G-FIRE Figure 579

Grooved Rigid Coupling

2 Inch to 8 Inch (DN50 to DN200)

Worldwide

Contacts

www.tyco-fire.com

Page 1 of 6 FEBRUARY 2019 TFP1856

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

General

Description

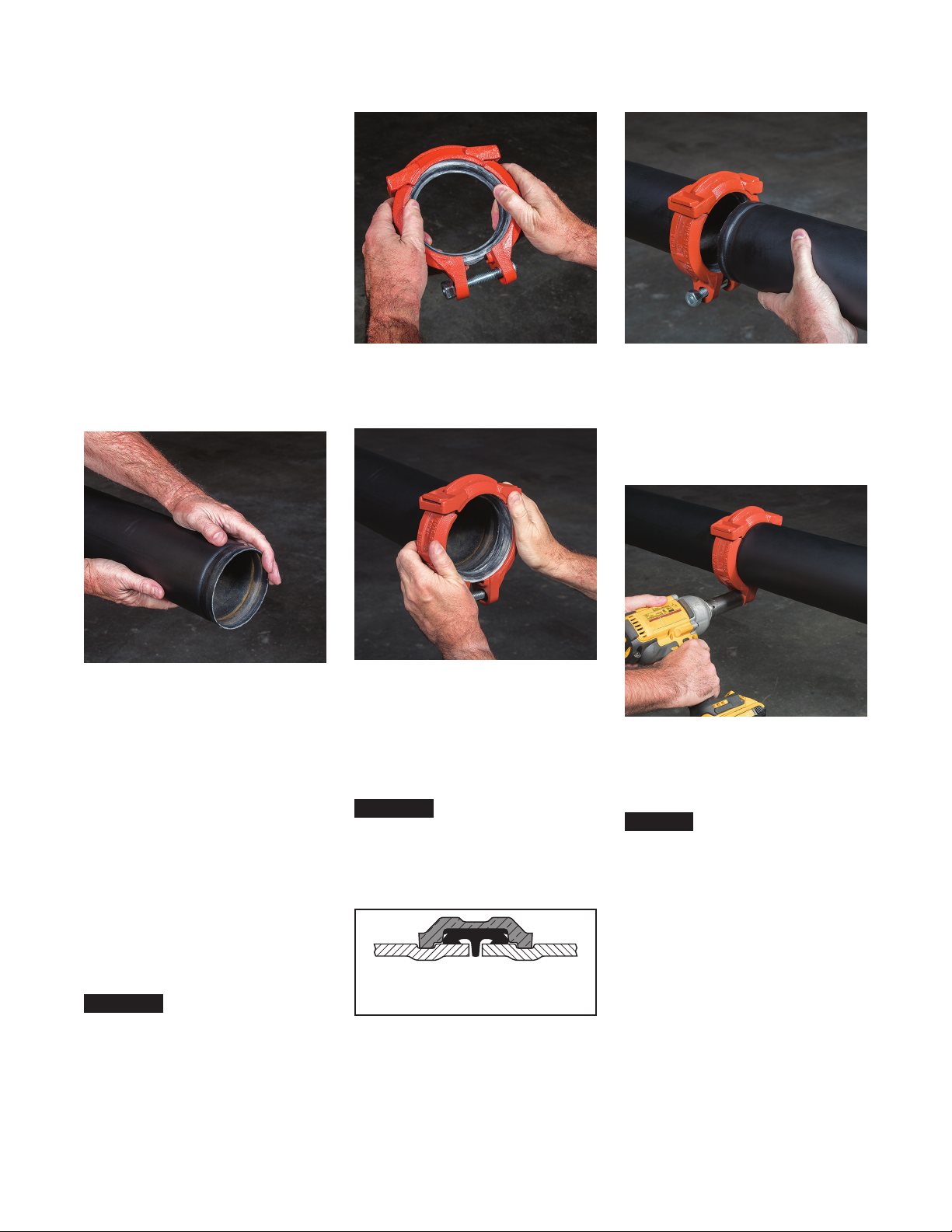

The GRINNELL G-FIRE Figure 579

Grooved Rigid Couplings provide a

rigid joint by firmly gripping along the

full circumference of the pipe grooves.

Figure 579 couplings are a dependable

method of joining pipe and are an eco-

nomical alternative to welding, thread-

ing, or using flanges.

