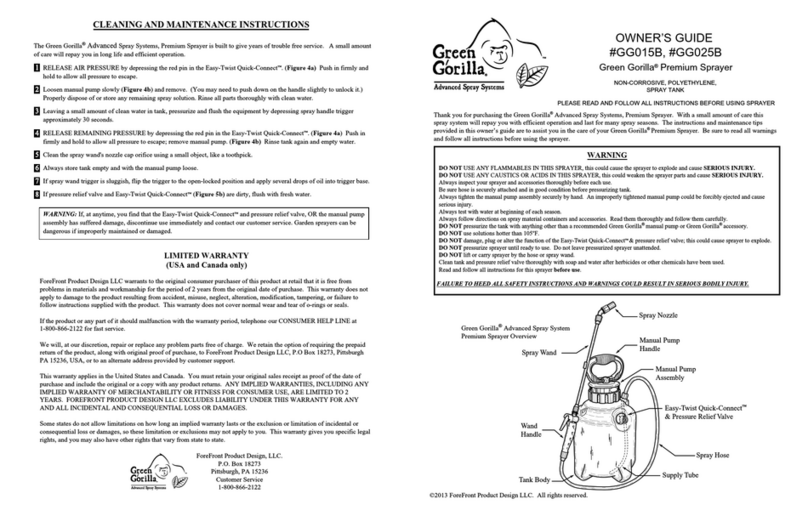

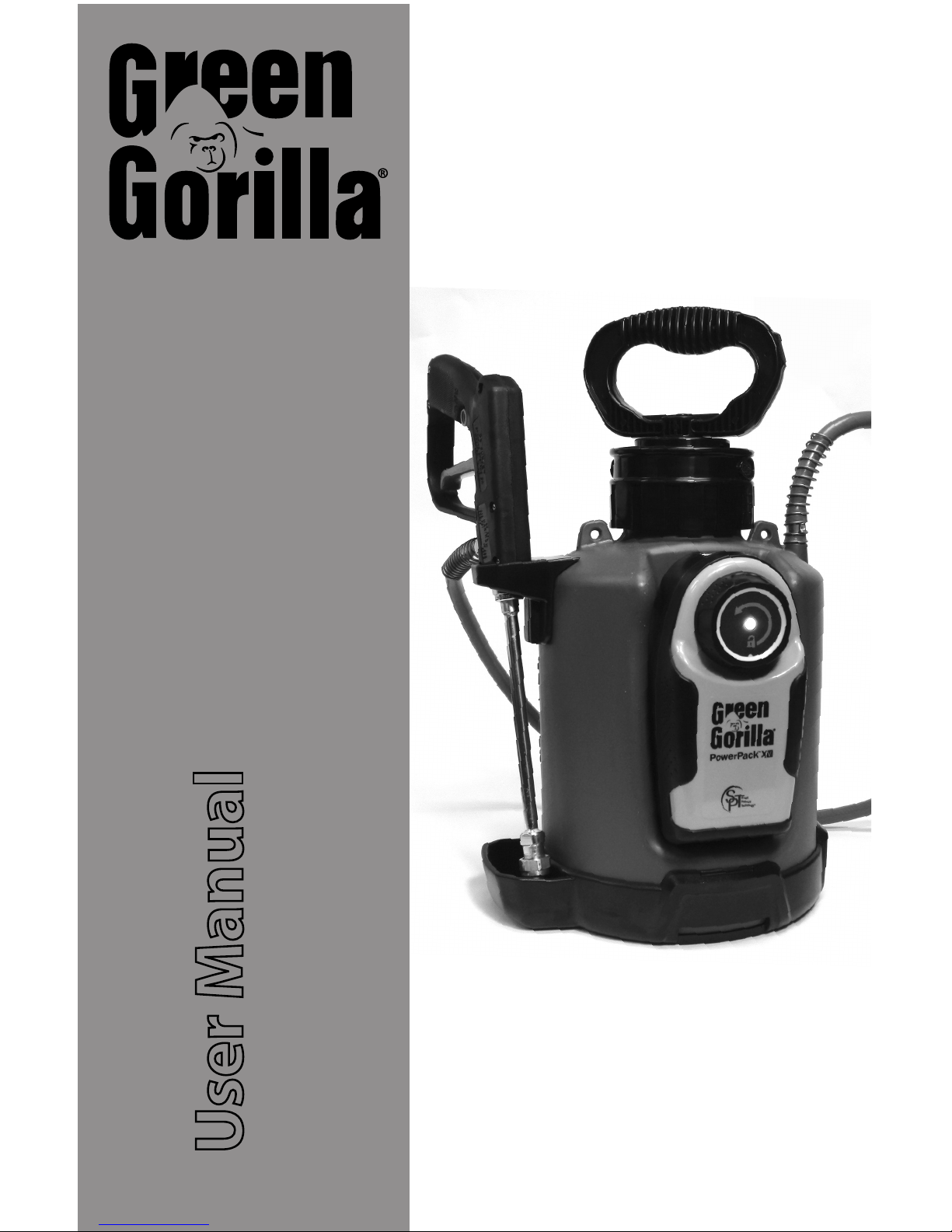

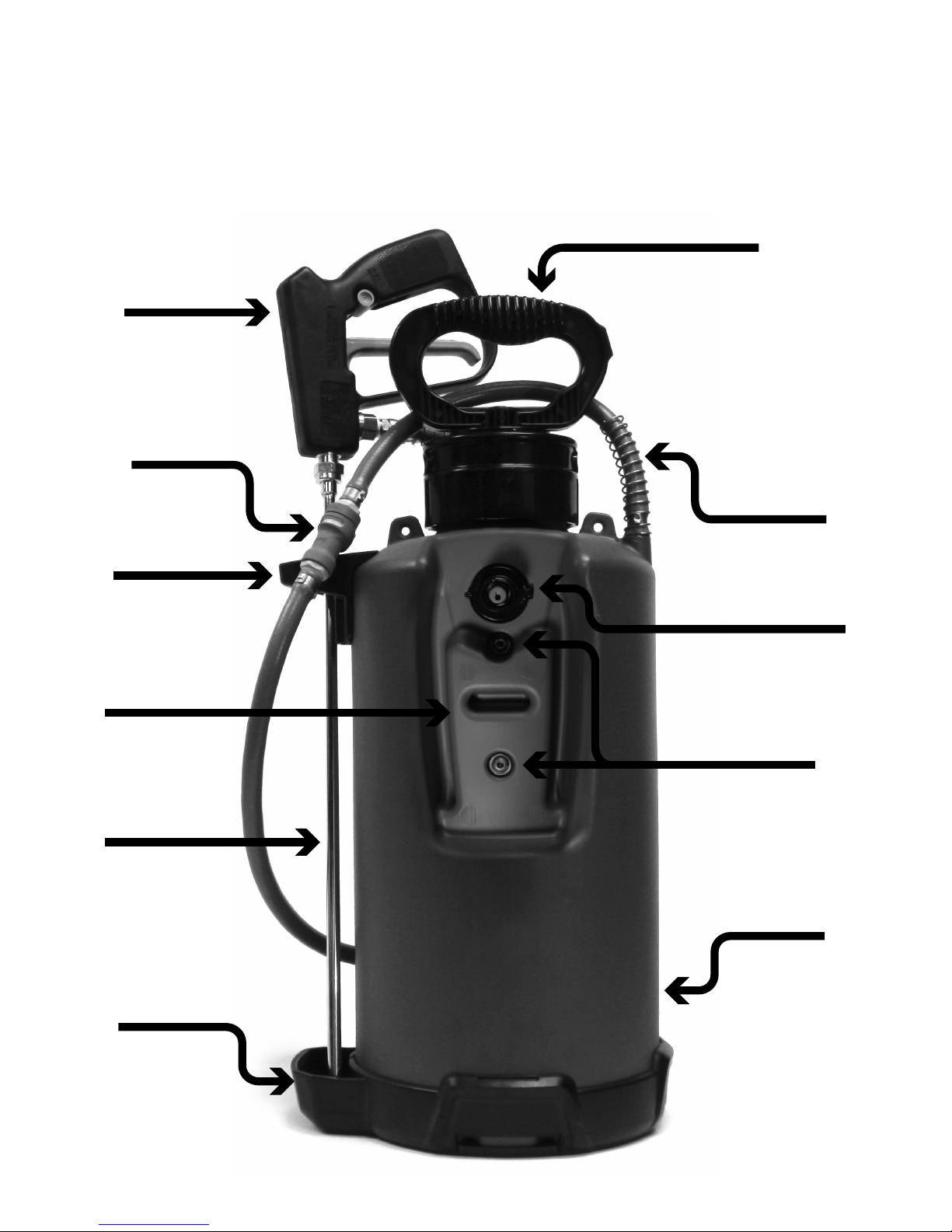

Congratulations on purchasing the rst intelligent compressed air spray system. With

the Green Gorilla ProLine Spray System you now have precision control when apply-

ing your product. Your Green Gorilla ProLine tank is equipped with a patented

Quick-Connect tting that allows the PowerPack to easily attach to the tank,

completely automating the pressurization process and precisely controlling the

pressure using Smart Pressure Technology (SPT™).

The instructions and maintenance tips provided in this owner's guide will assist you in

the care of your Green gorilla ProLine tank. Be sure to read all warnings and follow all

instructions before using the sprayer.

Warning and Cautionary Statements

Warning: When using solvent based products ensure the area is well ventilated with no open ames.

Fumes generated by certain products can be injurious to your health. Always operate the sprayer in

well ventilated areas and don protective equipment per the manufacturer’s recommendations for the

product being delivered. Never spray solvent based products in an enclosed area.

