Croplands Pinto 2000 User manual

Parts & Operator’s Manual

Pinto

Part No. BT-POM00210 - Rev 5

Parts & Operator’s Manual

Pinto

Part No. BT-POM00210 - Rev 5

Pinto BT-POM 1212 - Revision 5

Contents

Foreword

Important Information Section 1

Pre-Operation Section 2

Sprayer Operation Section 3

Sprayer Calibration Section 4

Lubrication & Maintenance Section 5

Trouble Shooting Section 6

Assembly Drawings & Parts Listings Section 7

Pinto BT-POM 1212 - Revision 5

Foreword

AboutThis Manual

Thismanualprovidesassembly,settingup,

operatingandmaintenanceinstructionsfor

the Croplands Pinto sprayer.

Some features explained in this manual

may not be installed on your sprayer.

Please pass on this manual with the

sprayer at the time of resale for usage by

the new owner.

Before Operating

Your Sprayer

1 Before attempting to use your

sprayer, make sure you

read the Operator’s Manual and

properly understand:

• All Safety Issues.

• Assembly & Installation

instructions.

• Calibration of the sprayer.

• Sprayer Operation.

• Sprayer Maintenance.

2 Read and follow instructions on

chemical manufacturers' labels.

3 Always wear applicable protective

clothing.

Read and understand this Operators’Manual before

operating the sprayer.

Terminology

These terms/symbols used throughout

this manual:

• NOTE - to convey useful

operating information.

• CAUTION -to highlight potential

injury or machinery

damage.

• WARNING - to stress potential

dangers and the

importance of

personal safety.

Indicates the strong possiblility of severe

personal injury or damage to machinery if

instructions are not followed.

WARNING

Highlights hazards, unsafe/unwise practices

which could cause injury, damage to property,

machinery or loss of crop yield if instructions

are not followed.

CAUTION

Referstoimportantandusefulinformationwhich

should not be overlooked.

NOTE

Pinto BT-POM 1212 - Revision 5 1.11.1

Section 1

Important Information

Introduction 1.2

General Specifications 1.3

Your Sprayer's Specifications 1.4

Shipping Information & Product ID 1.5

Warranty Policy 1.6

Pre-Delivery Check List 1.7

Warranty Registration 1.9

1.2 Pinto BT-POM 1212 - Revision 5

Important Information

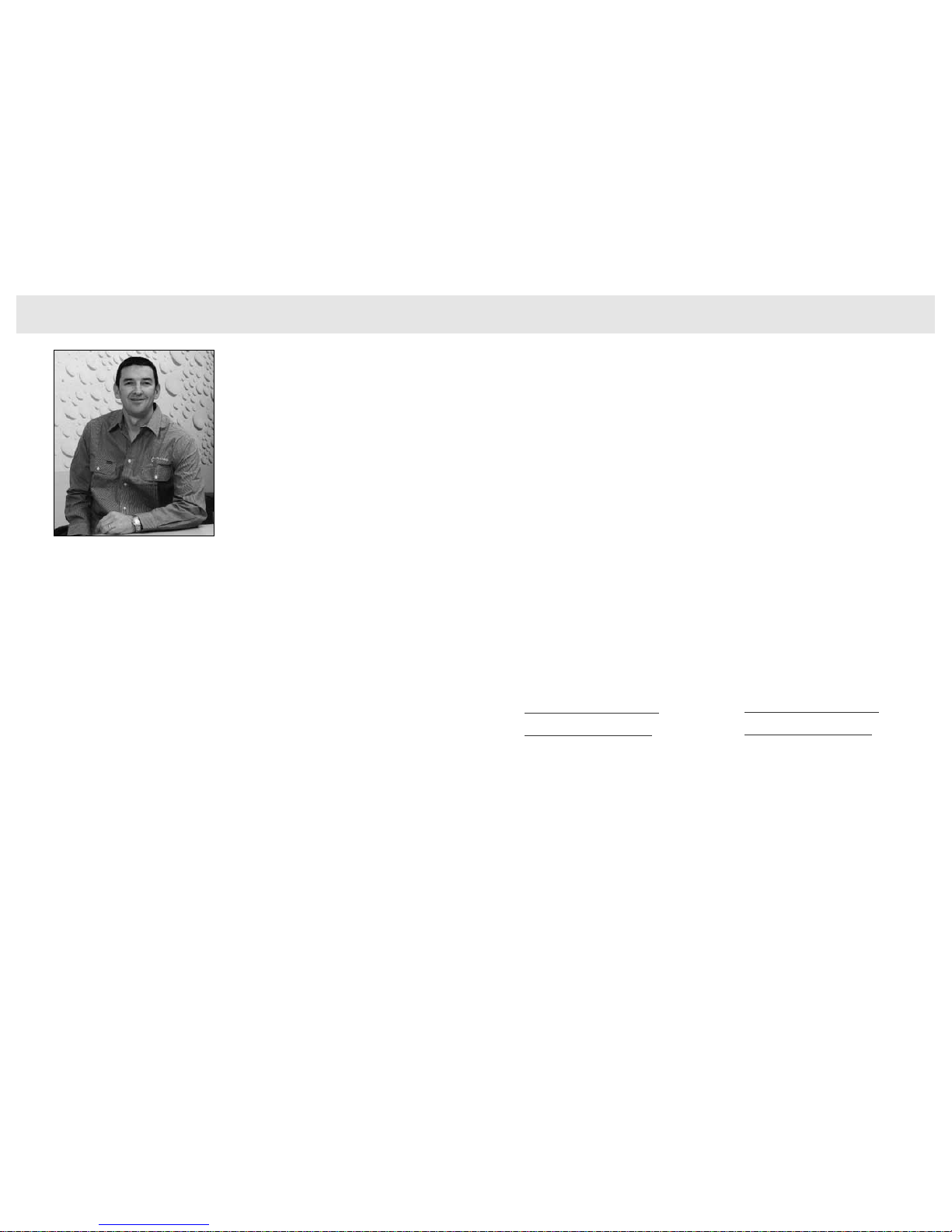

Sean Mulvaney, General Manager of Croplands

Congratulations on the purchase of your

new Croplands sprayer.

Croplands have been in the business of

building and selling spraying equipment

since 1972. For over 40 years we have

been supplying sprayers to farmers,

contractors,growers and all our customers

involvedingrowingcropsandinthecontrol

of pests and diseases.

Croplands is a wholly owned subsidiary

of Nufarm Ltd, the largest supplier of crop

protection chemicals in Australasia, and

oneof the fastestgrowingglobalsuppliers

world-wide.

