6

Assembly Instructions

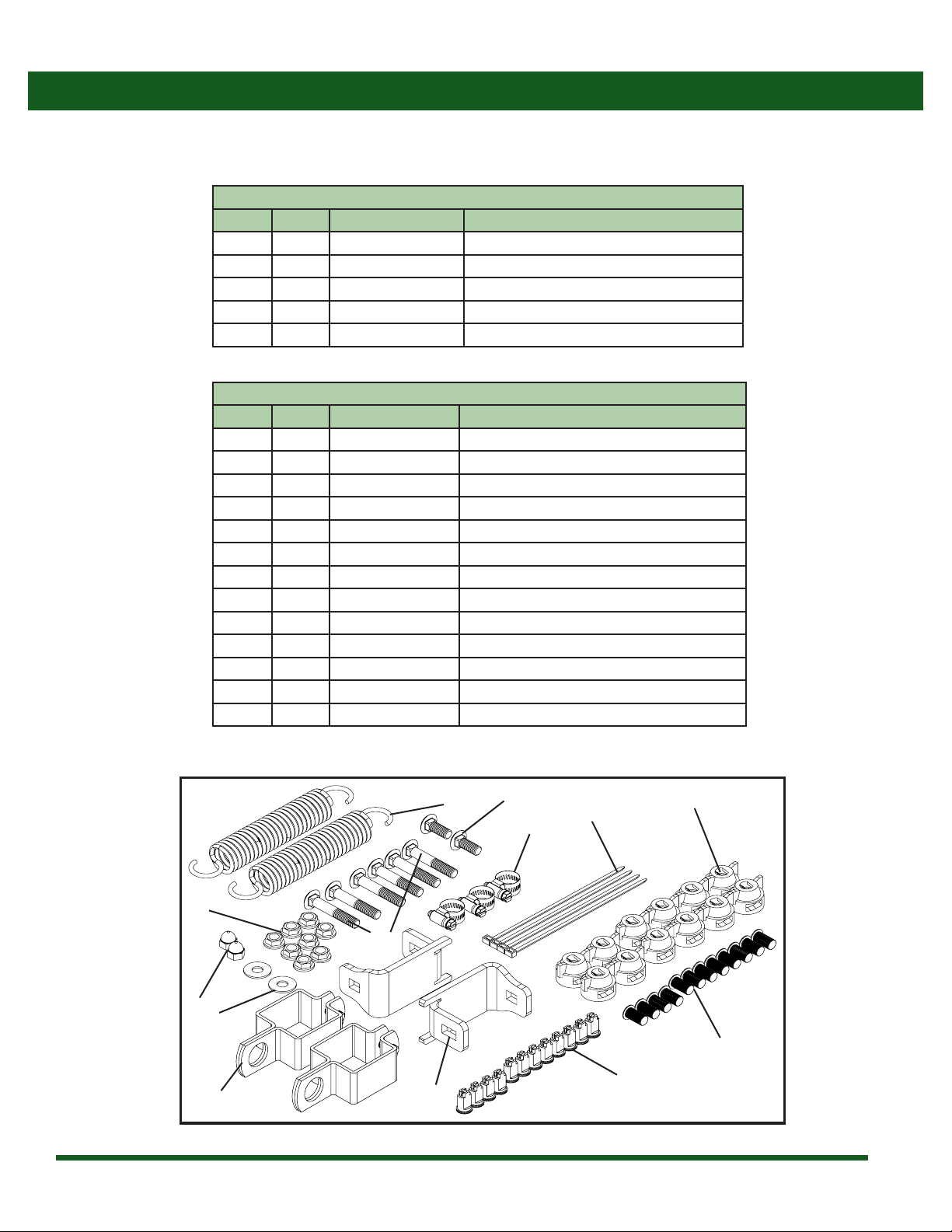

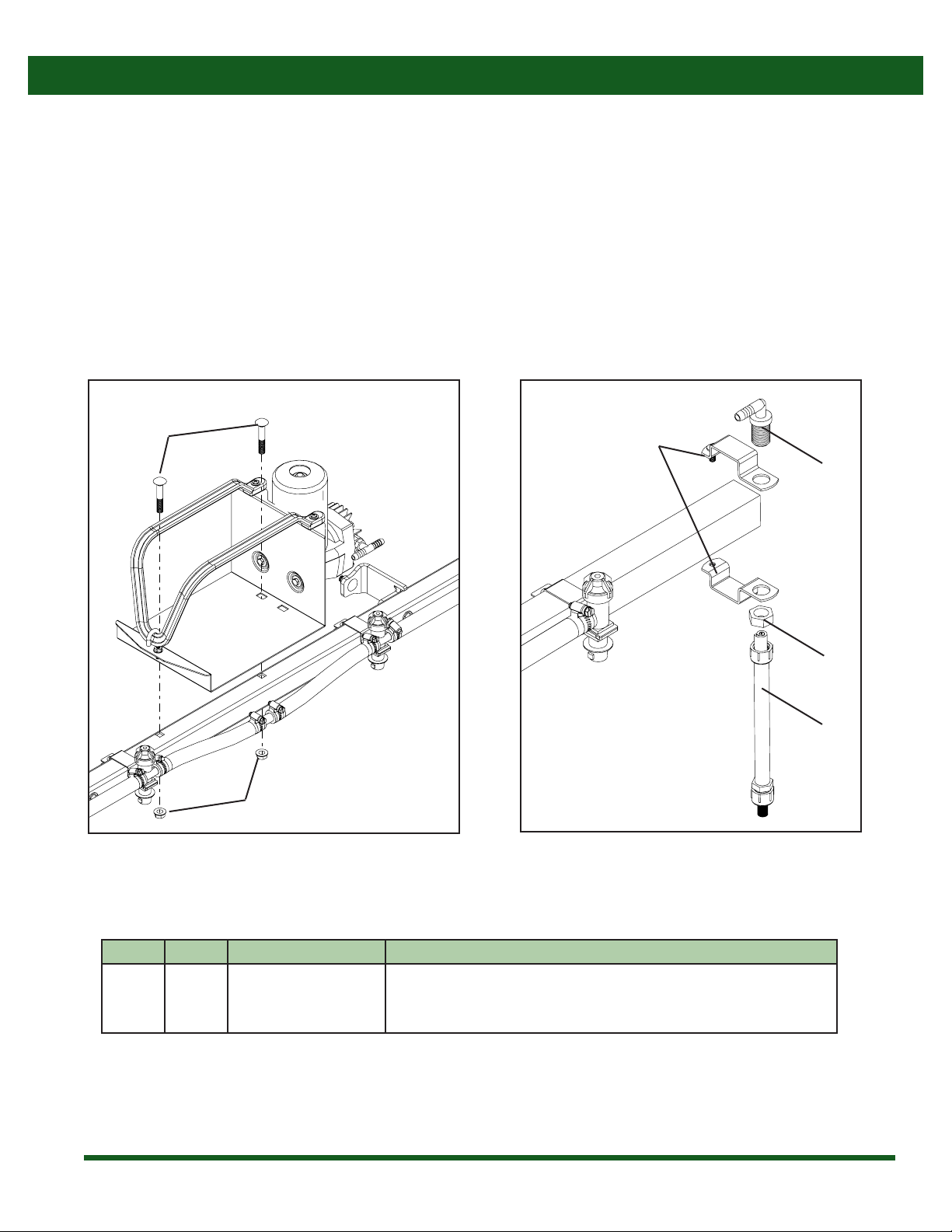

Figure 6: Nozzle assembly

*Included with reference #15 Figure 5: Extension spring mounting

1. Bolt the boom mount brackets (13) (Figure 1 & 3, pg 5 & 6) to

the center frame (1) (Figure 3) using two long carriange bolts

(10) (Figure 1 & 3, pg 5 & 6) and two ange nuts (11) (Figure 1

& 3, pg 5 & 6). Note: The boom mount bracket bent anges

(13) need to be pointed in toward the center of the boom so

that the steel ngers on the brackets slide around the center

frame tube as shown in gure 3.

2. Take the center frame with bolted on boom mount brackets

from step 1 and bolt onto sprayer frame at the desired height

shown in gure 3. Use two carriage bolts (9) (Figure 1 & 3, pg

5 & 6) and two ange nuts (11) (gure 1 & 3, pg 5 & 6).

3. Position the left wing (2) (Figure 4) onto the center frame as

shown in gure 4. Take two long carriage bolts (10) (Figure 1

& 4, pg 5 & 6) and insert them through the hinge plate holes

and center frame holes. Bolt two ange nuts (11) (Figure 1 &

4, pg 5 & 6)onto previously inserted carriage bolts.

4. Bolt at washer (12) and acorn nut (7) (Figure 1 & 5, pg 5 & 6)

onto the vertical wing bolt as shown in gure 5.

