GRAUPNER GmbH & Co. KG D-73230 KIRCHHEIM/TECK GERMANY

Modifications reserved. No liability for printing errors 12.2010

2

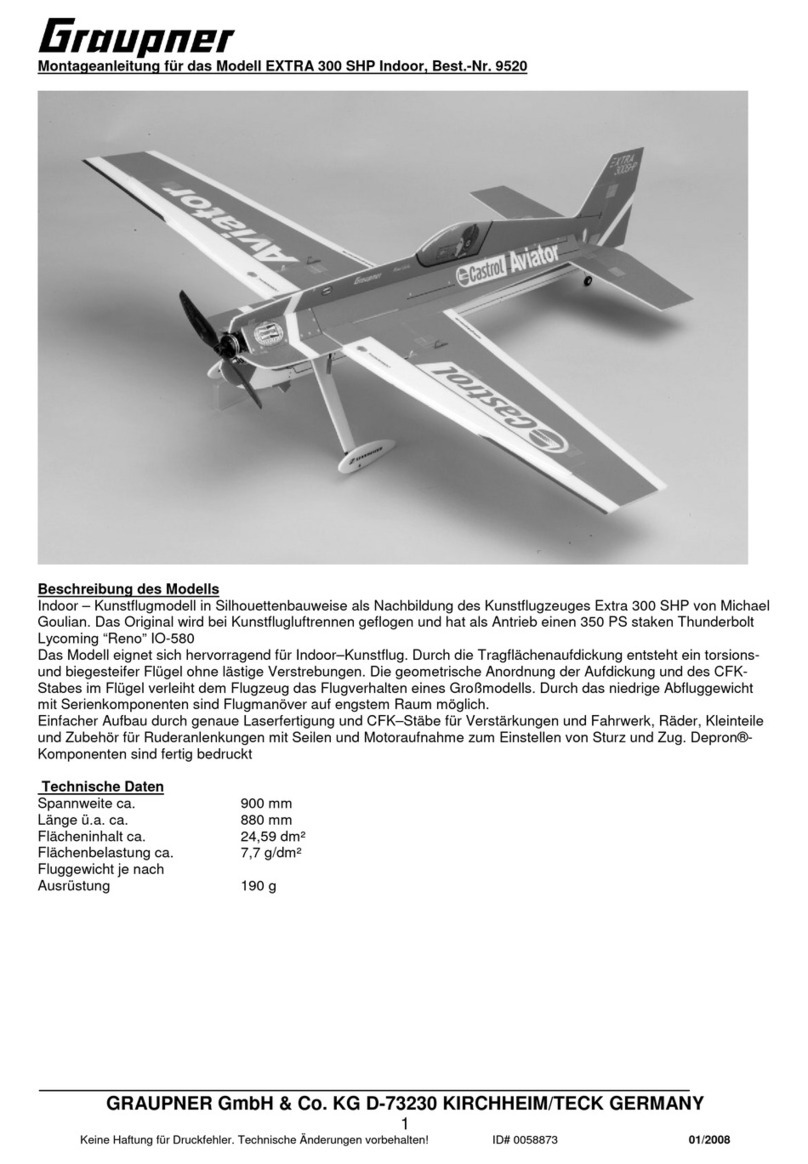

Specification

Wingspan approx. 2000 mm

Overall length approx. 1115 mm

Wing section NACA 4409

Tailplane section l Clark Y

Wing area approx. 62.47

Tailplane area approx. 7.5

Total surface area approx. 69.97

All-up weight according to

fittings, min. approx. 1110 g

Longitudinal dihedral approx. 1.5°- 2°

Centre of Gravity approx. 110 mm aft of the root leading edge,

measured on both sides of the fuselage

Notes on building the model

It is essential to read right through these instructions before starting to build the

model. Please be aware of the hazards involved in the use of tools.

