INTRODUCTION

Congratulations on purchasing a first-class British designed and manufactured Turf Maintenance System!

To ensure operator safety and obtain maximum service life from this machine it is essential that ALL operators

read and thoroughly understand this manual. If at any time there is anything you are unsure about, the

manufacturers will be pleased to help.

SAFETY WARNINGS

This turf maintenance system is designed to be operated by a tractor of not less than 35HP with a hydraulic

lifting capacity of at least 1 tonne. Front weights may be necessary when operating this machine.

All operators must also read and follow all instructions in the operators handbook supplied with the tractor.

Check that the brakes are applied, drives are in neutral, guards are in position and intact and bystanders

are clear of the machine. Do not run the engine in a building without adequate ventilation.

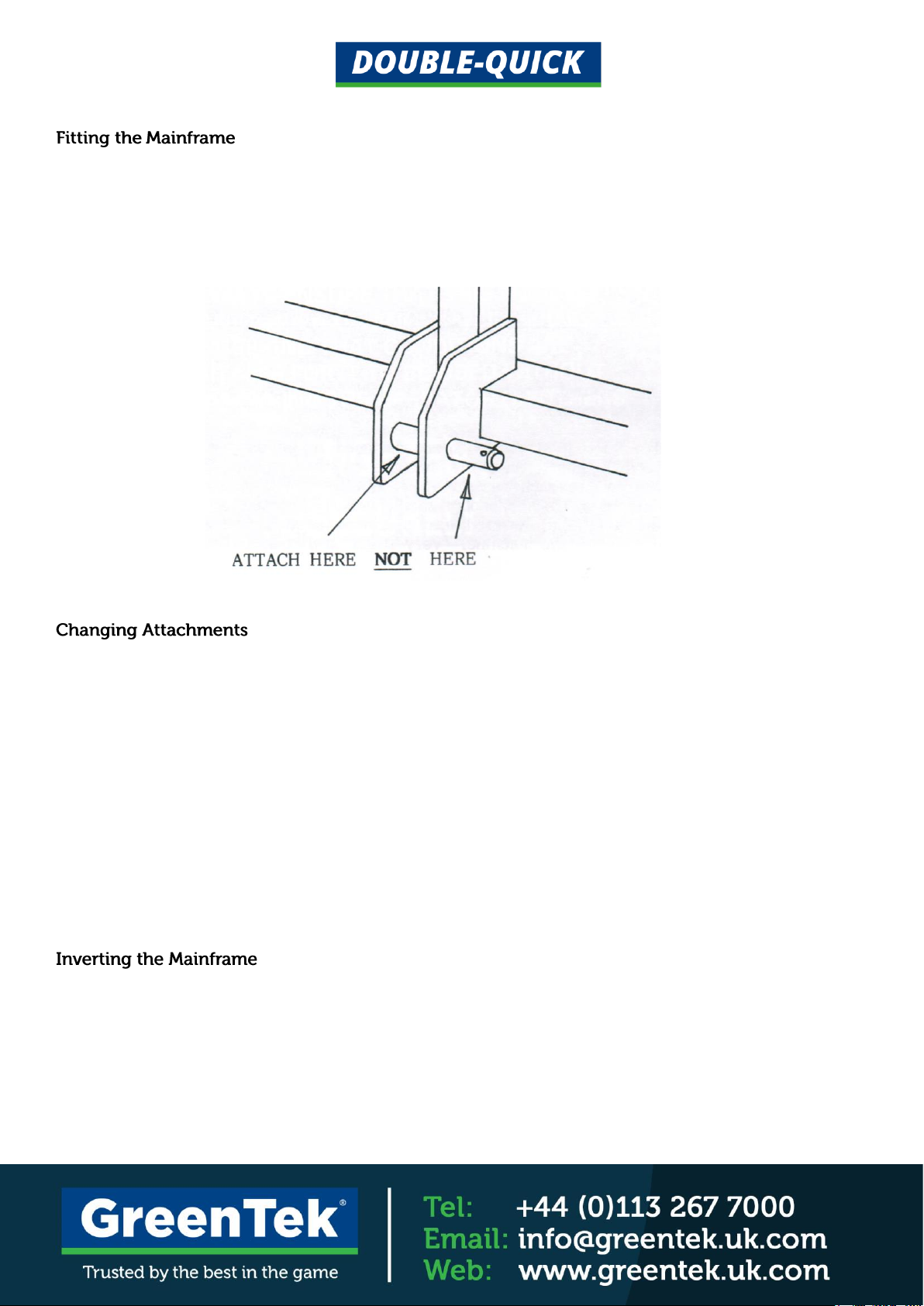

Before moving the machine, check to ensure that all the parts are in good working order, paying particular

attention to tyres, steering, brakes and lights. Double check that the attachment is fitted securely to the

tractors’ 3 point linkage.

Always observe the Highway Code both on and off the roads. Keep alert and aware at all times. Remember

that some people are deaf or blind; that children and animals can be unpredictable. Keep travelling speeds

low enough for an emergency stop to be effective and safe at all times.

Take special care when reversing and ensure the area behind is clear of obstructions. Remove or avoid

obstructions in the working area.

Park the tractor on level ground. Before leaving the driving seat, stop the engine and make sure all moving

parts are stationary. Apply brakes and disengage all drives. Remove the ignition key.