At Croplands, we pride ourselves on

our commitment to supplying machinery

that is at the forefront of the industry’s

needs. We believe we can back up our

products and through constant research

and development, bring to you the best

equipment you can find.

Wewelcomeany feedbackfromyouabout

our equipment.

Introduction

On this page you will find our contact

details, and locations where our staff can

be reached during business hours.

After hours, you can e-mail us and expect

a reply the following morning.

Please read this manual in its entirety

before you operate your sprayer.This will

ensure you have a trouble-free start up.

In this manual you will find the parts

listings you need should you have any

breakdowns in the future.

Bear in mind that over time, some parts

may become obsolete or be replaced

with better options.You can contact us for

alternative options if this is the case.

We trust you will get years of good use

from your Croplands Sprayer.

Yours sincerely

Sean Mulvaney

General Manager

Contact details:

AUSTRALIA

Croplands Equipment Pty Ltd

ACN 006 450 184

PO Box 2441, Dry Creek

50 Cavan Road, Dry Creek

S.A. 5094

Australia

FreePhone: 1800 999 162

FreeFax: 1800 623 778

e-mail: [email protected]

website: www.croplands.com.au

NEW ZEALAND

Croplands Equipment Ltd

PO Box 2004,

Stotford Lodge, Hastings 4120

Location:

1422 Omahu Road,

Hastings 4120, New Zealand

FreePhone: 0800 106 898

FreeFax: 0800 117 711

e-mail: [email protected]

website: www.croplands.com.au

1.3

Pinto BT-POM 1212 - Revision 5

Section 1

General Description &

Specifications

The new 2000 & 3000 litre Pinto trailed

sprayers feature a new height adjustable

hitch design and new “wide-rail” chassis

for superior strength and ride. The Pinto

provides affordable, practical choices to

meet a wide range of crop and pasture

applications to ensure efficient, high

speed, accurate, safe, easy, economic

and timely spraying operations even in

difficult terrain.

Choosefrom16,18, 21 & 24 metrefully

hydraulicbooms,18 metre manualfolding

suspension boom with hydraulic height

adjustment, single or tandem axle wheel

configuration and many other options.

Electric sprayer controls, integrated

suction probe, 200 litre flushing tank, 30

litrefreshwatertankandfourpointfiltration

provide easy, safe spraying operation.

The Pinto is fitted with a big 160

litre/min, A & R positive displacement

diaphragm pump for trouble free, low

maintenance operation.PTO drive is

standard.

General Specifications

3000 litre Pinto.

Tank

2000 or 3000 litre polyethylene tank with

quick release hinged lid, filling strainer,

top/bottom fill, hydraulic venturi agitation,

antivortex suction, tank drain outlet and

calibrated tank.

Chassis

Strong , solid fabricated, wide rail chassis

designed for maximum durability.

Standard with single wheels (solid axle)

12.4 x 24 for 2000 litre, & 14.9 x 28 for

3000 litre.

Options include tandem Simplicity-style

axle c/with independent suspension

and 15” Landcruiser-style wheels. Other

options are 18.4 x 30 single wheels and

mudguards.

Boom

• 18 metre (60’) manual fold

Torquemaster boom - with

parallellogram suspension & hydraulic

height adjustment. Non-drip, quick

release nozzles.Corrosion and

chemical resistant poly bond finish.

• 16, 18, 21 & 24 metre (50, 60’, 70’&

80’) fully hydraulic boom - stronger

and designed for smoother, more

accurate spraying and long life.

Airbag boom suspension system

protects the boom and improves

the boom ride.

Hydraulic boom lift with easy to

read, 1500mm calibrated height

adjustment.

Adjustable boom breakaways with

90° self returning boom ends.

Boom hydraulically side-folds and

locks for transport. Self levelling

standard.

Protected nozzle bodies and skids

standard.Chemicalandcorrosionresistant

finish.Optionalfencelinenozzle &hydraulic

wing lift with in-cab controls available.

Pump

A & R positive displacement, oil bath

diaphragm pump with chemical resistant

diaphragms.AR160 -160 l/min, maximum

pressure2000kPa(284 psi).Series 4 PTO

drive standard.

Filtration

4 point filtration:

• Basket Strainer 18 mesh

• Suction Filter 50 mesh

• Pressure Line Filter 80 mesh

• Nozzle Filters 100 mesh

Foam Marker (Optional)

1 Salvarani double-sided foam marker

with 20 litre foam tank or RHS 2012

double sided, or

2 RHS 2012 double sided, 20 l/min

foam marker with 55 litre tank and

electrical in cab switch control.

Controller

Electric controls with 3 section boom

control & pressure adjustment standard.

Optional: Automatic sprayer controller for

greater accuracy and chemical savings.

Chemical Handling

Integrated suction probe transports

chemical directly into the tank without

putting chemical through the pump.

Optional: Chem-e-flush 60 litre.

Flushing & Safety

200 litre polyethylene tank with threaded

lid giving large capacity sprayer flushing

facility. 30 litre fresh water tank.

Dimensions (Boom folded)

Model L x W x H

2000 6.5m x 2.9m x 3.0m

3000 6.5m x 2.9m x 3.0m

Approx Weight 1550 kg (2000 litre Dry)

1820 kg (3000 litre Dry)

Machinespecifications are subjectto change withoutprior

notification.

2000 litre Pinto.

1.4 Pinto BT-POM 1212 - Revision 5

Important Information

Your Sprayer's Specifications

Pinto Options:

Tank:

• 2000 ................................................................................ ❑

• 3000 ................................................................................ ❑

Wheels & tyres:

• 12.4 x 24 ...................................................................... ❑

• 14.9 x 28 ...................................................................... ❑

• 18.4 x 30 ...................................................................... ❑

• 12.4 x 42 ...................................................................... ❑

• 15" Tandem on Simplicity Axle ....................... ❑

Boom size:

• 16m Hydraulic ........................................................... ❑

• 18m Hydraulic ........................................................... ❑

• 21m Hydraulic ........................................................... ❑

• 24m Hydraulic ........................................................... ❑

• 18m Manual-fold ...................................................... ❑

Boom sections:

• 3-section ...................................................................... ❑

• 4-section ...................................................................... ❑

• 5-section ...................................................................... ❑

Left/right short-fold kit ................................................. ❑

Left/right wing-lift kit ..................................................... ❑

Triplex Nozzles ................................................................... ❑

Mudguards ........................................................................... ❑

Mud Flaps ............................................................................. ❑

