8

BASE PREPARATION

You have quite a choice in terms of the style of base that you can prepare. The most important

objective is that it is level. The different styles of bases that we recommend are as follows:

Note:Your greenhouse size is only nominal, for example a 6 X 8 greenhouse is not

exactly 6’ by 8’! It will actually be a few inches bigger. So be careful when building

your base as mistakes on the size of your base are difficult to correct later. Also we

don’t recommend building your greenhouse directly onto soil.

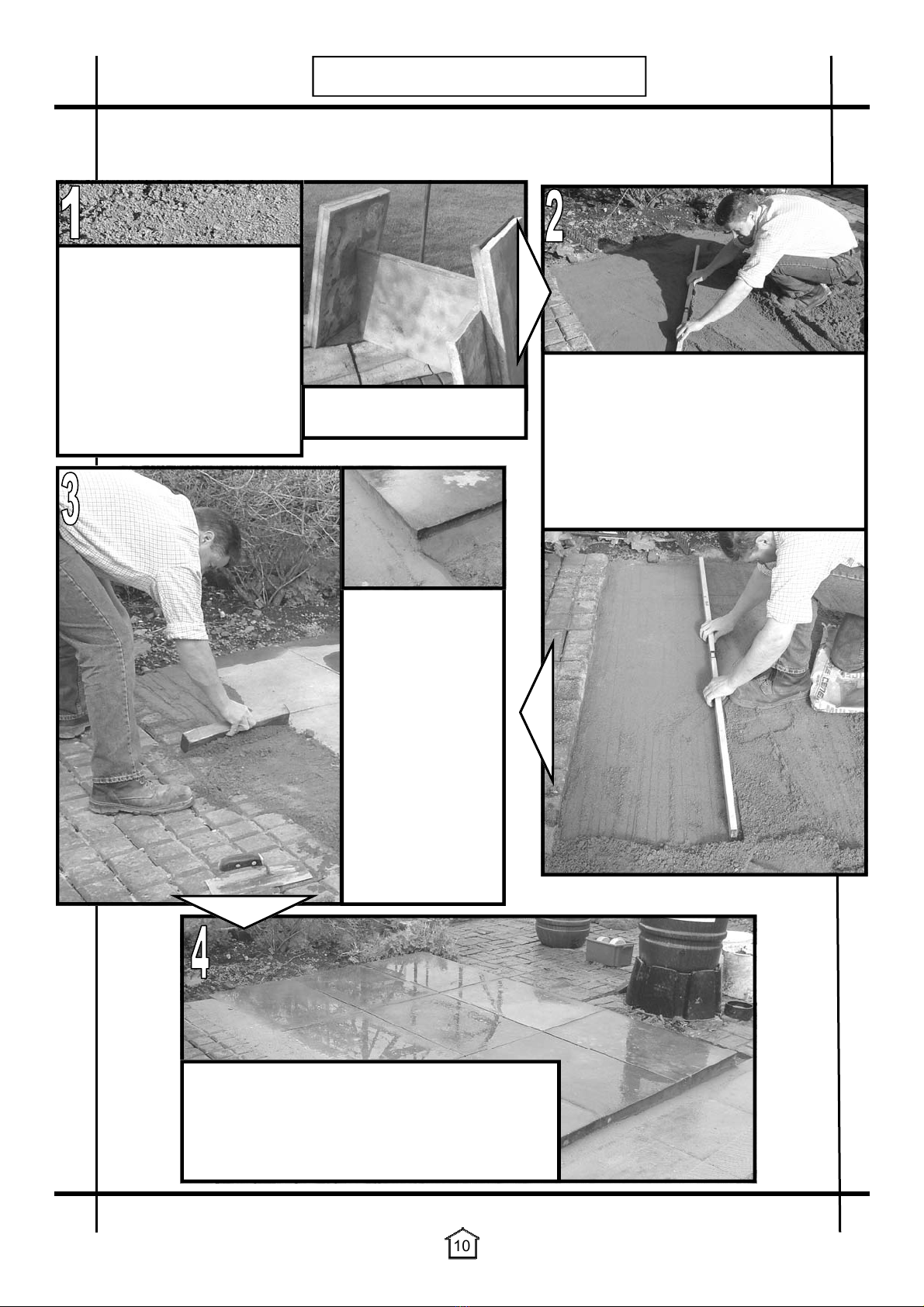

1. Slabs - Level paving slabs are ideal for a greenhouse base. Make sure the area of

slabs is either the same size or larger than the footprint of the greenhouse. Slabs are

also good for drainage because of the joints between them. If you put a polythene

sheet or similar barriers underneath, this could prevent drainage. (See page 10 for a

quick guide to laying slabs).

You can also lay your slabs out as a perimeter around the edge of the building with a

path up the middle if you want to grow directly from the soil.

2. Concrete Plinth - This is a simple footing around the edge of the greenhouse. You

can do this by digging a small trench about 4-6” deep by 6” wide. As with all bases

ensure that it is level along the length as well as side to side. If you don’t have a long

level then you could use a long bar or straight piece of wood under your level to get a

more accurate reading. This is probably the cheapest and easiest base to build

which enables you to have soil inside so that you can grow straight from the ground.

3. Solid Concrete - This type of base is good from a structural point of view as you can

get good fixings. It is also fine as far as drainage is concerned as long as the

concrete is not sealed, painted or laid on a membrane.

Ways of increasing drainage are: When laying the concrete you could lay Aco drive

drains to take surface water away or if the concrete is already laid you could simply

drill through the concrete and create soakaways.

4. Brick Base - This is the traditional greenhouse base. It is usually 1 or 2 courses high

but can be higher if required. This is a much more costly and difficult base to install.

This is because you need to make a concrete footing first, then you need to lay the

courses of bricks to the millimetre so that they fit the cill of the greenhouse perfectly.

However it does have an advantage, the cill overlaps the brick edge minimising water

flow under the cill, which is important if you need to control the humidity and are using

a de-humidifier etc.

Important: Always use a completely solid engineering brick for the top layer with no

holes or frogs (such as Staffordshire Blue). This is because you’ll need to anchor

your greenhouse down by drilling and screwing into the bricks and if they have holes

in then this is extremely difficult. If you are doing more than one course then you can

use bricks with holes or frogs lower down where it will not matter.

See page 9 for external dimensions.

Two different styles of base that we don’t recommend:

1. Block Paving - This is not an ideal base for a greenhouse. This is because when you

screw your greenhouse down you will only be screwing into loose blocks, which will

not be a strong enough fixing.

2. Tarmac - Again not ideal because of the anchoring problems, and it is much harder to

get a level surface. However if you do want to put your greenhouse on tarmac, then

the way to anchor it will be as on soil. You can dig out spade width holes where each

base bracket will situate and fill these with concrete, let it set, then when your green-

house is in position you can screw into the concrete.