Contents Contents

Contents

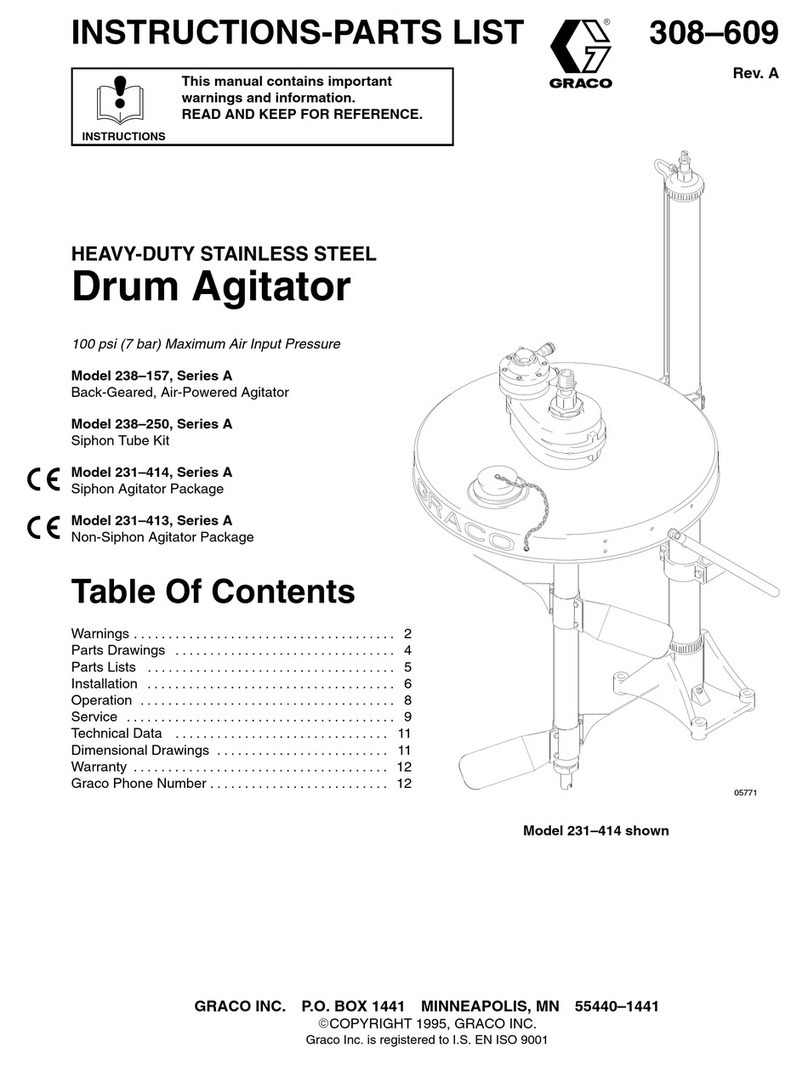

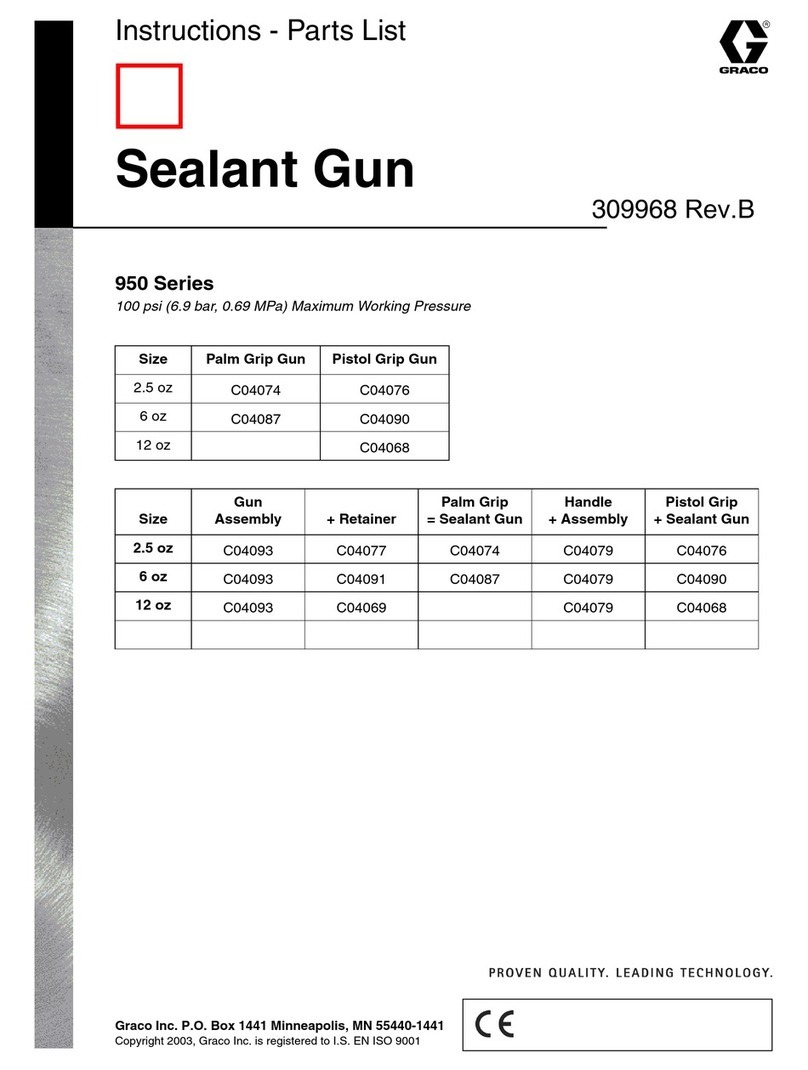

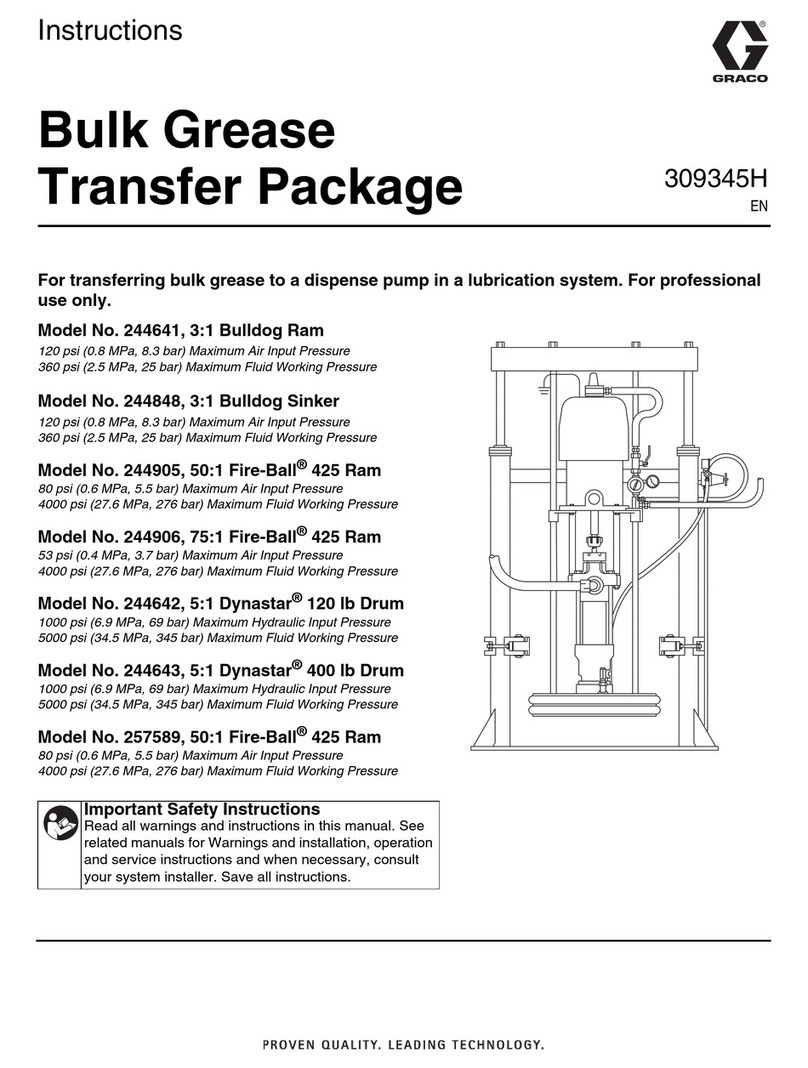

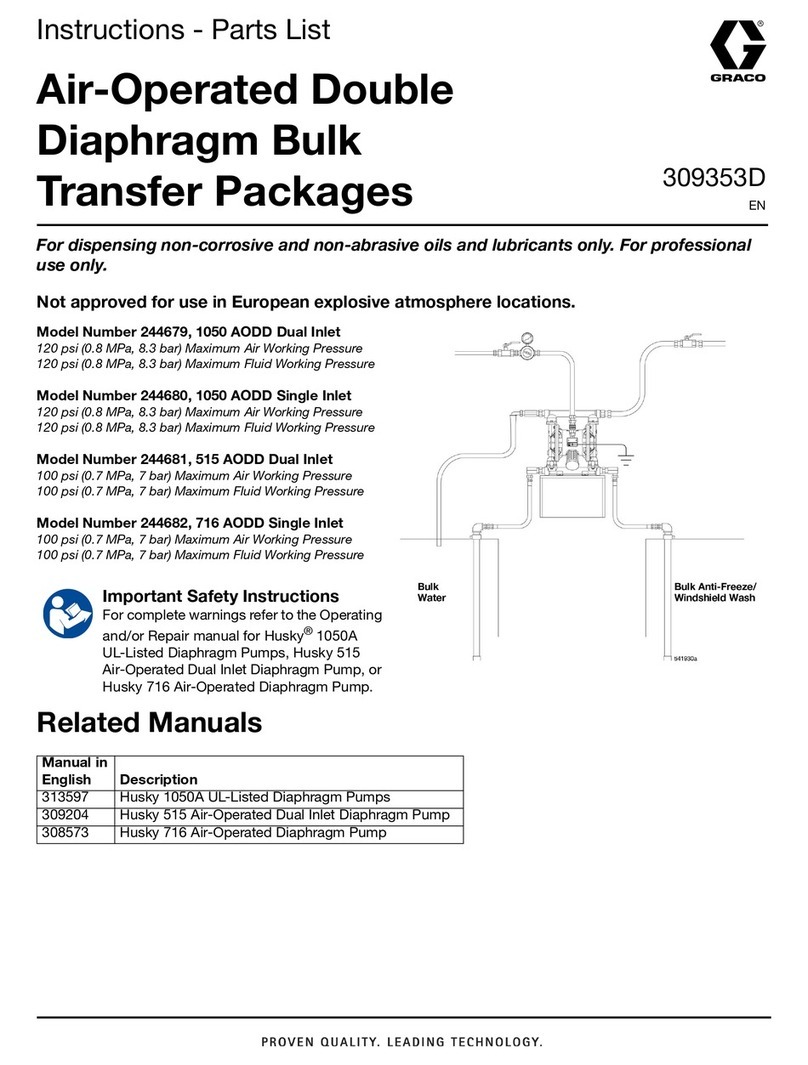

Models...............................................................3

Warnings...........................................................5

Installation..........................................................7

AirRegulatorandMufers............................8

Agitator.......................................................9

Grounding...................................................15

AirLineAccessories.....................................16

AirRequirements.........................................17

Operation...........................................................18