Filling flowmeter .............................................................. ❑

Chem-e-flush c/w drop leg ......................................... ❑

Controller:

• Standard Electric .................................................... ❑

• Automatic Spary-Rate Controller .................. ❑

Foam Marker or Guidance:

• Salvarani Double-sided ....................................... ❑

• R-M2012 20 l/min RHS ....................................... ❑

• RHS Outback 6 ........................................................ ❑

• RHS Outback 10 ..................................................... ❑

• Outback Guidance ................................................. ❑

Fence-line nozzle:

• Manual .......................................................................... ❑

• Electric .......................................................................... ❑

Pump:

• AR135 ........................................................................... ❑

• AR160 ........................................................................... ❑

• Hypro- Centrifugal ................................................. ❑

Pump Drive:

• PTO ................................................................................ ❑

• Hydraulic ..................................................................... ❑

Gooseneck Hitch Assembly:

• c/w Power Pack with Lift only .......................... ❑

• c/w Power Pack with Lift & Fold ..................... ❑

• c/w Power Pack with Lift, Fold & Wing Lift ❑

Electric Brakes .................................................................... ❑

IMPORTANT! Tick the fitted options for your sprayer on this page for future reference.

TickYour Sprayer's Options ( ✔ ) TickYour Sprayer's Options ( ✔ ) TickYour Sprayer's Options ( ✔ )

Your Product Code: ....................................................

Your Serial Number: ...................................................

Spray Rate-Controller Model: .................................

(if fitted)

1.5

Pinto BT-POM 1212 - Revision 5

Section 1 Shipping Information & Product ID

Product

Identification

Always use the serial number of the Pinto

when requesting service information or

when ordering parts.

Early or later models (identification made

by serial number) may use different

parts, or it may be necessary to use a

different procedure for specific service

operations.

Shipping Information

The following shipping information is

provided but variations can occur without

prior notification.

Approx Weight

Model Dry Weight

3000 litre 1820 kg (21m boom)

2000 litre 1150 kg (21m boom)

MaximumTowing Speed

Do not exceed 30 kph when towing on

roads.

Dimensions

Model W x L x H (boom folded)

3000 litre 2.9m x 6.5m x 3.0m (21m boom)

2000 litre 2.9m x 6.5m x 3.0m (21m boom)

(with boom folded)

Pinto Serial Number AR Pump Serial Number

(B)

(A)

Pinto Serial Number Plate

The Pinto Serial Number Plate is located

onthe main frameat the frontof the frame

near the drawbar (A).

This plate shows name of manufacturer,

serial number, product code and date of

manufacture.

Pump Serial Number Plate

The Pump Serial Number Plate is located

on the pump (B).

This plate shows name of manufacturer,

serial number, type of pump, year of

manufacture, maximum flow rate and

maximum working pressure of the pump.

Foam Marker Serial

Number Plate (if fitted)

The serial number provides important

informationabout yourRHS FoamMarker

and may be required to obtain the correct

replacement part(s).

The serial number plate for the marker

is located on the bottom right side of the

enclosure. It is suggested that the serial

number be recorded.

RHS Foam Marker Serial Number (if fitted).

2000 litre Pinto.

3000 litre Pinto.

1.6 Pinto BT-POM 1212 - Revision 5

Important Information

Warranty Policy

Warranty Policy

CroplandsEquipmentPtyLtd(tradingasCroplands)warrantstoitsauthorisedDealer,whointurn,warrantstothe

original purchaser (Owner) that each new Croplands’sprayer, part or accessory will be free from proven defects

in material and workmanship for twelve (12) months from the date of delivery to the first Owner according to the

conditions outlined.This warranty does not cover damages resulting from abuse, accidents, alterations, normal

wear or failure to maintain or use the Croplands product with due care.

During the warrantyperiod, theauthorisedCroplandsDealershallrepair or replace, atCroplandsoption,without

charge for parts and labour any part of the Croplands product, which fails because of defects in material or

workmanship.The Owner must provide the authorised Dealer with prompt written notice of the defect (within 14

days of its occurrence), and allow reasonable time for replacement or repair.Repair may, at Croplands option,

include the replacement of parts with functionally equivalent reconditioned or new parts. Replacement parts will

bewarrantedforthebalanceoftheoriginalwarrantyperiodorforninety(90)days,whicheverislonger.Croplands

(at its option) may request failed parts to be returned to the factory.Any travel time of a service technician and/or

transportation oftheCroplandsproductto theauthorisedservicingDealerforwarrantyworkare theresponsibility

of the Owner.

EXCLUSIVE EFFECT OF WARRANTY AND LIMITATION OF LIABILITY THIS WARRANTY IS IN LIEU OF

ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PURPOSE OR OTHER REPRESENTATIONS,

WARRANTIES OR CONDITIONS, EXPRESSED OR IMPLIED.The remedies of the Owner set forth herein are

exclusive.CROPLANDSneitherassumesnorauthorisesanypersontoassumeforitanyotherobligationorliabilityin

connectionwiththesaleofcoveredmachines.Correctionofdefects,inthemannerandforapplicableperiodoftime

providedabove,shallconstitutefulfillment ofallresponsibilitiesofCROPLANDStotheOwner, andCROPLANDS

shall not be liable for negligence under contract or in any manner with respect to such machines.IN NO EVENT

SHALL THE OWNER BE ENTITLED TO RECOVER FOR INCIDENTAL, SPECIAL OR CONSEQUENTIAL

DAMAGES SUCH AS BUT NOT LIMITEDTO, LOSS OF CROPS, LOSS OF PROFITS OR REVENUE, OTHER

COMMERCIAL LOSSES, INCONVENIENCE OR COST OF RENTAL OR REPLACEMENT EQUIPMENT.

Conditions of Warranty

1. The warranty is not transferable.

2. The Warranty Registration Form must be returned to Croplands by the Owner Operator within 14 days of taking

delivery of the unit. Only when warranty registration is completed and returned, can Croplands fulfill all warranty

obligations.

3. Schedule of components and conditions not covered by warranty are:

Abuse

Environmental Conditions

and Application

NormalWear

Maintenance

Damage

Power Source

Alterations

Removal & Installation

Clean-upTime

Transportation

Costs

DiagnosticTime

Non-Genuine Parts

Unauthorised Repairs

Failure resulting from neglect, such as improper operation, lack of required

maintenance or continued use of a sprayer after the discovery of a defect which

results in greater damage to the unit.