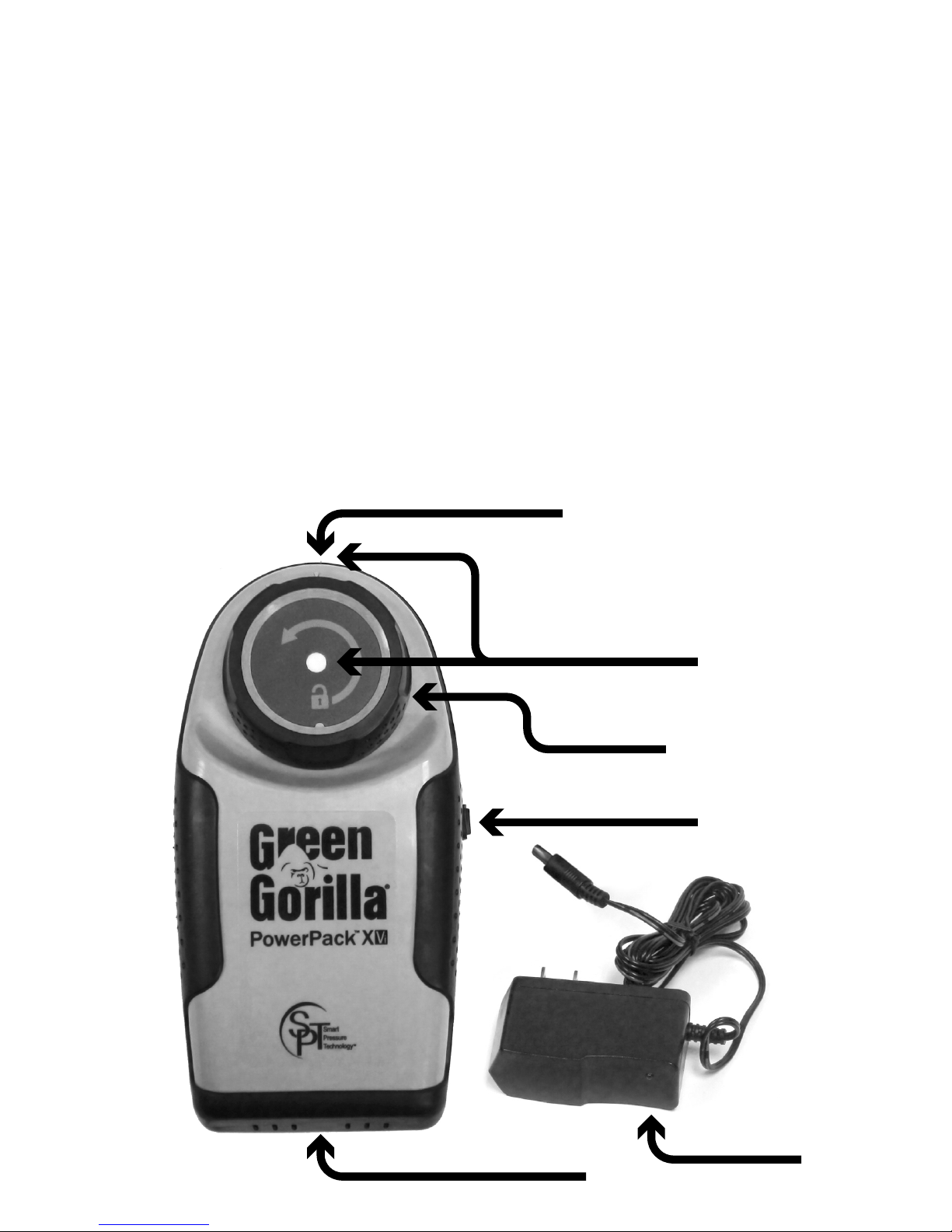

Warning: Never charge the PowerPack in temperatures below 32° F or above 110° F. This can result in

battery damage and/or re.

Warning: It is imperative that the original charger for the Green Gorilla system is used as dierent

chargers may not have the built in protection necessary to ensure a safe charging condition.

Warning: Do not pressurize the tank with anything other than genuine Green Gorilla parts and

accessories.

Warning: Do not use mechanical devices to pressurize tank other than recommended Green Gorilla

Power Packs and accessories.

Warning: Do not stand over tank while tank is pressurized. Securely tighten hand pump as instructed; a

loose pump could be forcibly ejected.

Warning: Do not alter or plug Quick-Connect valve, sprayer could explode. This is a safety device.

Caution: Do not ll tank above listed operating capacity.

Caution: Do not pressurize sprayer until ready to use or leave pressurized sprayer unattended.

Caution: Do not lift or carry sprayer by hose.

Caution: Do not use solutions hotter than 105° F. Damage may occur.

Important: Triple rinse tank and pressure relief valve between chemical change outs to ensure no cross

contamination.

Caution: Do not store outdoors or leave PowerPack in the rain. PowerPack is water resistant

but not water proof.

Warning: Do not charge the PowerPack in the rain or damp location. Charge in warm, dry location only.

Pg. 2

!

!

!

!

!

!

!

!

Safety Rules