AgitatorOperation........................................18

BackGearOperation....................................18

FindingtheProperAgitatorSpeed................19

PressureReliefProcedure............................19

Maintenance......................................................20

GreasingtheAirMotor.................................20

AirMotorMufer..........................................20

AgitatorBlades............................................20

CleaningtheShaft.......................................21

CleaninganAgitatorwithaSiphonKit...........21

ServicingtheGearReducer..........................21

Service..............................................................23

RemovingtheAirMotor................................23

AligningtheOutletHousing—25C534,

25C535Only..................................24

InspectingtheShaftandAgitatorBlades—

Model25C530Only........................24

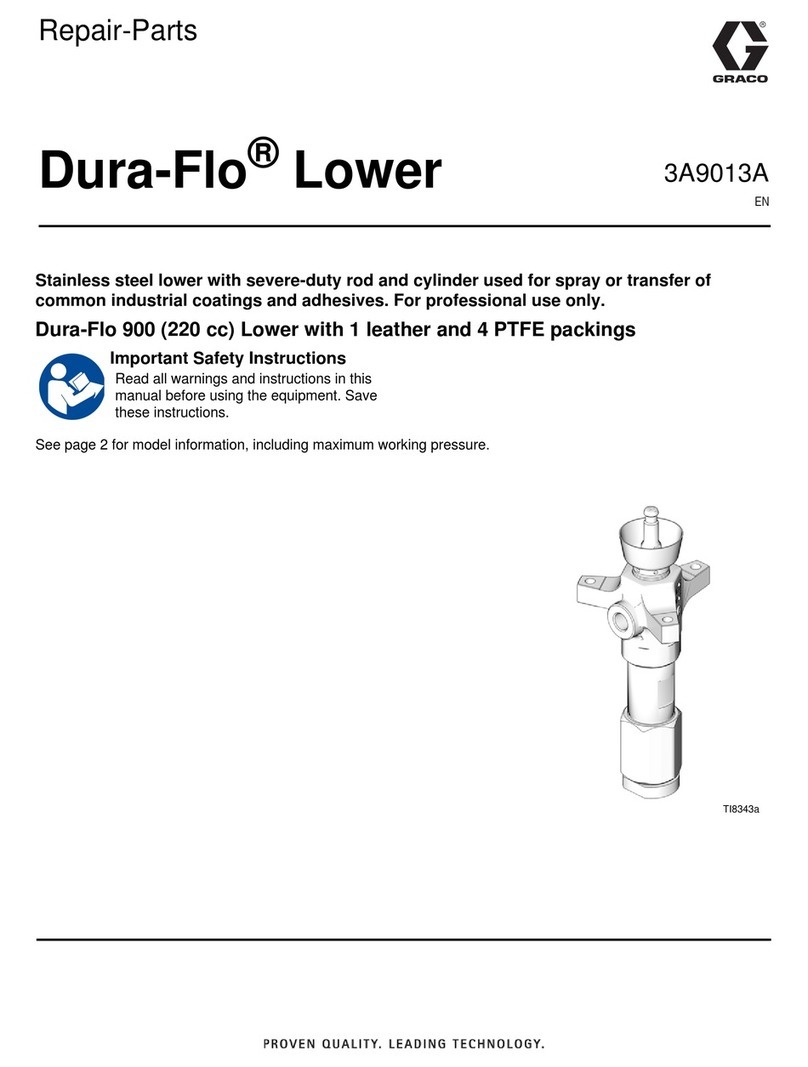

Parts..................................................................25

Model25C528.............................................25

Model25C533.............................................26

Model25M481.............................................27

Model25C529.............................................28

Models25C534,25C535..............................29

Model25C530.............................................30

Models25N881,25N882..............................31

Model19Y592.............................................32