Deteriorated or failed components such as:diaphragms, O-rings, hoses, seals,

electrical wiring and connections damaged by corrosive chemicals, dirt and

sand, excessive heat or moisture.Owners should en sure the type and strength

of chemicals used in the sprayer are compatible with the design of the unit.

Warranty determination for these types of failures will be made by Croplands

only after inspection of failed components.In most instances these will incur

inspection charges and cost of replacement parts.

Normal wear and consumable items such as:oils and lubricants, diaphragms,

filter elements, flowmeters, clutches, fan belts, drive belts, pivot pins, paint,

light bulbs and nozzles are considered to be normal wear items and are not

warranted.

Component failure caused by not performing scheduled maintenance service

such as:oils, grease, failure to clean tanks, pumps, filters, spray lines, nozzles

or any other blocked components.Not tightening or replacing loose or missing

bolts, nuts, fittings, shields and covers.

Damages or machine failure caused by carelessness or accidental damage,

improper operation, excessive speed during travel and operation, inappropriate

transportation or storage of the sprayer or attachment.

Failures due to faulty or inadequate electrical sources of power. Owners who use

their own 12 volt power source must make sure that it is suitable for operating

the spraying equipment.

Any unauthorised alteration, modification, attachments or unauthorised repairs

to the Croplands sprayer or attachments.Written approval must be obtained from

Croplands for any such items to maintain warranty.

The time taken to remove and re-install a warranted part or component into other

brands of sprayers will not be covered by Croplands warranty. Only parts and

labour directly attributable to the repair of the Croplands unit is covered.

Croplands do not pay for cleaning the sprayer, parts, accessories or work area

before or after the warranty repair.Clean-up time is affected primarily by the

application or conditions in which the sprayer is operated and maintained.Since

clean-up time can be so variable, cleaning time should be considered a customer

expense.

Warranty does not cover transportation or insurance costs for sprayers or other

equipment needing repair or re placement of warranted components.Nor does it

cover any freight or insurance costs in obtaining new parts or returning old parts

to Croplands for inspection purposes.

Warranty does not cover time required to diagnose a war ran ty problem.

Diagnostic time is affected greatly by the training and expertise of the technician

employed to do the job.With proper training of service personnel, diagnostic time

should be at a minimum.

Croplands expects that Dealers will assign a well trained and proficient

technician to handle any warranty repairs.Since Croplands is not in control of

either of these responsibilities, we elect not to cover diagnostic time.

Use of parts other than Croplands parts for repair of war rant ed parts will

automatically negate any warranty.Warranted components must be replaced

with genuine Croplands repair parts.

Repairs by an unauthorised agent will automatically forfeit any warranty. An

authorised Croplands Dealer must carry out warranty repairs.

1.7

Pinto BT-POM 1212 - Revision 5

Section 1 Pre-Delivery Check List

1 Operator’s Manuals Supplied:

• Pinto Parts & Operators Manual ................ ❑

• Auto Spray-Rate Controller Manual

(if fitted) ............................................................... ❑

2 Trailer

• Undamaged ...................................................... ❑

• Hitch height adjusted ..................................... ❑

• Hitch Jack lubricated ...................................... ❑

• Axle adjustment bolts tight (if applicable) ❑

• Axle nut adjustment, split pin in place ...... ❑

• Lubricate spring rockers (if applicable)..... ❑

• Check mudguards (if fitted) .......................... ❑

• Check paint ....................................................... ❑

3 Wheels & Hubs:

• Greased ............................................................. ❑

• Bearings adjusted ........................................... ❑

• Split pin and dust caps in place ................. ❑

• Wheel nuts tight & threads greased ......... ❑

• Check tyre pressure ....................................... ❑

4 Tank

• Undamaged ...................................................... ❑

• Agitator adjusted correctly ......................... ❑

• Check main lid opens and seals

shut correctly .................................................... ❑

• Basket strainer in place ................................. ❑

5 Check AllTank Fittings Are Sealed

• Agitators ............................................................. ❑

• Sump outlets ..................................................... ❑

• Tank rinse nozzle ............................................ ❑

6 Boom & Lift Device

• Undamaged ...................................................... ❑

• Check hydraulic height adjustment ........... ❑

• Check boom mounting bolts tight .............. ❑

• Unfold the boom, and .................................... ❑

• Align wing sections .................................. ❑

• Align wing extensions ............................. ❑

• Align balancing device ........................... ❑

• Adjust sliding surfaces ........................... ❑

• Grease the lift .................................................. ❑

• Check nozzle spacings ................................. ❑

• Check nozzle mountings tight .................... ❑

• Check all pins in place .................................. ❑

• Check shock absorber springs (if fitted) .❑

• Lubricate boom hinge points ...................... ❑

• Fold boom to transport position, and

• Check transport cradles ........................ ❑

• Check that hoses are not kinked or

jammed on folding ................................... ❑

7 Power Drive

(a) PTO

• Check quick release pins operate

easily and lock into place ............................. ❑

• Check universal joints work correctly ...... ❑

• Adjust PTO length to suit tractor ............... ❑

• Grease telescopic sliding shaft .................. ❑

• Grease universal joints ................................. ❑

• Check safety shields are in place ............. ❑

(b) Hydraulic Pump Drive & Filling Pump

(if fitted)

