6

The proven mc-22s is now being produced in a new

version under the designation mc-22s, featuring a

PLL Synthesizer RF module as standard. The hard-

ware has also been modified in several respects. For

example, “non-volatile memory” is now used to store

model data, eliminating the need for a Lithium back-

up battery if the main battery should be discharged.

The software has also been expanded by the intro-

duction of a language select facility: the entire menu

system can now be switched at any time to German,

English, French or Italian at will, without requiring any

changes to the programming.

An optional DSC module is now available under Or-

der No. 3290.24. When fitted with this module the mc-

22s transmitter is ideally equipped for use as the con-

trol unit with flight simulators; it can also be connec-

ted directly to a receiver using a DSC lead (see Ap-

pendix). The direct connection is useful for set-up and

testing, as servo signals are transferred to the recei-

ver without the transmission of an RF signal.

The many advantages of the previous mc-22 have

made the system extremely popular, with many thou-

sands of sets already in use, and – as you would ex-

pect – these outstanding features are retained in full

in the new version.

In conjunction with the “DS 24 FM S” mini dual-

conversion receiver, the transmitter can control up

to twelve servos individually. This means that it is

straightforward to use two or more servos on the rud-

der or elevators for the more extreme models.

Fitting the well-known NAUTIC modules provides ad-

ditional expanded functions, which means that fans of

scale model boats and multi-function ships can also

exploit the advantages of the mc-22s.

If used with the new “smc”-series receivers, the mc-

22s can provide servo travel at extremely high reso-

lution with 1024 control increments, ensuring super-

fine control using the SUPER-PCM digital modulation

mode. Naturally we guarantee full compatibility with

earlier PPM / FM receiver systems.

The mc-22s and its software are designed to hand-

le the widely varying requirements of the modern mo-

deller, as well as the more demanding programming

required by the advanced and competition flyer. The

hardware incorporates all the latest developments,

and is laid out in such a way that it can easily exploit

future software development, which continues all the

time.

Operating the transmitter’s software could hardly be

simpler: a digital rotary control and just four “softkeys”

make model programming speedy and direct.

The beginner in particular will certainly appreciate the

carefully designed lay-out of the menus and screen,

conceived with clarity in mind. However, if you en-

counter a problem and the manual is not immediately

to hand, a quick button-press calls up the integral “on-

line help” which will quickly get you back up to speed.

It is important for the beginner’s first attempts at pro-

gramming the transmitter to be as painless as possib-

le, and with this in mind our developers decided to re-

strict the menus available initially to just the basic pro-

gramming essentials. Of course, you can activate all

the facilities of the suppressed menus at any time if

you wish; alternatively you can set the mc-22s trans-

mitter to work in “Expert” (unrestricted) mode from the

outset.