Models26B630,26B631,238250.................33

Models26B618,26B619..............................35

Models26B632,26B633..............................37

Accessories........................................................38

SensorKit25C373.......................................38

DataTrakKit25P394....................................38

Dimensions........................................................39

MountingHoleLayouts.......................................42

AirConsumption.................................................43

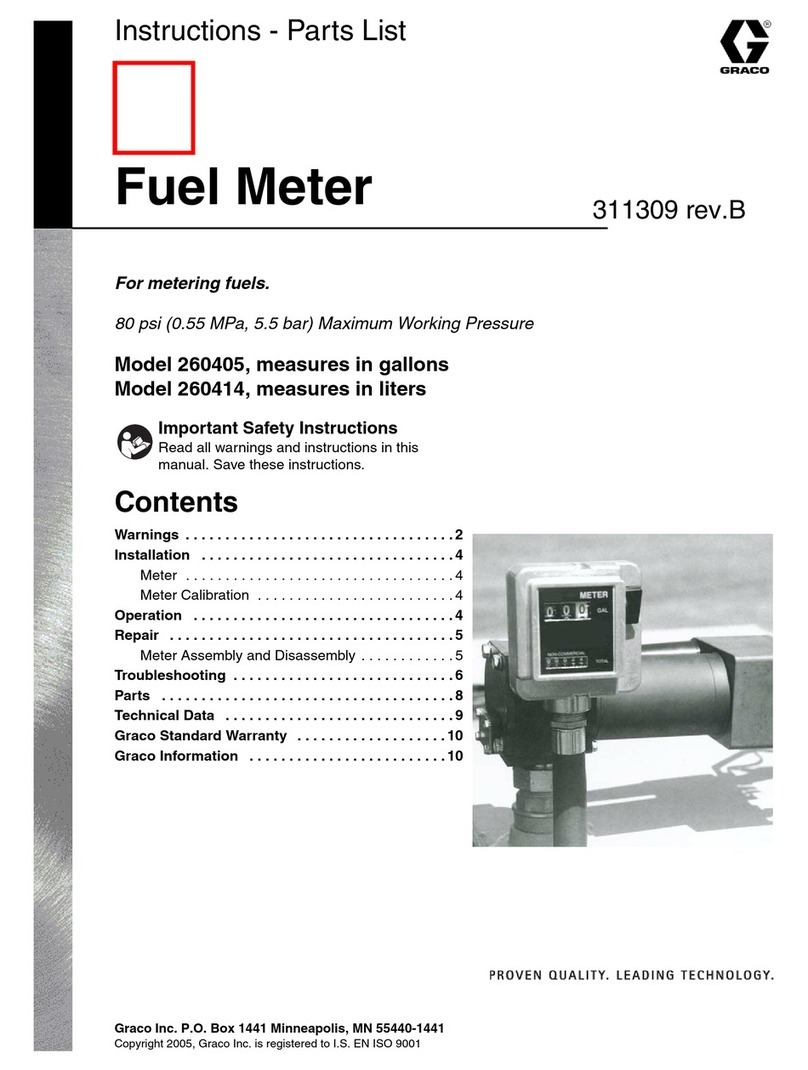

TechnicalSpecications......................................44

Model19Y592.............................................46

Model25C765.............................................46

Models26B618,26B619,26B630,26B631,

26B632,26B633,25T862................46

CaliforniaProposition65.....................................47

Related Related

RelatedManuals Manuals

Manuals

Manual Manual

ManualNumber Number

NumberTitle Title

Title

306287 306287

306287Elevators Elevators

Elevatorsand and

andPump Pump

PumpSupports Supports

Supports

308466 308466

308466Stainless Stainless

StainlessSteel, Steel,

Steel,Passivated Passivated

PassivatedDrum Drum

DrumCovers Covers

Covers

3A5050 3A5050

3A5050Motor Motor

MotorRepair Repair

RepairManual Manual

Manual

306670 306670

306670Air Air

AirDriven, Driven,

Driven,5 5

5Gal. Gal.

Gal.(19 (19

(19Liter) Liter)

Liter)Size Size

SizeAgitators Agitators

Agitators

23A4792G