• Check pressure & return lines are

identified for Hydraulic pump drive ......... ❑

• Check revs set correctly for hydraulic

pump drive .............................................. ❑

• Check liquid pump operates correctly .... ❑

• Check filling pump operation &

control tap ............................................... ❑

8 Pump

• Check mountings ............................................ ❑

• Check oil level .................................................. ❑

• Check air chamber pressure -

70-100kPa (10-15 psi) .................................. ❑

• Check operation .............................................. ❑

9 Suction Lines

• Undamaged ...................................................... ❑

• Hoses - no kinks or restrictions ................. ❑

• All joins sealed (no air leaks) ...................... ❑

• Filter clean & sealed ...................................... ❑

10 Pressure Lines

• Undamaged ...................................................... ❑

• Hoses - no kinks or restrictions ................. ❑

• All hoses sealed (no leakages) .................. ❑

• Filter clean & sealed ...................................... ❑

11 Bottom-Fill (Spray/Flush Tanks)

• Check bottom-fill operates ........................... ❑

• Filter clean & sealed ...................................... ❑

• Check hoses properly sealed ..................... ❑

• Check caps & plugs in place ...................... ❑

12 Nozzles

• Undamaged ...................................................... ❑

• Nozzle filters clean ......................................... ❑

• Nozzles correct type throughout ............... ❑

• Nozzle caps sealed (no leakages) ........... ❑

• Non-drip diaphragms working .................... ❑

• Check fenceline sprayer operation (if fitted) ❑

13 Agitation

• Check agitator works correctly .................. ❑

• Check hoses are properly sealed ............. ❑

14 Chem-E-Flush (if fitted)

• Check unit is undamaged ............................ ❑

• Check hoses/fittings seal correctly ........... ❑

• Check Chem-E-Flush operation ................ ❑

15 Chemical Probe (if fitted)

• Undamaged ...................................................... ❑

• Check fittings seal correctly ........................ ❑

• Check probe operation ................................. ❑

• Check caps & plugs in place ..................... ❑

16 Electric Controls (Standard)

• Check installation ........................................... ❑

• Check battery connection ............................ ❑

• Fully check controls operation ................... ❑

17 Auto Spray-Rate Controller (if fitted)

• Check installation ........................................... ❑

• Check battery connection ............................ ❑

• Calibrate controller ......................................... ❑

• Fully check controller operation ................. ❑

18 Fresh Water & FlushingTanks

• Undamaged ..................................................... ❑

• Check fittings ................................................... ❑

• Check operation ............................................. ❑

19 Main Control & Drain Valves

• Check there are no leaks ............................ ❑

• Check all valves open & close easily ...... ❑

20 Foam Marker (if fitted)

• Check installation ........................................... ❑

• Check battery connection ............................ ❑

• Check foam tank mountings ....................... ❑

• Hoses - no kinks or restrictions ................. ❑

• All joins sealed (no air leaks) ..................... ❑

• Check filters are clean ................................. ❑

• Check foam marker & in-cab control

operation ........................................................... ❑

21 Gooseneck Option (if fitted)

• Gooseneck correctly fitted to vehicle ...... ❑

• Electric/hydraulic power pack & loom

fitted correctly to vehicle .............................. ❑

• Electric brakes working & adjusted

correctly (if fitted) ............................................ ❑

• Gooseneck complies with State &

Federal Road Laws ....................................... ❑

• Honda pump drive fully operational & oil

level checked ................................................... ❑

22 Decals

• Check all decals are in place ..................... ❑

The Pre-Delivery Check List must be completed by the Dealer & signed by both the Dealer and the Owner, and the white copy returned by the Dealer to Croplands.

✔✔✔✔

Tick each box to affirm completion

DEALER:

Dealership Name: (Print)

.................................................................................

Address: ..................................................................

.................................................................................

.......................................... Postcode: ......................

Signature of Dealer Representative

.................................................................................

Date: .............................

OWNER: Farmer ❑Contractor ❑

Owner's Name: (Print)

.................................................................................

Address: ..................................................................

.................................................................................

.......................................... Postcode: ......................

Phone: .....................................................................

Mobile: .....................................................................

Email: ......................................................................

Signature of Owner

.................................................................................

Date: .............................

Tick each box to affirm completion Tick each box to affirm completion Tick each box to affirm completion

Top Copy (White) - Forward to Croplands; Second Copy (Yellow) - Dealer’s Copy; Third Copy (Blue) - Owner’s Copy.

✔

Tick appropriate box

1.8 Pinto BT-POM 1212 - Revision 5

1.9

Pinto BT-POM 1212 - Revision 5

Section 1 Warranty Registration

Warranty Registration: The Owner acknowledges that the Owner has read & understood all terms & conditions of the Croplands' warranty policy contained in this manual.

The warranty policy will commence upon installation.

This Warranty Registration must be completed & signed by both the Owner & the Dealer, & the white copy returned by the Dealer to Croplands.

IMPORTANT:

By executing this Warranty Registration:

1 The Owner:

(a) Agrees that the Owner will read the Operator’s

Manual before using the Sprayer; will follow all

procedures in the operator’s manual for the

use of the Sprayer, and will exercise due care

in the use of the Sprayer;

(b) Agrees that Croplands' liability for any loss or

damage suffered by the Owner in connection

with the Owner’s use of the Sprayer is limited

to the cost of repair or replacement of the

Sprayer;

(c) Agrees that the Owner will bear any loss the

Owner suffers as a consequence of any

failure by the Owner to comply with 1.1 above;

(d) Acknowledges that the owner is trained and is

fully responsible for the safe and correct

operation of the Sprayer; and

(e) Agrees that the Owner will fully train any

person who might be required to operate the

Sprayer as to how to operate the Sprayer in a

safe and proper manner.

2 The Dealer undertakes that the Dealership has met

the obligations of Sprayer pre-delivery, installation,

service and warranty start up.

ImplementType: ........................................................................

Model: .............................................................................................

Size: .................................................................................................

Product Code: ...........................................................................

Serial No: ......................................................................................

Purchase Date: ...........................................................................

Pre-Delivery Completion Date: ...........................................

Top Copy (White) - Forward to Croplands; Second Copy (Yellow) - Dealer’s Copy; Third Copy (Blue) - Owner’s Copy.

OWNER:

Owner's Name: (Print)

.......................................................................................................

Address: .....................................................................................

.......................................................................................................

............................................................ Postcode: ......................

Phone: .................................... Mobile: ....................................

Email: ..........................................................................................

Signature of Owner:

......................................................................................................

Date: ...............................................

DEALER:

Dealership Name: (Print)

.......................................................................................................

Address: ....................................................................................

........................................................................................................

............................................................ Postcode: ......................

Phone: .................................... Mobile: ....................................

Email: ..........................................................................................

Signature of Dealer Representative:

......................................................................................................

Date: ...............................................

Owner's Machinery Register:(This information will assist us in providing first class back-up and parts service)

1 Type of purchaser (please tick): ❑Owner/Farmer ❑Share Farmer ❑Contractor

2 Major activities (please number in order of importance):

❑ Sheep ❑ Nuts ❑ Nurseries ❑ Vineyards

❑ Beef ❑ Vegetables ❑ Fruit Trees ❑ Council/Govt

❑ Cereal Grain ❑ Flowers ❑ Parks & Lanes ❑ Other

❑ Cotton ❑ Dairy ❑ Sugar Cane ❑ ...............................................

3 What is the size of your holding (hectares)? .....................................

4 What are your reasons for purchasing the Croplands Sprayer? .......................................................................................

.....................................................................................................................................................................................................................

.....................................................................................................................................................................................................................

5 What other Croplands' machinery do you currently use?

Serial No. Implement Type Size Age Comments

.......................... .................................... ................ ................. ............................................................................................

.......................... .................................... ................ ................. ............................................................................................

