Greentec HS172-212-242 Cutterbar

4

Indholdsfortegnelse

PREFACE ______________________________________________________________________________________ 5

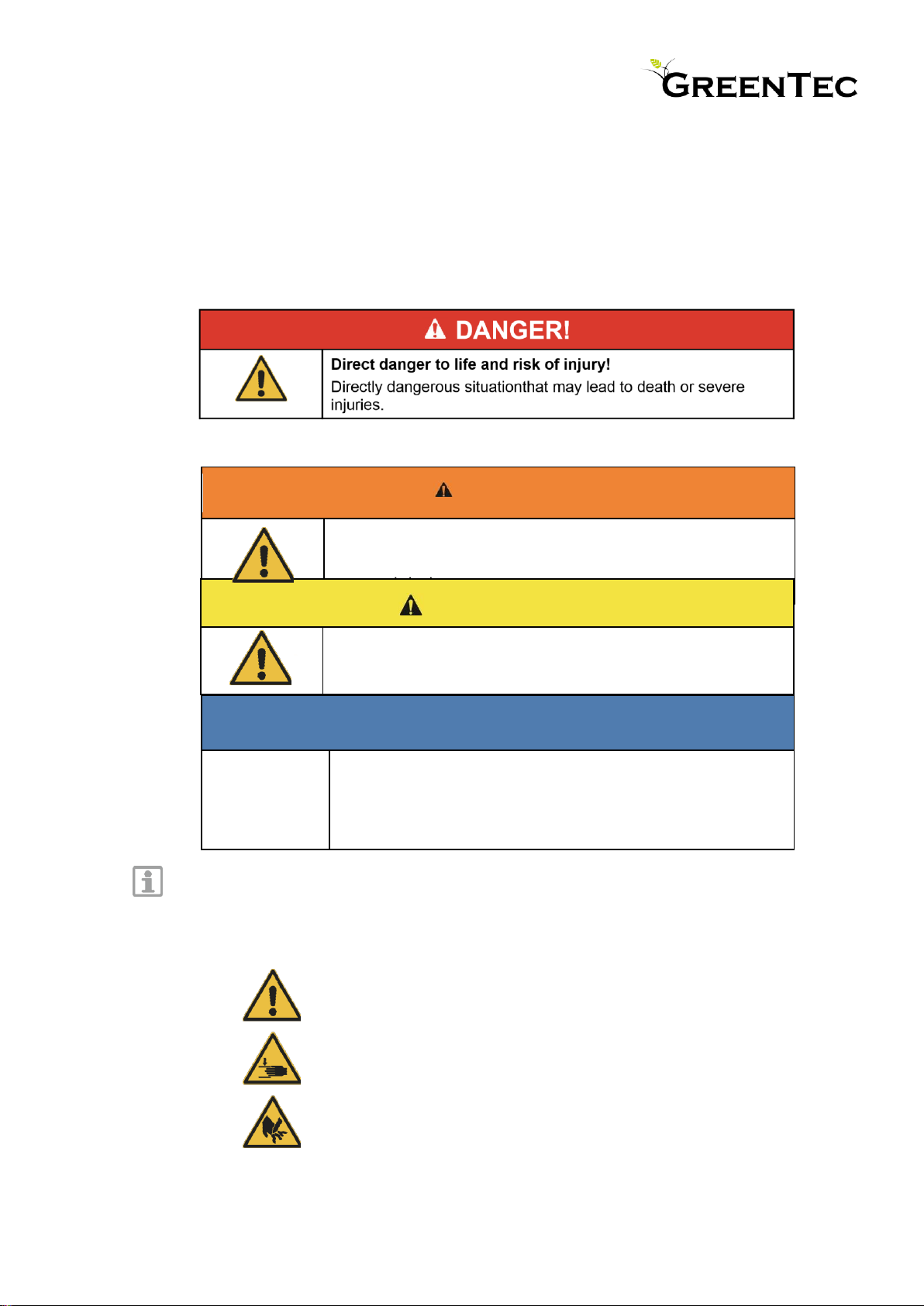

Useful information ______________________________________________________________________ 6

Generel information in the use of the instruction manual _______________________________________ 7

Declaration of Conformity ________________________________________________________________ 9

SAFETY______________________________________________________________________________________ 10

Intended use __________________________________________________________________________ 10

Unauthorized conversions and modifications are prohibited____________________________________ 10

Personnel qualification and training _______________________________________________________ 10

General safety information_______________________________________________________________ 10

Safety information for operation __________________________________________________________ 11

Safety information for assembly, maintenance and repair work _________________________________ 12

Personal safety equipment_______________________________________________________________ 13

Safety labels __________________________________________________________________________ 14

DESCRIPTION ______________________________________________________________________________ 15

Overview of the cutterbar, type plate, warning plates and instruction plate _______________________ 15

_____________________________________________________________________________________ 15

Layout and function ____________________________________________________________________ 16

Technical data _________________________________________________________________________ 17

ATTACHMENT AND REMOVAL __________________________________________________________ 18

Delivery ______________________________________________________________________________ 19

Mounting_____________________________________________________________________________ 19

Start-up ______________________________________________________________________________ 21

Hedge trimming _______________________________________________________________________ 22

Transport_____________________________________________________________________________ 23

Demounting___________________________________________________________________________ 23

STORAGE AND MOVING THE MACHINE ________________________________________________ 24

Storage ______________________________________________________________________________ 24

Maintenance __________________________________________________________________________ 25

Maintenance schedule __________________________________________________________________ 26

Cleaning______________________________________________________________________________ 27

Parts replacement______________________________________________________________________ 28

Lubrication ___________________________________________________________________________ 42

Parts_________________________________________________________________________________ 42

TROUBLESHOOTING ______________________________________________________________________ 44

BILAG 1 _____________________________________________________________________________________ 45

Tightening torques _____________________________________________________________________ 45