WDT Operating Instructions GRANUDOS 45/100 (S3 - 04/02) Page 7 of 7

_______________________________________________________________________________

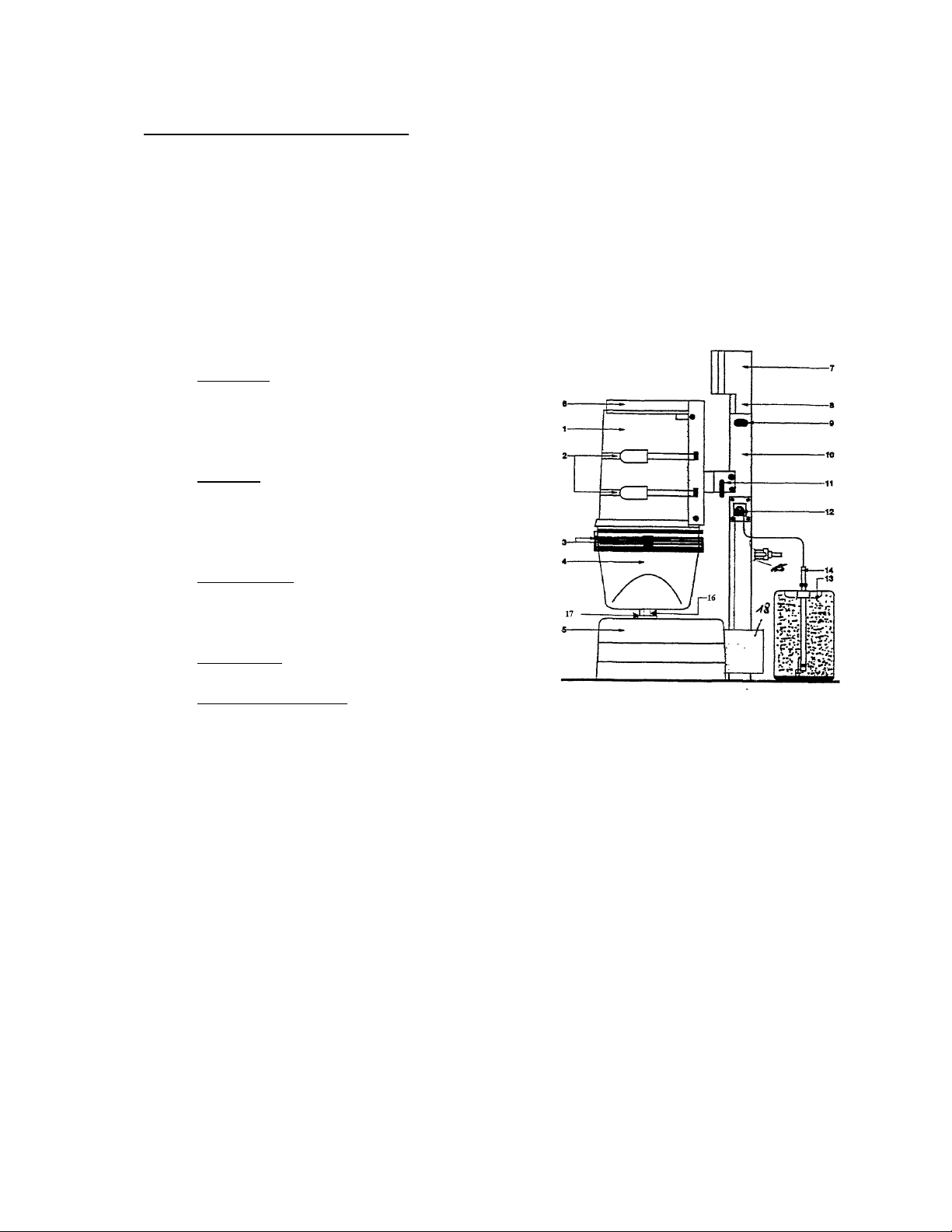

4 red lamps to indicate faults: acid empty, suction venturi low, water level in tank low

(indicated too, if pressure switch is fitted and indicating), water level in tank high,

dosing is stopped in these cases.

1 red lamp to indicate chlorine empty – dosing is not stopped.

Inside on control plate:

1 primary fuse 1,25 amp slow

1 secundary fuse 315 mA slow for all outputs

dosing motors, switches, relays

The function of the booster pump is not influenced by any fault, only dosing is stopped.