.......................... .................................... ................ ................. ............................................................................................

.......................... .................................... ................ ................. ............................................................................................

.......................... .................................... ................ ................. ............................................................................................

1.10 Pinto BT-POM 1212 - Revision 5

Pinto BT-POM 1212 - Revision 5 2.1

Section 2

Pre-Operation

Safety 2.2

Hook-up 2.10

Unhitching 2.18

Manual Control Valves

• 3000 Litre 2.19

• 2000 Litre 2.25

Pre-Operation Check

• 3000 Litre 2.20

• 2000 Litre 2.26

2.2 Pinto BT-POM 1212 - Revision 5

Pre-Operation

Safety is the

Operator’s

Responsibility

The Pinto is designed to meet the

most demanding farming conditions,

where large areas, uneven terrain, and

weather-controlled deadlines set the

toughest challenges.

The Pinto is capable of spraying a wide

range of pesticides and fungicides

and the operator must be aware of

the hazards associated with the Pinto

operation.

The dealer explains the capabilities,

application and restrictions of the Pinto.

The dealer demonstrates the safe

operation of the Pinto according to

Croplands instruction material, which

are also available to operator.

The dealer can also identify unsafe

modifications or use of unapproved

attachments.

The following publications provide

information on the safe use and

maintenance of the Pinto and

attachments:

• The Operator’s Manual delivered

with the Pinto gives operating

information, as well as routine

maintenance and service

procedures.It is a part of the

Pinto and must stay with the

machine when it is sold.

• Replacement Operator’s Manuals

can be ordered from your

Croplands dealer, Pinto Part

No. BT-POM 009703.

• The Pinto has machine signs

(decals) which instruct on the

safe operation and care.The

signs and their locations are

shown in he Operator’s Manual.

Replacement signs are available

from your Croplands dealer (as

shown on pages 2.5 - 2.6).

Safe Operation

Needs a Qualified

Operator

A Qualified Operator Must

Do the Following:

1 Understand the

Written Instructions, Rules

& Regulations

• The written instructions from

Croplands are included in the

Pinto Operation & Maintenance

Manual and on machine decals.

• Check the rules and regulations

at your location.The rules may

include any Federal and State

safety requirements for the

chemical applicator.

2 HaveTraining with Actual

Operation

• Operator training must consist of

a demonstration & verbal

instruction.This training is given

by your dealer before the Pinto

is delivered.

• The new operator must start in an

area without bystanders and use

all the controls until they can

operate the Pinto safely all

conditions of the work area.

3 KnowThe Work Conditions

• The operator must know any

prohibited uses or work areas.

They need to know about

excessive slopes and rough

terrain.

• Wear protective clothing as

recommended by the chemical

manufacturer. Always wear safety

goggles when maintaining or

servicing Pinto.

• For an operator to be qualified,

they must not use drugs or

alcoholic drinks which impair

alertness or coordination while

working.

An operator who is taking

prescription drugs must get

medical advice to determine if

they can safely operate a

machine.

Farm Owner

Operations Manager

Machinery

Dealer/Manufacturer

Spray Parts Retailer

Agronomist

Chemical Supplier

Chemical Company

AccreditedTrainer

Spray Operator

Spray Contractor

Safety

There are accredited training programmes for

spray application in each state.We recommend

all operators have accredited training.

NOTE

2.3

Pinto BT-POM 1212 - Revision 5

Section 2 Safety

Rules for Safe Pinto

Operation

• Always read your sprayer operator’s

manual thoroughly before operating.

Accidents occur every year because

of careless use of farm chemicals

and farm machinery.You can avoid

these hazards by observing these

safety instructions.

• Dispose of all chemical containers as

per instructions on label. Failure to

do so could result in contaminating

the environment with chemicals.

• Inspect hose and hose connections

daily. Always wear rubber gloves

when tightening connections.

Damaged, loose or worn hoses could

result in operator being

exposed to toxic chemicals which

could result in serious illness or faulty

sprayer operation.

• Always use the proper application

rate.To assure proper application

rate calibrate sprayer correctly.

The wrong application rate of a

pesticide concentration that is too

high may expose the operator and

the environment to danger.

• Be sure to disconnect the battery

before attempting welding repairs.

• Always wear relatively tight and

belted clothing to avoid entanglement

in moving parts. Failure to do so

could result in serious injury.

• Always stay out from under the

sprayer unless it is resting on the

ground or supported on solid blocks.

Hydraulics or jacks could fail letting

the sprayer fall.This could result in

pinning or crushing of personnel.

• Check the entire sprayer, prior

to each use, for any loose bolts

or mechanical connections.These

precautions can prevent injury to

personnel and damage to equipment.

• Only inflate tyres to rated pressures.

Over inflating causes tyres to burst

resulting in serious injury.

• Use only genuine Croplands parts

for any necessary replacement.

Special alloy steels are used in

many parts which are important to

the equipment design. Home made

parts may look the same but might be

dangerous in operation.

• Follow the chemical manufacturer’s

precautions before cleaning the

sprayer. Exposure to chemicals could

result in serious illness or death.

• Always wear gloves and wash the

machine before doing any

disassembly repair work.Chemical

residues on the machine parts could

contaminate operator or service

personnel causing serious illness.

• Always relieve system pressure

before doing any work on the

machine.Failure to do so could cause

operator to be exposed to high

pressure spray of chemical resulting

in serious injury or machine damage.

• Always be sure all guards are

properly installed on machine before

operating.Failure to do so could

result in entanglement in moving

parts resulting in serious injury to

operator.

• Always keep PTO guard in place

when sprayer is operating.Failure

to do this might result in

entanglement.

• Do not ride on machine when in

motion.This is an unsafe practice

and can lead to serious injury should

the rider fall from the machine.

• Always replace warning decals when

damaged and make certain operator

understands proper safety practices.

• Always stand well clear of sprayer

when operating.The sprayer is

capable of spraying chemicals 20-30

metres from the boom which may be

hazardous to humans.

• Do not disconnect any hoses nozzles

or filters while sprayer is operating.

Disconnecting components while

under pressure will result in

uncontrolled spray discharge which

may be hazardous to humans.

• Always clean the Pinto and

disconnect the battery before doing

any welding repairs. Cover rubber

hoses, and all other flammable parts.

Keep a fire extinguisher near the

Pinto when welding.Have good

ventilation when grinding or welding

painted parts. Wear dust mask when

grinding painted parts.Toxic dust

or gas can be produced.

