www.GreenSeriesFitness.com ©May 2015 Call Toll free (800) 269-7140

CIR-TM6000DC-G Revision 1.1

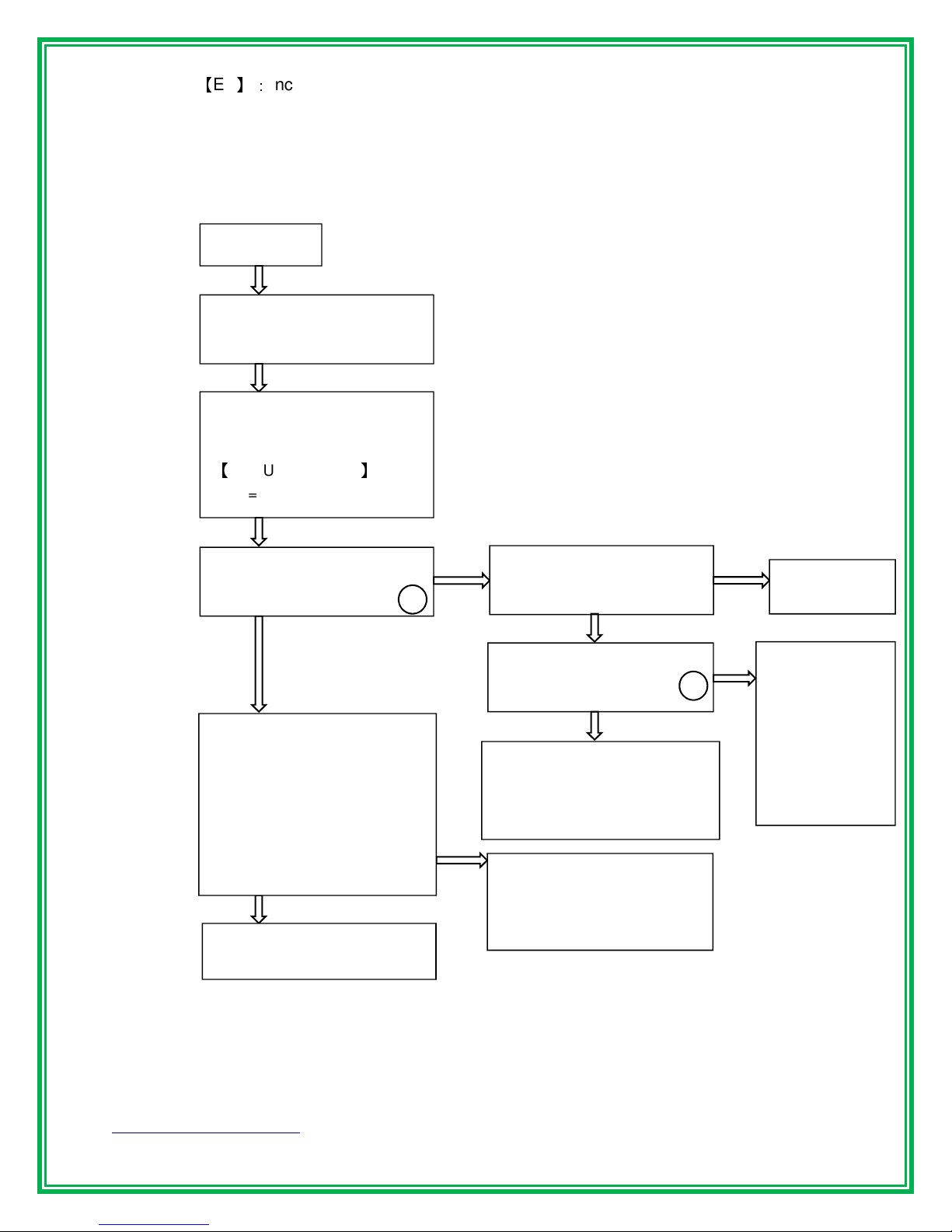

2.2.

【

Err

】:

Incline cannot reach the right position, incline function cannot be use but other

functions are normal to use.

