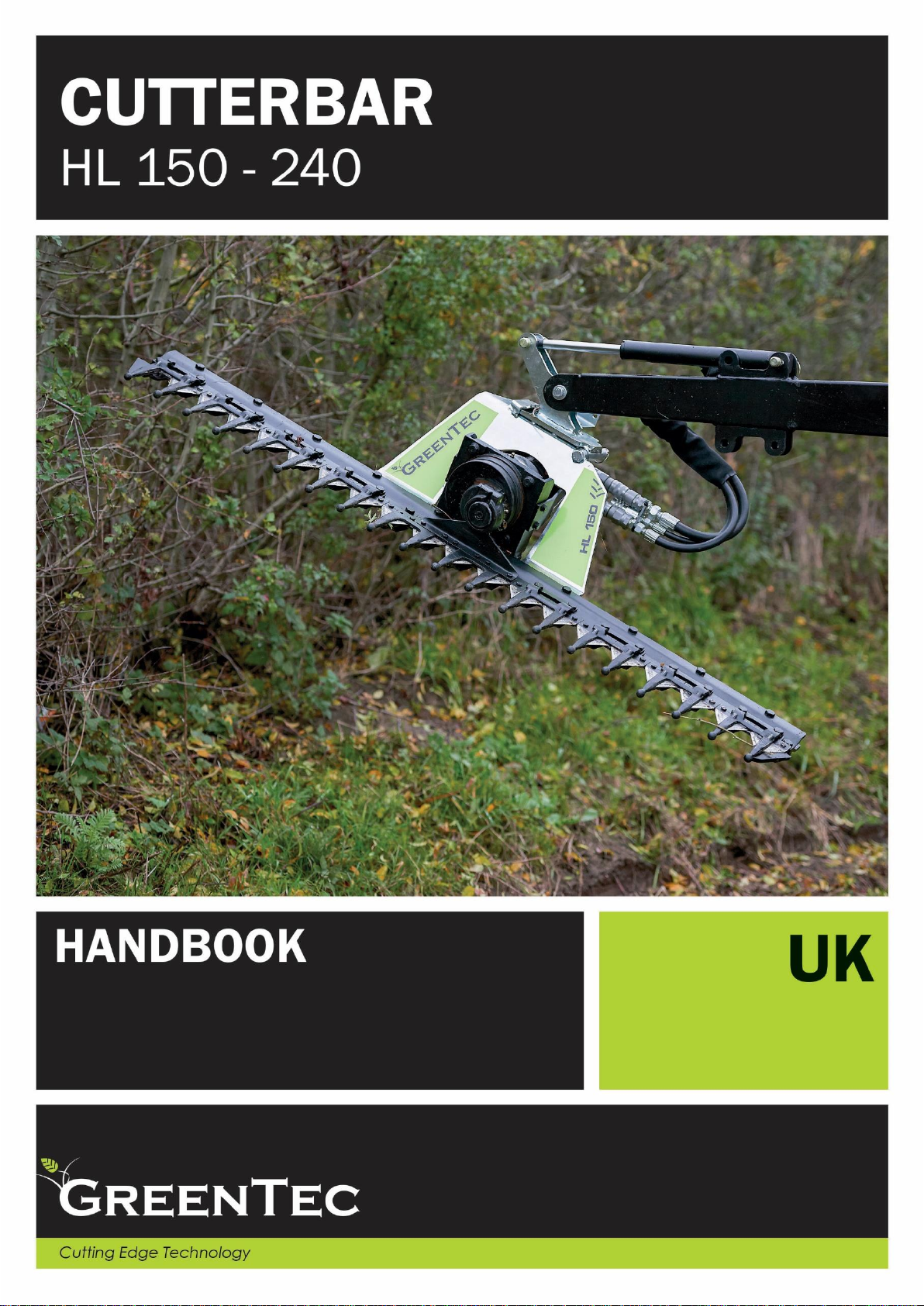

Cuttterbar 150-180-210-240

List of contents

INTRODUCTION .................................................................................................................5

USEFUL INFORMATION....................................................................................................6

ORDERING PARTS ............................................................................................................7

1EU Declaration of Conformity ....................................................................................8

2General.........................................................................................................................9

2.1 Signs ................................................................................................................................9

2.2 Load capacity ...................................................................................................................9

2.3 Energy requirement ..........................................................................................................9

2.4 Connections....................................................................................................................10

2.5 Intended use...................................................................................................................10

2.6 Technical data sheet.......................................................................................................10

3Safety .........................................................................................................................12

3.1 Staff qualifications and training .......................................................................................13

3.2 The dangers of disregarding safety directions.................................................................13

3.3 Being safety-conscious...................................................................................................13

3.4 Safety directions for the person in charge/the user .........................................................14

3.5 Safety directions for maintenance, inspection and assembly tasks.................................15

3.6 Conversion and production of spare parts.......................................................................15

3.7 Inadmissible operation methods .....................................................................................16

3.8 Warning signs on the hedge trimmer ..............................................................................16

4HL Cutterbar: HL 150 to HL 210 ..............................................................................18

4.1 Signs and labels .............................................................................................................18

4.2 Storage...........................................................................................................................19

4.3 Description of the HL Cutterbar.......................................................................................19

4.4 Mounting.........................................................................................................................19

4.5 Mounting on to tractor/vehicle.........................................................................................20

4.6 Putting the trimmer into operation...................................................................................21

4.7 Transport........................................................................................................................21

4.8 Transporting the trimmer.................................................................................................22

4.9 Working positions ...........................................................................................................22

4.10 Disassembly...................................................................................................................22

4.11 Maintenance and repair..................................................................................................22

4.12 Lubrication......................................................................................................................23

4.13 Defects, causes and correction.......................................................................................24

4.14 Hydraulics diagram.........................................................................................................24

4.15 Manufacturer’s address ..................................................................................................24

5Torques......................................................................................................................25

6Assemble/disassemble.............................................................................................26

6.1 Montage / Demontage ....................................................................................................26

6.2 Flow og speed diagram...................................................................................................30