2.4 Pinto BT-POM 1212 - Revision 5

Pre-Operation

Rules for Safe Use of

Chemicals

• Always read the label before

using chemicals.Follow instructions

from chemical manufacturer on how

to select, use and handle each

chemical. Note protection information

each time before opening the

container.

• Always observe all warnings on

chemical products.Failure to do so

could result in operator or

others being exposed to toxic

chemicals which could result in

serious illness. Remember chemical

manufacturers go to much research

and expense to develop labels for

your protection.

• Be sure you recognise the categories

of toxicity and their key words.

• Verbal warnings must be given if

written warnings cannot be

understood by workers.

• If symptoms of illness occurs during

or shortly after spraying, call a

physician or go to a hospital

immediately.

• Follow label directions and advice

to keep residues on edible portions of

plants within the limits permitted by

law.

• Keep chemicals out of the reach

of children, pets and unauthorised

personnel. Store them outside of the

home, away from food and feed and

lock them in a secure area.

• Keep bystanders away from spray

drift.

• Always store chemicals in original

containers and keep them tightly

closed. Never keep them in anything

but the original containers.

Read labels for hazards about

chemical reaction with certain types

of metals.

• Do not spill chemicals on skin

or clothing. If chemicals are spilled,

remove contaminated clothing

immediately and wash skin (and

clothing) thoroughly with soap and

water.

Wash hands and face with soap

and water and change clothing after

spraying. Wash clothing each day

before reuse.

• The main tank and system should be

emptied of chemical mixture

and flushed with clean water before

servicing the spray system

or spraying components.Clean the

Pinto of all chemical residue before

servicing.

• Avoid inhaling chemicals.When

directed on the label, wear protective

clothing, face shield or goggles.

• Never smoke while spraying or

handling chemicals.

• Cover food and water containers

when spraying around livestock or pet

areas.

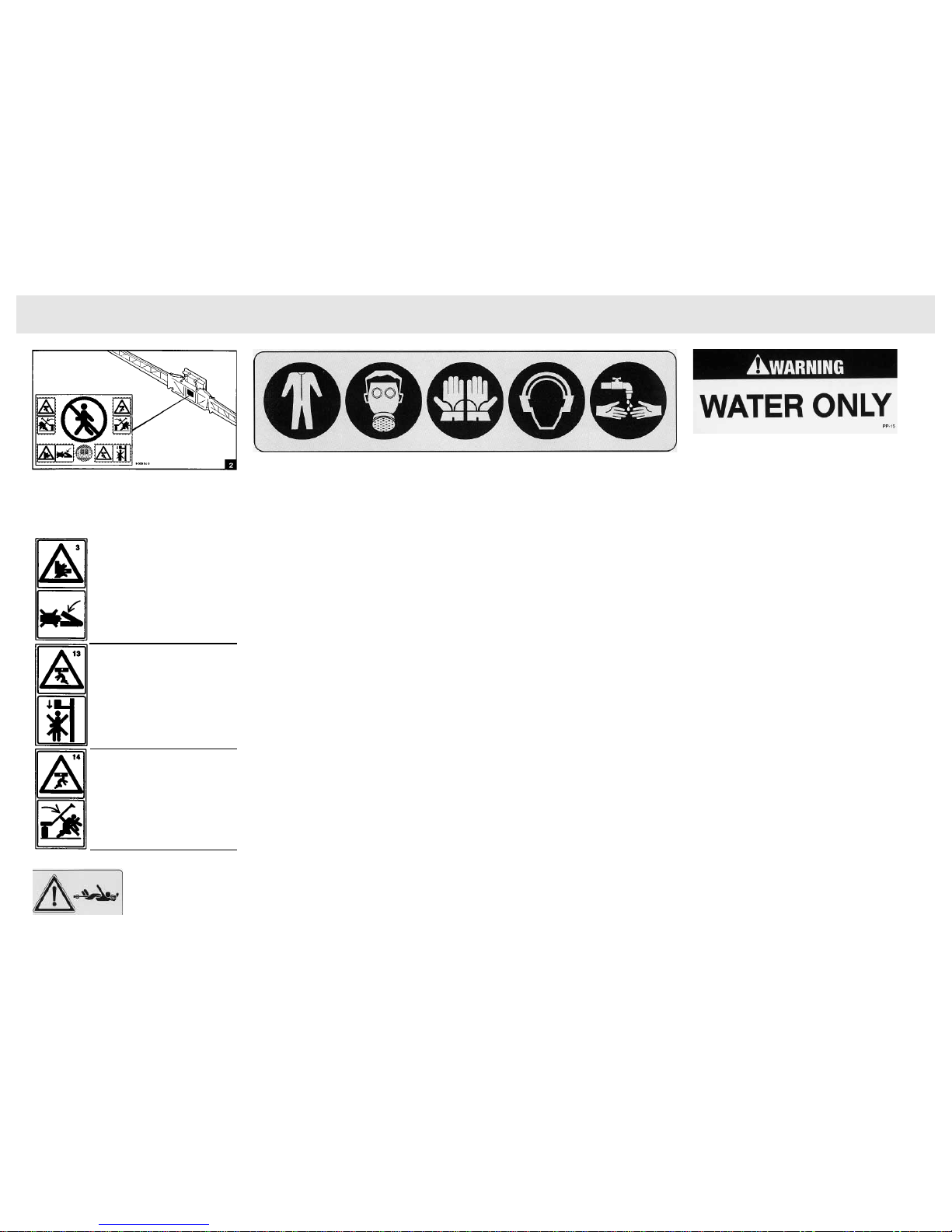

Make sure all boom safety decals are

clear and in place. Replace them if

damaged

Danger of arms crushing.

This area must be kept clear

during equipment operation.

Danger of body crushing.

This area must be kept clear

during equipment operation.

Danger of body crushing.

This area must be kept clear

during equipment operation.

do not stand within range of

boom arms

Danger of PTO

entanglement.

This is a common injury in

farming.Ensure PTO cov-

ers are always in place.