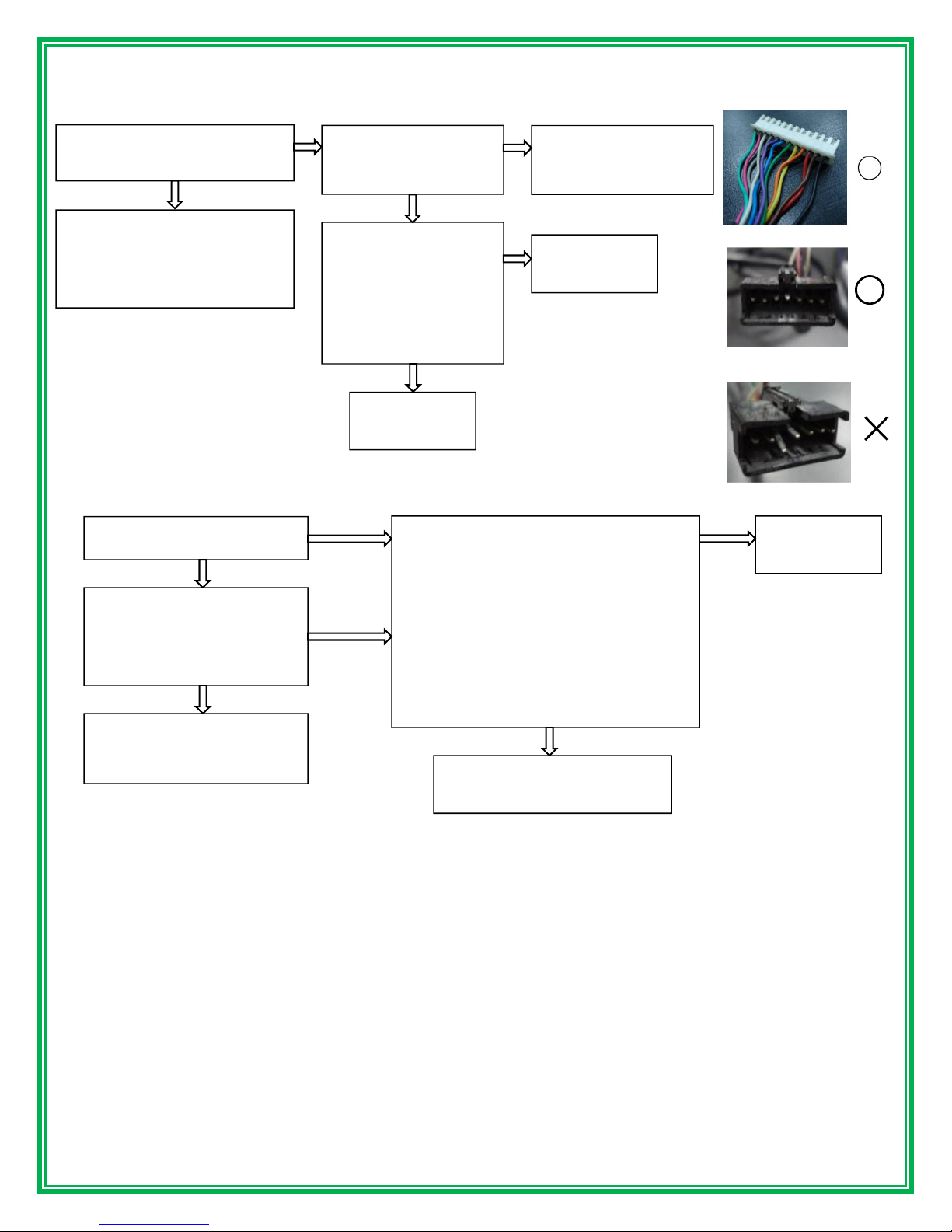

*If this is a new product that has just finished being assembled, there is a possibility of

problems in assembly. Check the wire connections and confirm that the wires and cables

have not been damaged during assembly.

Determine Cause and Solution:

Remark A: Before installing a new incline motor or Variable Resistor (VR), be sure to have the

incline level set to zero ( 0 ).

Showing ERR

Turn OFF the AC power and

wait for 10 seconds and then

Pull out the safety key, press

STOP and UP to enter the

engineering mode, displays

【

MANUAL INC XXX

】

(XXX=Incline parameter)

Did the incline move while

pressing the incline UP or

Did the D5 or D6 lamps

illuminate while pressing the

Replace the

console PCB

Check the surface

temperature of the incline

Strip the incline

motor down to

check for

movement

obstructions or

jamming. If the

incline motor is

good, replace the

motor controller.

Wait for cool down and then

repeat step A. If the incline

motor does not work after the

cool down, proceed to step B.

Did the incline motor move

and the incline parameter

change while pressing the

incline UP and DOWN key.

(Parameter range is from the

lowest to highest position, 15

to 195. Check this value

range. Incline motor faulty. Replace

the incline motor or the

variable resistor (VR).

(Remark A)

Incline motor is good. Press

STOP to go back to idle state.