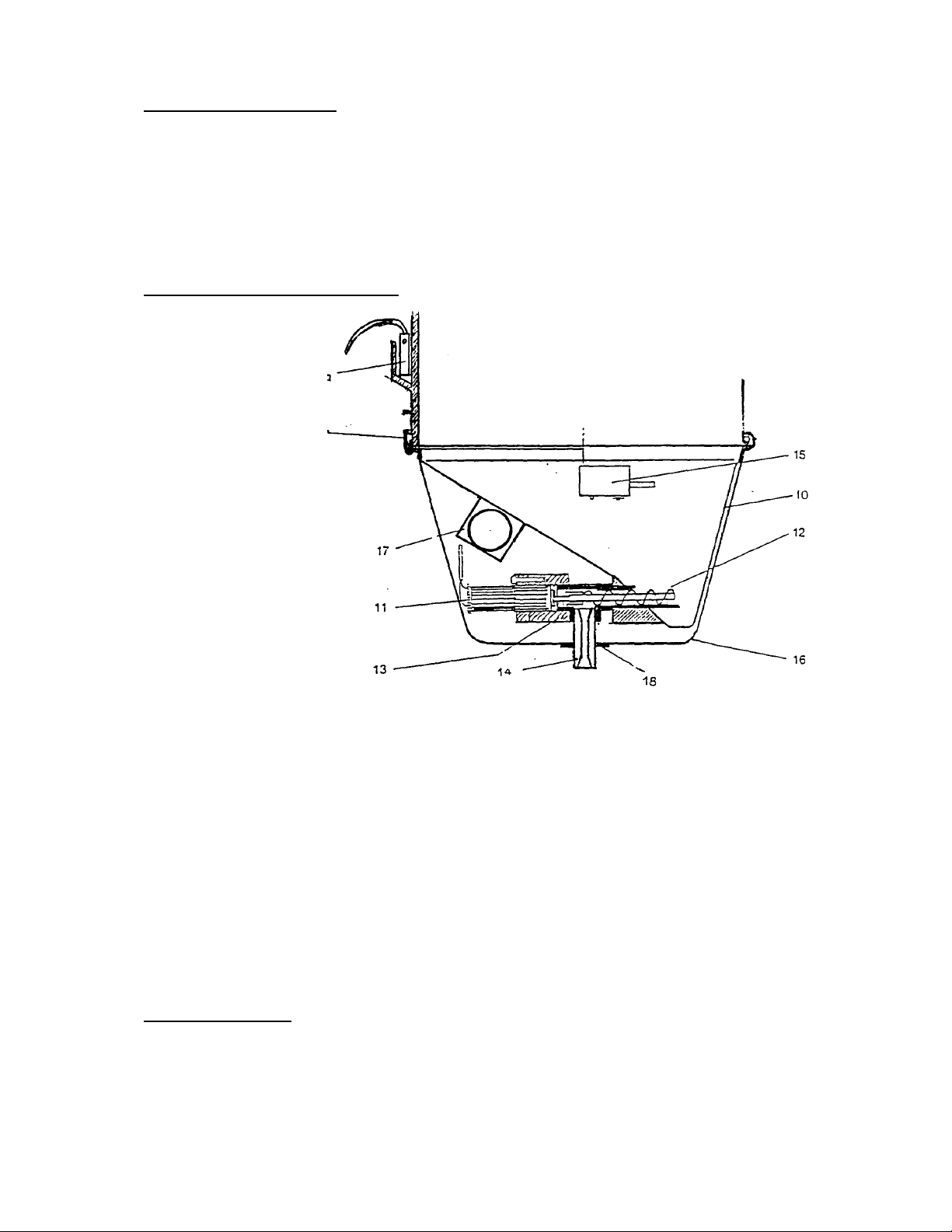

1.6.2 Dosing control system

The dosing performance is set by setting a dosing cycle time (1 – 8 minutes) valid for both chemicals and

a dosing time for each chemical separately (0 – 20 seconds). At continuous dosing all cycle dosing of

chlorine and acid is running as set.

Maximum dosing is got with a cycle of 1 minute and dosing times 100 %, actually: 20 sec dosing acid,

10 sec. pause, …20 sec. dosing chlorine, 10 sec. pause

At setting a longer cycle time, the pause in between the dosings of chlorine and acid are becoming

accordingly longer.

At connecting an external auto controller for free chlorine and pH this dosing cycle is activated, too.

Dosing is running if external control output meets the internal “ability”. To get a sufficient dosing

performance the controller cycle should be in the range of some minutes and the dosing control at the

GRANUDOS should be set to maximum. The auto controller input must be 230 VAC on/off.

