Warnings

3A5919A 3

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation

point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When these

symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific hazard

symbols and warnings not covered in this section may appear throughout the body of this manual where applicable.

DUST AND DEBRIS HAZARD

Grinding concrete and other surfaces with this equipment can create dust that contains hazardous

substances. Grinding can also create flying debris.

To reduce the risk of serious injury:

• Control the dust to meet all applicable workplace regulations.

• Wear protective eye wear and a properly fit-tested and government approved respirator suitable for

the dust conditions.

• Use equipment only in a well-ventilated area.

• Grinding equipment must be used only by trained personnel who understand the applicable work-

place regulations.

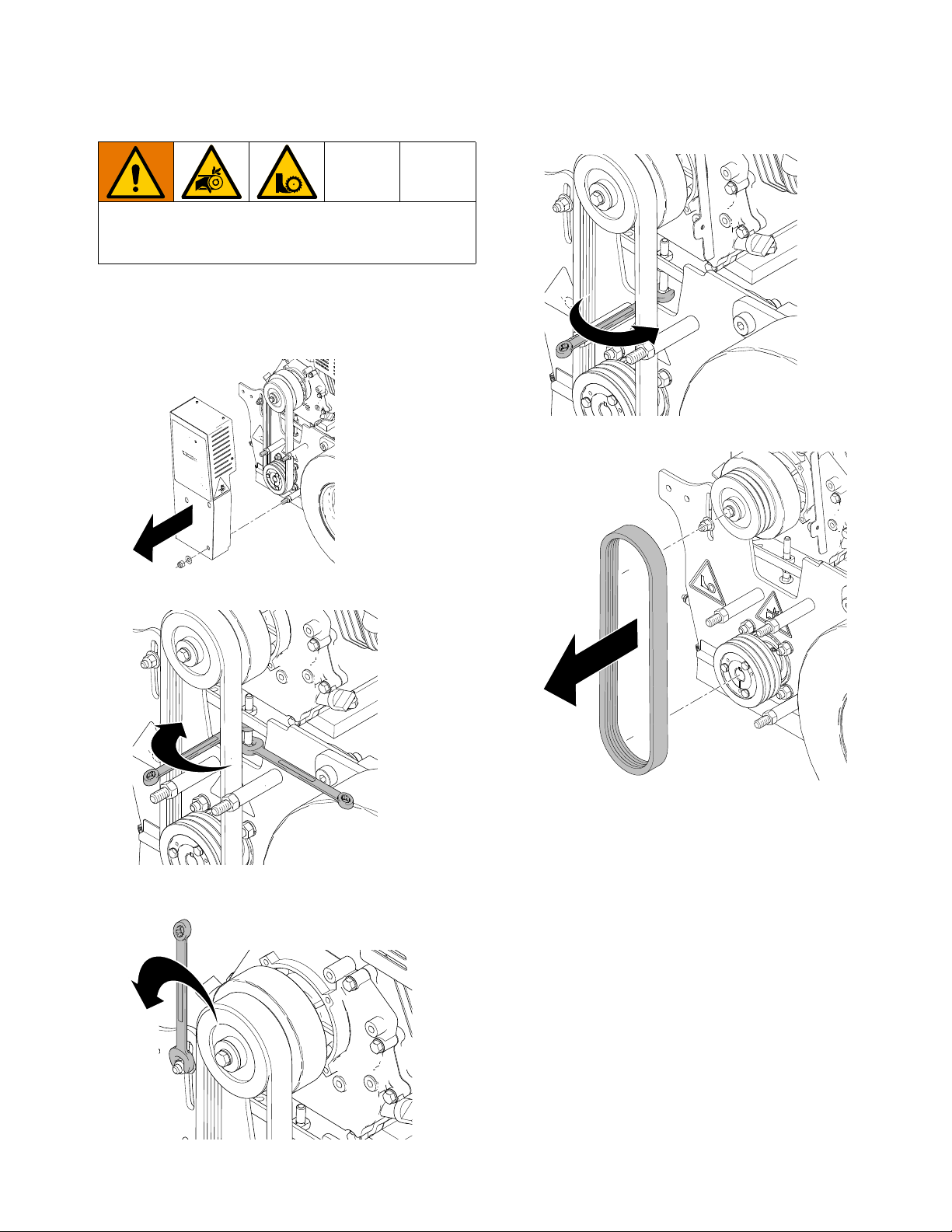

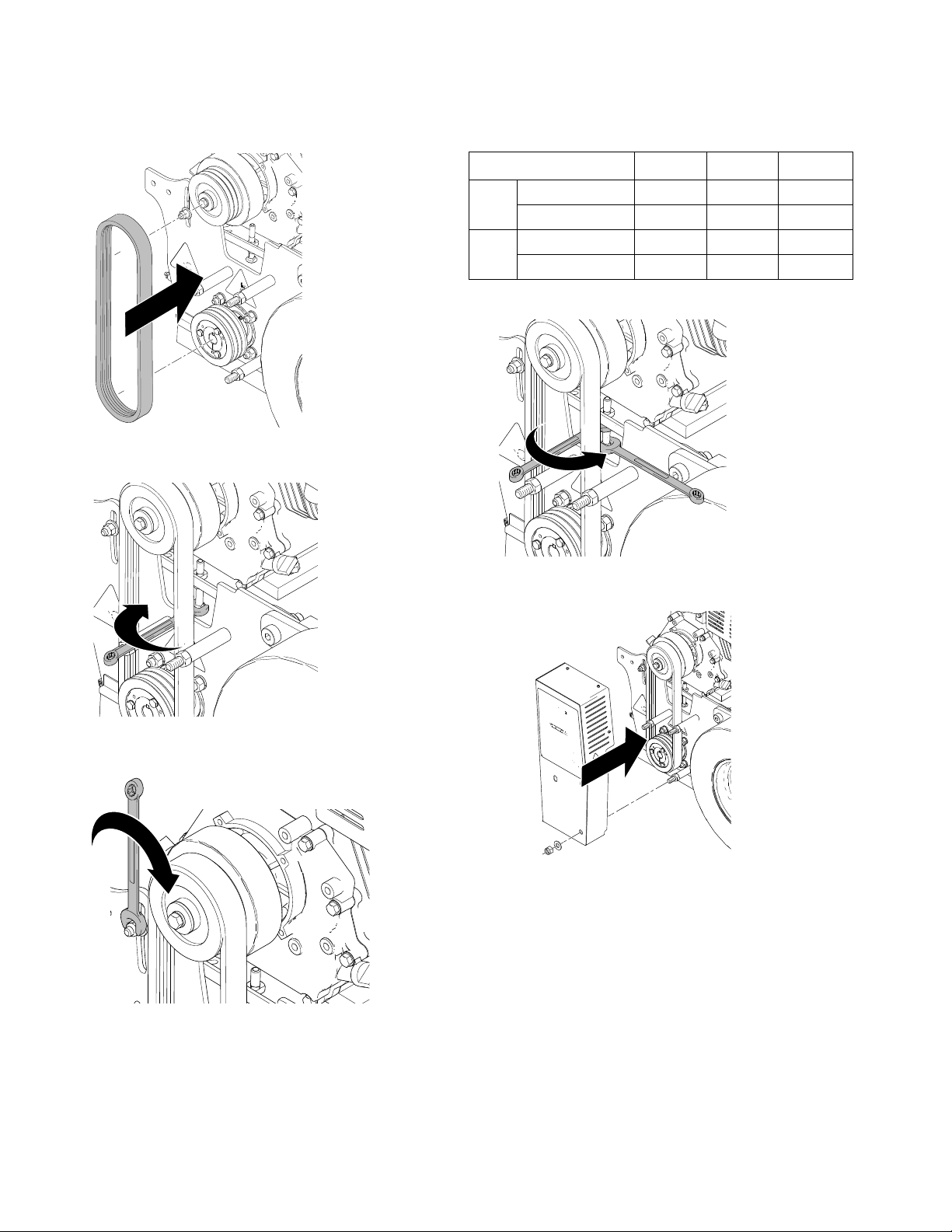

ENTANGLEMENT AND ROTATING PARTS HAZARD

Rotating parts can cut or amputate fingers and other body parts.

• Keep clear of rotating parts.

• Do not operate equipment with protective guards or covers removed.

• Do not wear loose clothing, jewelry or long hair while operating equipment.

• Before checking, moving, or servicing equipment, disable power supply.

BURN HAZARD

Cutters and engine can become very hot during operation. To avoid severe burns, do not touch hot

equipment. Wait until equipment has cooled completely.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not leave the work area while equipment is energized. Turn off all equipment when equipment

is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manu-

facturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

• Maintain a safe operating distance from other people in the work area.

• Avoid any pipes, columns, openings, or any other objects protruding from work surface.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of dust or

chemicals, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear.

• Protective shoes.

• Gloves.

• Hearing protection.

• Properly fit-tested and government approved respirator suitable for the dust conditions.