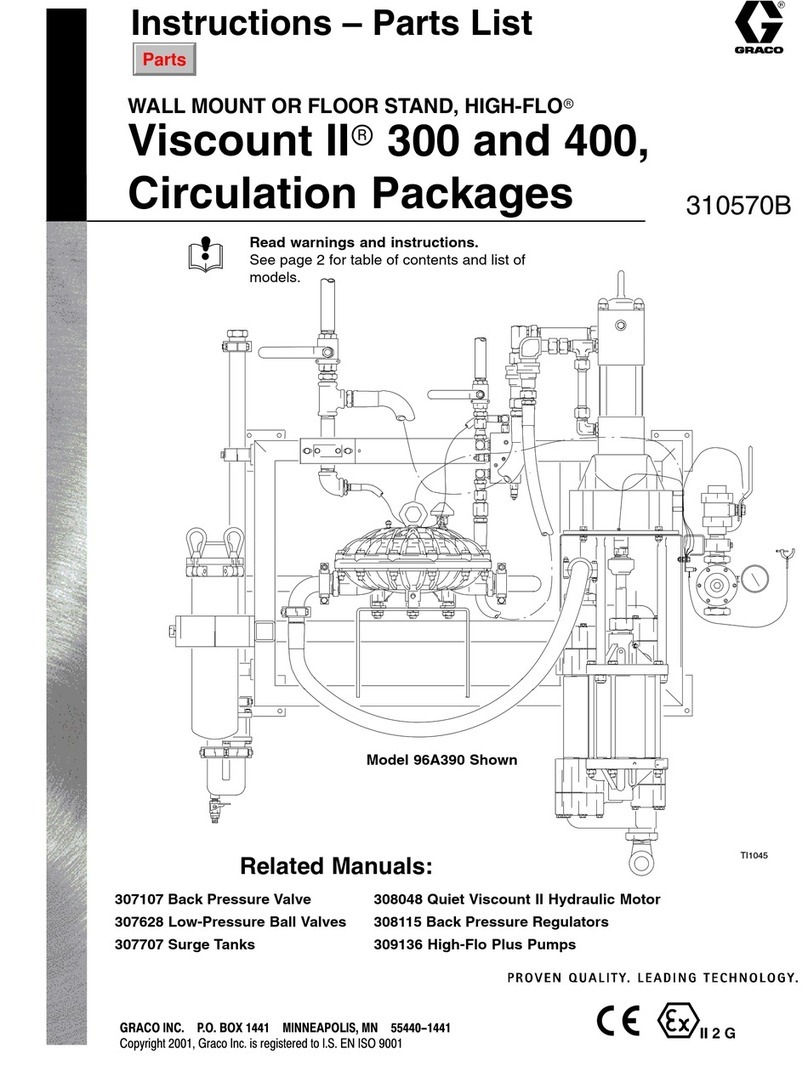

Related Manuals ..................................................7

Component Identification.......................................8

Advanced isplay Module (A M).................. 12

Overview............................................................ 15

Air and Fluid Hoses...................................... 15

Heat Control Zone........................................ 15

Setup................................................................. 16

Unpack........................................................ 16

Location Requirements................................. 16

Install System.............................................. 16

Mechanical Setup ........................................ 17

Install Heated Hose...................................... 18

Connect Multiple evices ............................. 20

Connect Power............................................ 21

Grounding ................................................... 22

Connect Secondary System.......................... 22

Check Sensor Resistance ............................ 23

Check Heater Resistance............................. 24

Select A M Settings .................................... 25

Connect PLC............................................... 27

Operation........................................................... 30

Purge System.............................................. 30

Load Material............................................... 31

Heat Up System........................................... 32

Prime Pump ................................................ 33

Prime System.............................................. 35

Setback Mode.............................................. 35

Pressure Relief Procedure............................ 36

Shutdown.................................................... 37

Schedule..................................................... 37

Change Pail................................................. 38

Troubleshooting.................................................. 39

Repair................................................................ 47

Replace Wipers ........................................... 47

Replace Platen RT .................................... 48

Separate the Air Motor and Pump ................. 49

Remove Platen............................................ 50

Replace Heater Bands and Pump

RT ............................................... 51

Replace MZLP Fuse .................................... 52

Replace MZLP............................................. 52

Replace MZLP aughter Card...................... 54

Replace AWB.............................................. 55

Replace Power Supply ................................. 55

Replace Fan................................................ 56

Replace Transformer.................................... 57

Update Software.......................................... 59

Electrical Schematics.......................................... 60

Parts.................................................................. 66

Accessories and Kits........................................... 87

Wiper Kits.................................................... 87

Applicators and ispense Valves .................. 87

Air-Operated Heated ispense Valves........... 87

Flow Control and Manifolds .......................... 87

Accessory Extension Cables......................... 87

Light Tower Kit, 24W589 .............................. 87

Tie Rod Kits................................................. 87

8 Zone Upgrade Kit Installation..................... 91

12 Zone Upgrade Kit Installation ................... 93

Appendix A— A M............................................. 94

Operation Screens....................................... 96

Setup Screens............................................. 97

Appendix B — USB ata .................................. 102

ownload.................................................. 102

Access Files .............................................. 102

Upload ...................................................... 102

USB Logs.................................................. 103

System Settings File .................................. 103

System Language File................................ 104

Create Custom Language Strings ............... 104

imensions...................................................... 105

Notes ............................................................. 107

Technical Specifications.................................... 108

Graco Standard Warranty.................................. 110

2334129C