The software is carefully arranged in a neatly structu-

red menu system. Options which are inter-connected

in terms of function are clearly organised by content,

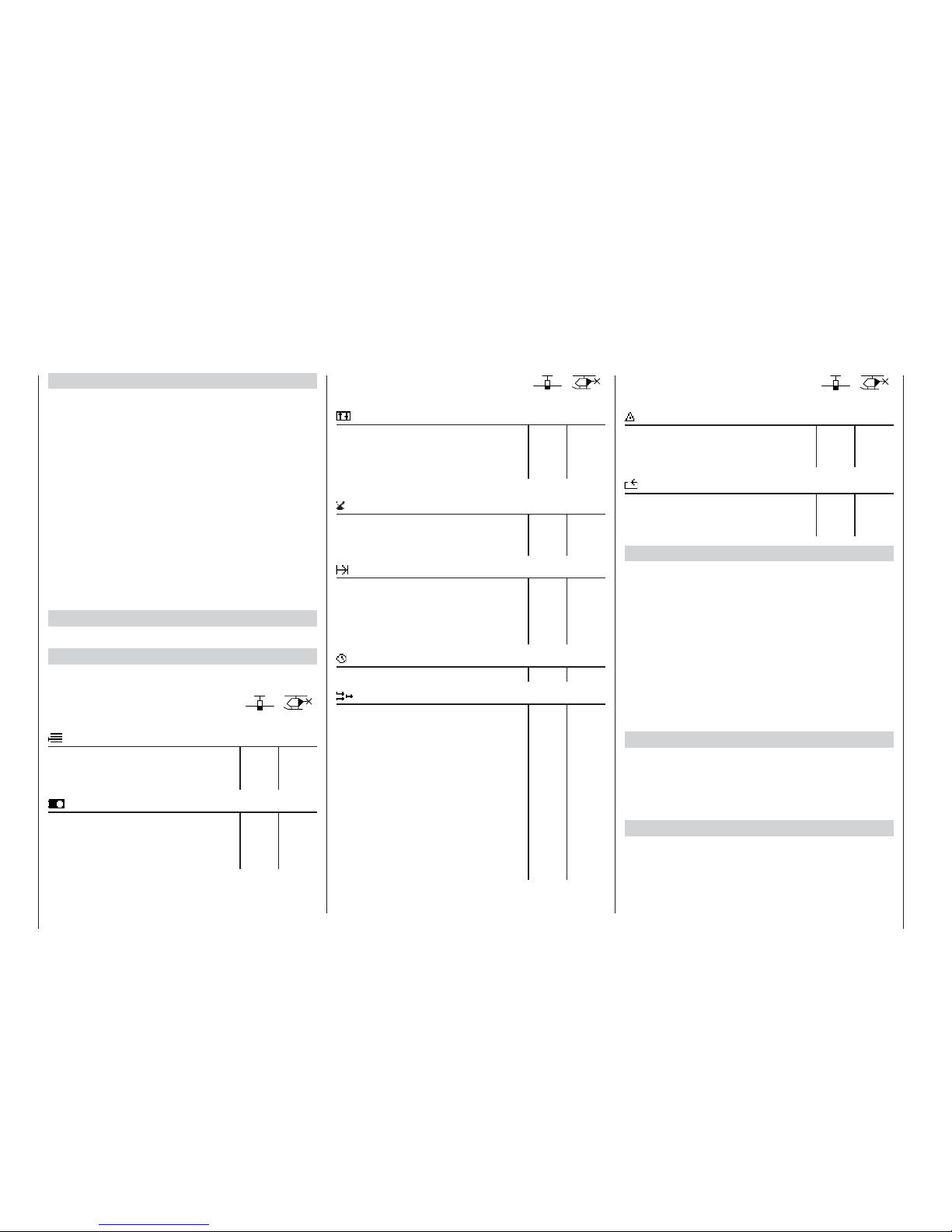

and are symbolised by the following pictograms:

Memory

Basic settings: transmitter, servos, model

Transmitter control settings

Switches

Flight phases

Timers

mc-22s – a new generation of radio control technology

Introduction

Mixers

Special functions

Global functions

The mc-22s provides thirty model memories, each

of which can store model settings for up to four flight

phases. Flight phases can be called up in flight simply

by operating a switch, so that you can try out different

settings quickly and without risk.

The large graphic screen provides a clear display of

all functions, making the transmitter very easy to use.

The settings of the various mixers, Dual-Rate / Expo-

nential and the Channel 1 curve can all be display-

ed in graphic form, and this is extraordinarily helpful

when setting up non-linear curve characteristics.

This manual describes each menu in detail, and also

provides dozens of useful tips, notes and program-

ming examples to complement the basic informati-

on. More general modelling terms, such as transmit-

ter controls, Dual Rates, butterfly and many others,

are all explained in the manual, which also includes a

comprehensive index at the end. You will find a quick-

access tabular summary of the essential operating

procedures on pages 38 to 44.

Please read the Safety Notes and the technical infor-

mation. We recommend that you start by checking all

the functions as described in the instructions. When

you have programmed a model, it is important to

check all the programmed settings on the ground be-

fore committing the model to the air. Always handle

your radio-controlled model with a responsible attitu-

de to avoid endangering yourself and others.

We in the GRAUPNER team offer our grateful thanks

to all the many modellers who have helped us deve-

lop this system by passing on constructive suggesti-

ons, valuable tips and programming examples, and in

so doing have helped us design and produce this ver-

sion of the system and its operating manual.

Kirchheim-Teck, January 2007