Contents

PART I INSTALLATION..............................................................................................................................1

1. SYSTEMOVERVIEW..................................................................................................................... 1

2.ASSEMBLYINTRODUCTION........................................................................................................ 2

2.1ASSEMBLYLIST............................................................................................................................ 2

2.1.1 SAFETY REQUIREMENT FOR ENGINEERING INSTALLATION CONSTRUCTION .... 2

2.2 GATEWAY ME30-24/D4(B)........................................................................................................... 2

2.2.1 FUNCTION INTRODUCTION................................................................................................... 2

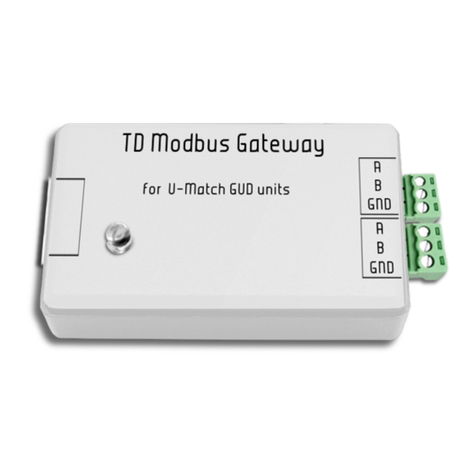

2.2.2 APPEARANCE PICTURE......................................................................................................... 3

2.2.3 ASSEMBLY.................................................................................................................................. 3

2.2.4 INTERFACE ................................................................................................................................ 4

3.EQUIPMENT INSTALLATION......................................................................................................... 5

3.1 PRODUCT SIZEAND SPATIALSIZE FOR ELECTRIC CONTROLCABINET

INSTALLATION..................................................................................................................................... 5

3.1.1 PRODUCT SIZE......................................................................................................................... 5

3.1.2 SPATIAL SIZE FOR ELECTRIC CONTROL CABINET INSTALLATION........................... 5

3.2 COMMUNICATION CONNECTION ............................................................................................ 6

3.2.1 MATERIAL SELECTION FOR COMMUNICATION LINE..................................................... 6

3.2.2 COMMUNICATION CONNECTION METHOD ...................................................................... 6

3.2.3 COMMUNICATION CONNECTION STEP............................................................................. 7

PART II DEBUG OPERATION.................................................................................................................9

1. HARDWARE DEBUG ...................................................................................................................... 9

1.1 DIAL-UPSETTING......................................................................................................................... 9

1.2 LED DISPLAY............................................................................................................................... 10

1.3 DI/DO..............................................................................................................................................11

2.COMMUNICATION DEBUG.......................................................................................................... 12

2.1 COMMUNICATION DEBUG WITHAIR CONDITIONING EQUIPMENT.............................. 12

2.1.1 BACnet GATEWAY CONFIGURATION................................................................................. 13

2.2 COMMUNICATION DEBUG WITH BMS SYSTEM EQUIPMENT......................................... 13

2.3 EXCEPTION HANDLING............................................................................................................ 14

PART III MAINTENANCE....................................................................................................................... 16

1.COMMON TROUBLESHOOTING OF BMS SYSTEM............................................................... 16