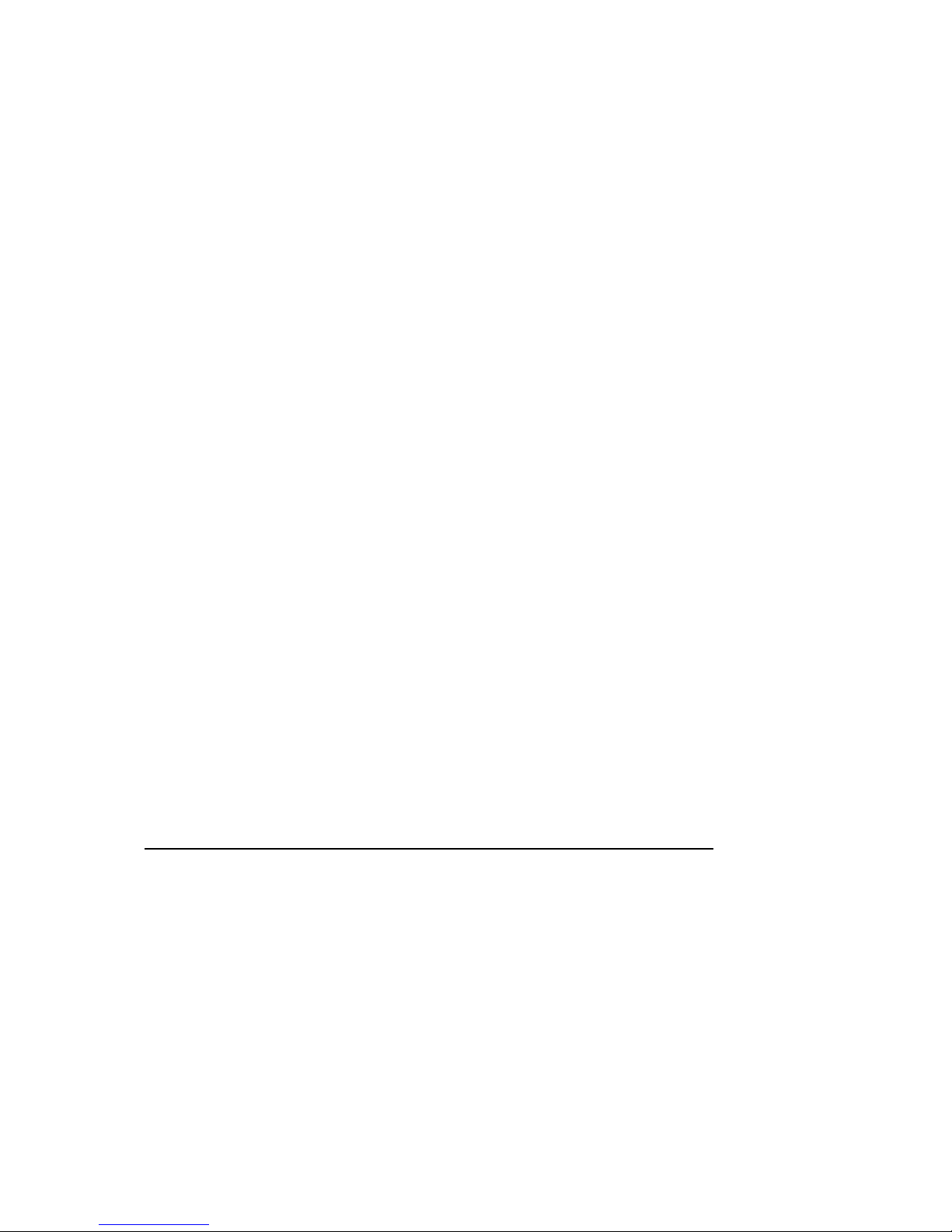

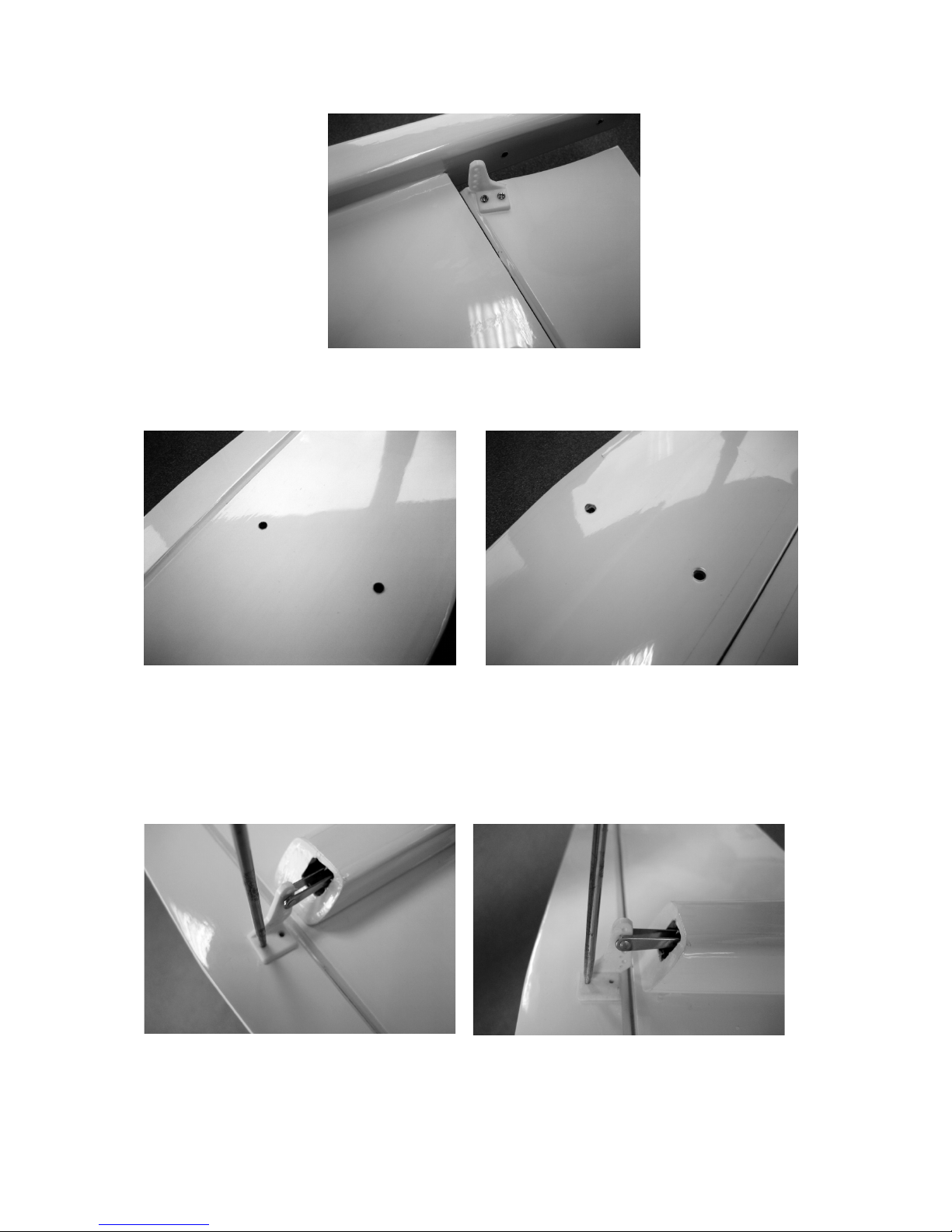

Remove all traces of grease from the joint surfaces of components which are to be

glued. A good method is to sand lightly before wiping with a non-greasy liquid deter-

gent solution. Before gluing any GRP parts, and GRP fuselages in particular, the joint

surfaces must be sanded thoroughly with fine-grit abrasive paper before de-greasing

with a solvent such as acetone. This is the only method of obtaining durable glued

joints involving GRP parts.

Tools required to build the AMIGO IV

Pencil (HB lead), felt-tip pen, setsquare, tape measure or metre rule, Lexan shears,

Order No. 26, sharp, narrow-bladed knife, e.g. balsa knife, Order No. 980, small

electric drill, set of twist drills.

Gluing different materials

The following table provides a few examples of typical glued joints.

It is just a guide, and is not intended to be comprehensive.

Material Typical glued joint Adhesive

Order No.

Wood to Fin to UHU wood glue express

wood fuselage 958.60

or

UHU hart

534.35

Note:

Please observe the instructions provided by the adhesive manufacturers when using

their products. For more information on adhesives refer to the main FS catalogue.

Solvent-based adhesives should always be used in a well ventilated room.

Observe the manufacturer’s instructions and warnings.