TABLE OF CONTENTS

Declaration of Conformity.................................................................................................................. i

Introduction......................................................................................................................................ii

List of Revisions ..............................................................................................................................iii

Model and Serial Number.................................................................................................................iv

1 Safety.................................................................................................................................................... 1

1.1 Safety Alert Symbols........................................................................................................................ 1

1.2 Signal Words................................................................................................................................... 2

1.3 General Safety ................................................................................................................................ 3

1.4 Maintenance Safety......................................................................................................................... 6

1.5 Hydraulic Safety .............................................................................................................................. 7

1.6 Tire Safety....................................................................................................................................... 8

1.7 Safety Signs.................................................................................................................................... 9

1.7.1 Installing Safety Decals ............................................................................................................ 9

1.8 Safety Decal Locations .................................................................................................................. 10

1.9 Interpreting Safety Signs................................................................................................................ 17

2 Reference............................................................................................................................................ 25

2.1 Definitions..................................................................................................................................... 25

2.2 Component Identification................................................................................................................ 27

3 Specifications ..................................................................................................................................... 29

4 Operation ............................................................................................................................................ 33

4.1 Owner/Operator Responsibilities..................................................................................................... 33

4.2 Operational Safety......................................................................................................................... 34

4.2.1 Header Safety Props.............................................................................................................. 34

4.2.2 Reel Safety Props.................................................................................................................. 35

Engaging Reel Safety Props............................................................................................ 35

Disengaging Reel Safety Props ....................................................................................... 36

4.2.3 Endshields............................................................................................................................. 37

Opening Endshields........................................................................................................ 37

Closing Endshields ......................................................................................................... 38

Removing Endshields ..................................................................................................... 39

Installing Endshields ....................................................................................................... 40

Adjusting Endshields....................................................................................................... 41

4.2.4 Daily Start-Up Check.............................................................................................................. 42

4.3 Break-in Period.............................................................................................................................. 43

4.4 Shutdown Procedure ..................................................................................................................... 44

4.5 Cab Controls................................................................................................................................. 45

4.6 Header Setup................................................................................................................................ 46

4.6.1 Header Attachments............................................................................................................... 46

4.6.2 Header Settings..................................................................................................................... 46

4.6.3 Reel Settings ......................................................................................................................... 48

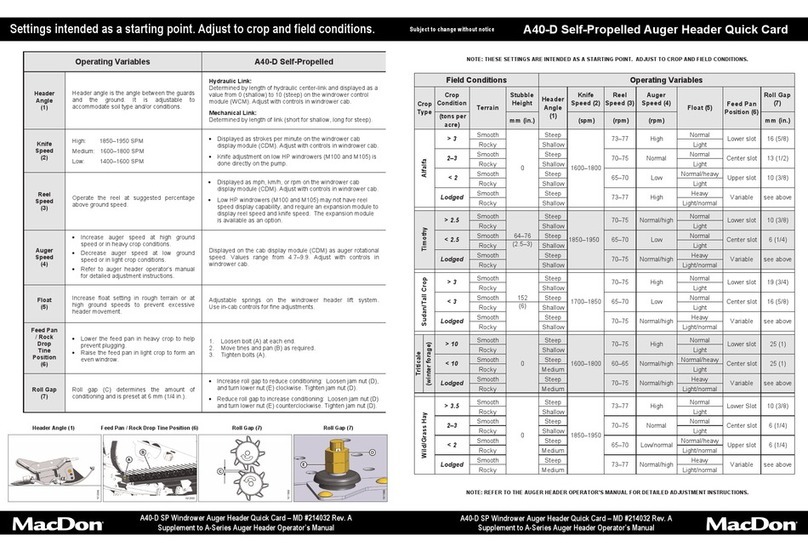

4.7 Header Operating Variables ........................................................................................................... 50

4.7.1 Cutting Height........................................................................................................................ 50

Cutting Off The Ground................................................................................................... 50

Cutting On the Ground.................................................................................................... 53

4.7.2 Header Float.......................................................................................................................... 55

4.7.3 Header Angle......................................................................................................................... 55

Controlling Header Angle ................................................................................................ 56

4.7.4 Reel Speed............................................................................................................................ 56

Optional Reel Drive Sprockets......................................................................................... 56

4.7.5 Ground Speed ....................................................................................................................... 57

4.7.6 Draper Speed ........................................................................................................................ 57

4.7.7 Knife Speed........................................................................................................................... 58

4.7.8 Reel Height............................................................................................................................ 58

169899 vRevision A