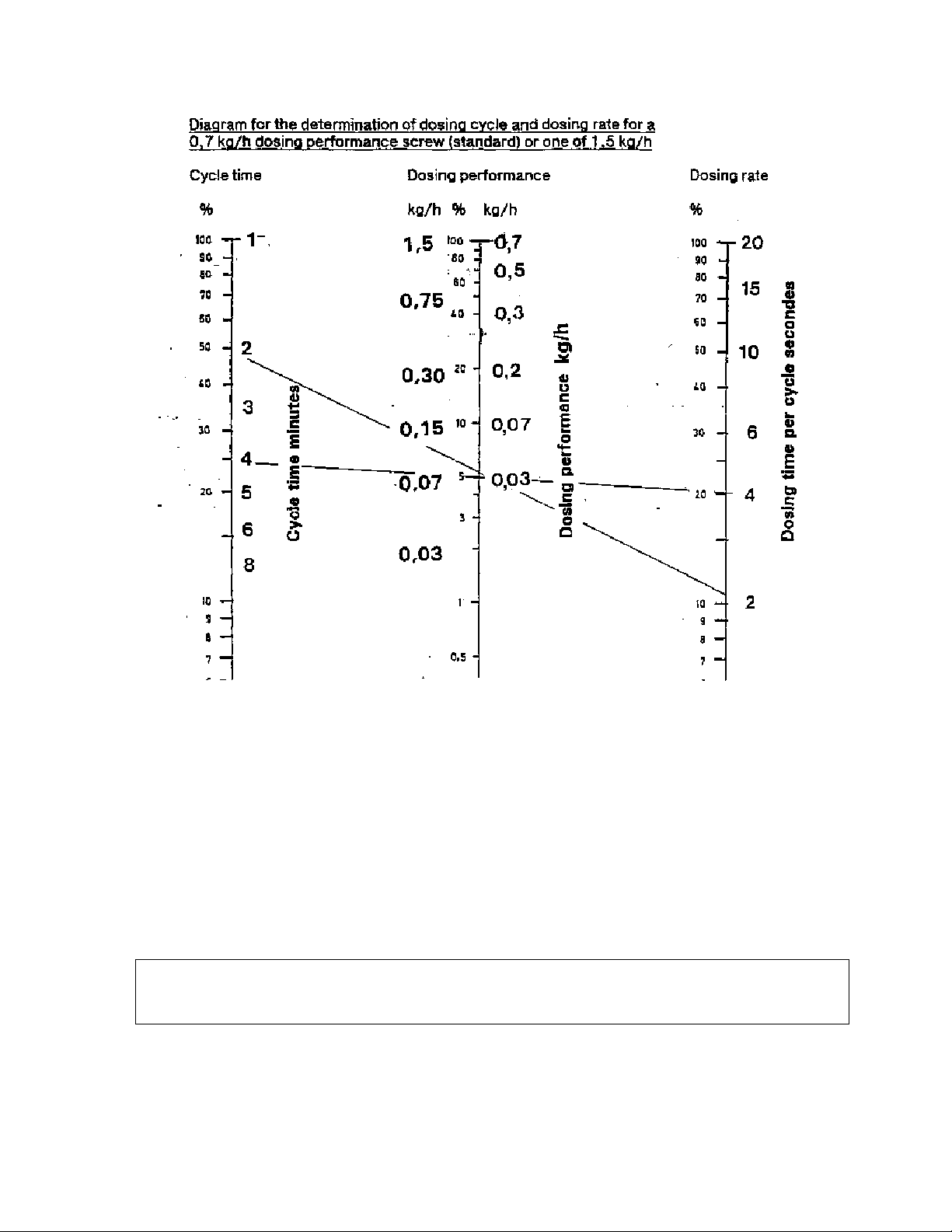

1.6.3 Dosing Performance Adjustment – see diagram next page

1. Chlorine

In principle the chlorine consumption of a pool depends on a variety of influences:

Loading, temperature, wanted chlorine concentration etc. Normally a standard indoor pool

needs about 300 g of calcium hypochlorite per 100 m

3

in volume per day. So a pool of 300

m

3

in volume needs app. 900 g/day or app. 37 g/h at continuous dosing. These 37 g/h

corresponds to 5 % of the maximum dosing performance of 0,7 kg/h. This is achieved with

a cycle time of 2 minutes and a corresponding dosing rate of 10 %. The same dosing

performance is achieved with a cycle time of 4 minutes and a dosing rate of 20 %. See

performance table next page.

An outdoor pool needs at good whether conditions about 3-5 times more chemical

2. Acid

The consumption of acid is harder to predict as that of chlorine. For the beginning set a

dosing performance of same as for chlorine. The actual need has to be found by trial and

error. The pH should be at 7,0 – 7,4.

1.6.4 Dosing Controlled by Auto-Controller