Safety

2.5

Pinto BT-POM 1212 - Revision 5

Section 2 Safety

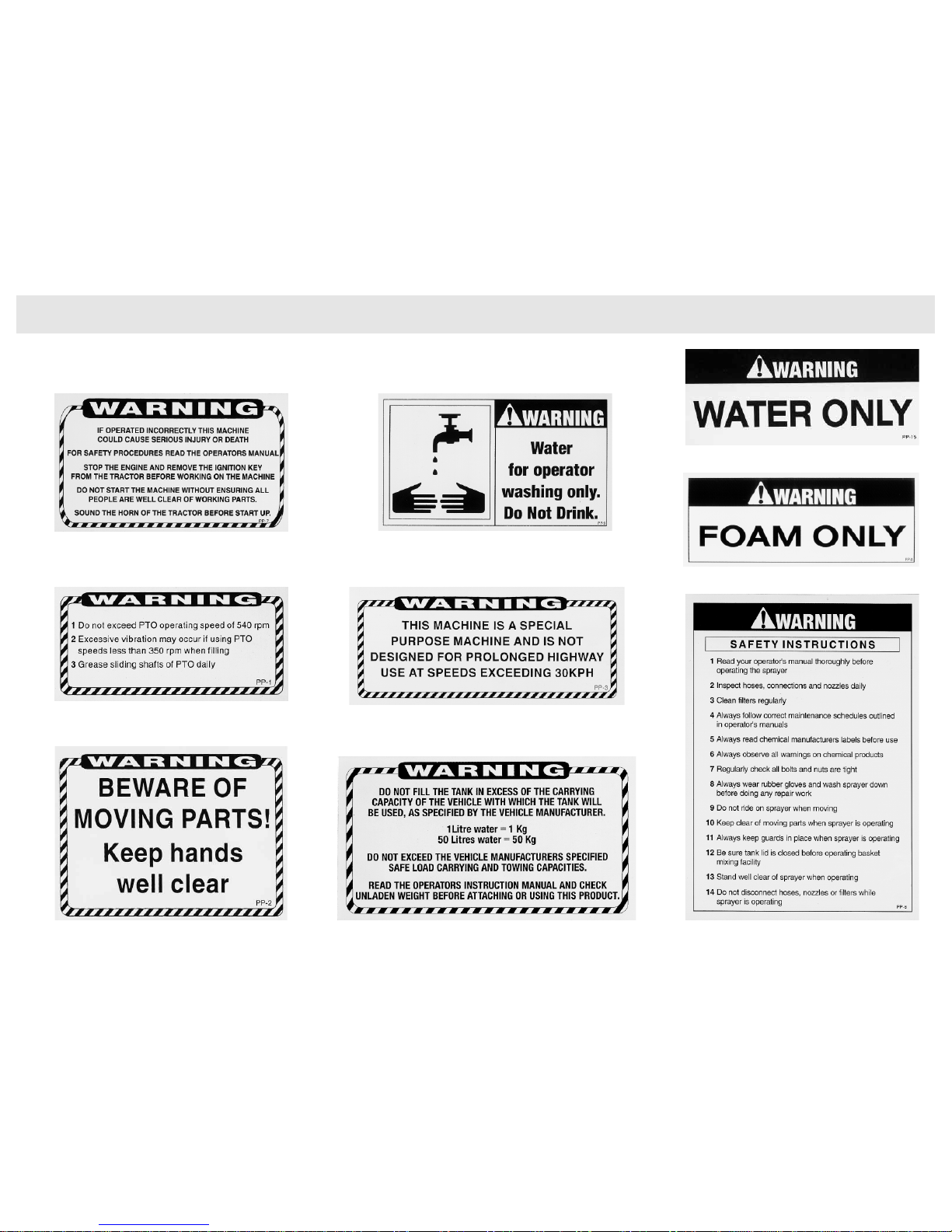

Please order replacements if required

Decals -

2.6 Pinto BT-POM 1212 - Revision 5

Pre-OperationSafety

Please order replacements if required

Decals -

2.7

Pinto BT-POM 1212 - Revision 5

Section 2 Safety

Safety must be an Integral Part of

Chemical Farming Operations

• Not Just an AfterThought!

The Hazard

Allagricultural chemicals or pesticides,as

theyarecommonly called, are biologically

active. When handled incorrectly or

carelessly, they can be dangerous to all

living organisms such as humans, birds,

fish, bees, domestic animals and plants.

Method of Pesticide Entry

☞Oral - Direct by drinking,

splashing into mouth,eating

and smoking with contaminated

hands, eating sprayed produce,

cleaning nozzles with mouth.

☞Inhalation - Nose, mouth, but

predominately the lungs.

☞Dermal - Absorption through the

skin. Increased when skin is

broken or perspiring.

☞What protective clothing and

equipment is needed?

☞Know the correct first aid/safety in

case of poisoning.

☞Seek medical advice if health is

affected by chemicals.

Mixing the Product

☞Reduce or eliminate operator

contact by using closed loading

systems, auto fillers, wettable

powder mixtures or wettable

dispersable granules.

☞Use the right protective clothing

when handling the concentrate.

The user is at greatest risk when

handling chemical in concentrate

form.

☞Open bags carefully. Cut to open,

do not tear.

☞Do not stir chemicals with hands

orarms.

☞Choose the mixing site carefully &

the fate of the probable residues.

☞Do not mix more spray solution

than is needed and avoid

needless disposal of unwanted

chemicals.

Rate of Absorption

While pesticides are absorbed more

completely orally and by inhalation,

greater exposure and more poisonings

occur through skin (dermal) contact.

Hazard and Chance of

Poisoning

The hazard and chance of poisoning is

much higher when handling pesticides in

concentrate form than in the dilute form.

Safe Handling

Know your Pesticides:

☞STOP!! Read the label

☞Is it the right pesticide?

☞What is its poisons schedule or

toxicity?

☞What safety precautions are

required?

☞What is its persistence and

withholding period?

☞What is its mode of action?

☞Will it be a hazard to neighbouring

crops and people?

Plan your Spray Route

☞Observe weather conditions,

especially wind direction & speed.

☞Try to travel across wind and into

untreated crop.

☞Prevent double or over spraying.

☞Prevent or minimise drift onto

other crops, workers, etc.

Disposal of Unwanted

Pesticides and Containers

☞Calibrate correctly to ensure you

do not have a large quantity of

unwanted spray left over.

☞Rinse empty containers and pour

residue into the main tank.

☞Dispose of containers in the

correct manner and where

provided, use pesticide drum

disposal schemes.

This manual suits for next models

1

Table of contents

Other Croplands Paint Sprayer manuals

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual

Croplands

Croplands Quantum Mist Smart Spray QM-420 User manual

Croplands

Croplands RSRL3-100RC REEL User manual

Croplands

Croplands WEED-IT User manual

Croplands

Croplands GEX Series User manual

Croplands

Croplands CROPPAK US200F User manual

Croplands

Croplands PEGASUS WEED-IT 4000 User manual

Croplands

Croplands AgriPak LA300 User manual

Croplands

Croplands MHL12 User manual