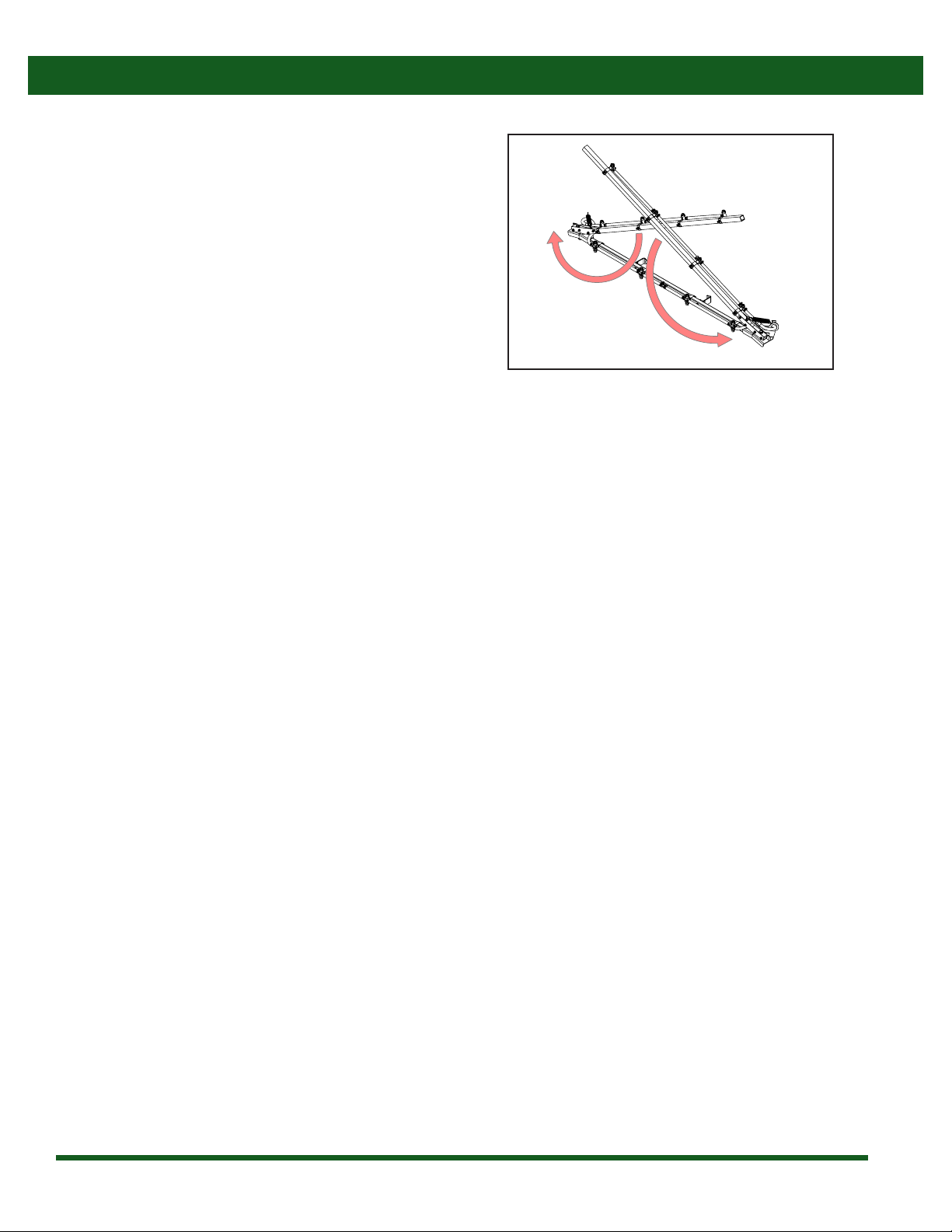

5. Rotate the boom wing towards the center frame to the closed

position.

6. Attach the extension spring (8) (Figure 1 & 5, pg 5 & 6) to the

mounting bracket on the hinge and to the vertical wing bolt

as shown in gure 5 using the washer (12) and acorn nut (7).

7. Install the right boom wing using step 3 through 6.

8. Install nozzle tips onto boom. Insert nozzle tip (16) (Figure 1

& 6, pg 5 & 6) into spray cap (14) (Figure 1 & 6, pg 5 & 6). Then

insert strainer (15) (Figure 1 & 6, pg 5 & 6) into the nozzle body

with the mesh side up. Turn the spray cap onto the nozzle

body. Figure 4: Boom wing mounting

Figure 3: Center frame mounting

ATV-MX240 Assembly Instructions

This ATV-MX240 boom kit requires some assembly. Follow the step-by-step instructions to ensure proper assembly. Before assembling,

make sure that all of the necessary components and parts are present as shown in the tables on page 5.

13

13

11

10

10

9

11

12 7

8

10

11

16

14

15

1

2

*