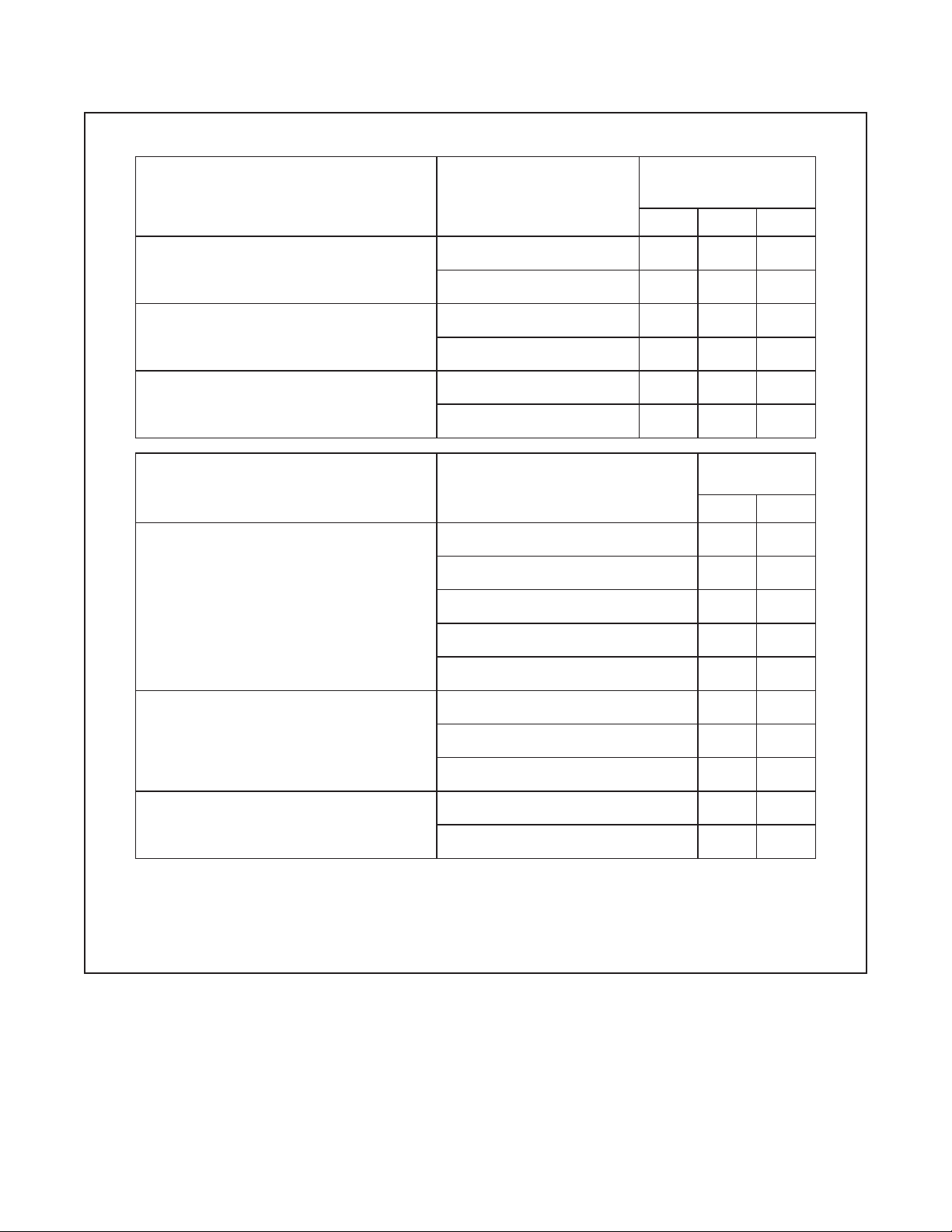

Figure 579 couplings are rated at pres-

sures up to 365 psi (25,2 bar) depend-

ing on pipe size and wall thickness

when used in fire protection service

applications. Refer to Table A.

NOTICE

The GRINNELL G-FIRE Figure 579

Grooved Rigid Coupling described

herein must be installed and main-

tained in compliance with this docu-

ment, as well as with the applicable

standards of the Approval agency, in

addition to the standards of any other

authorities having jurisdiction. Failure

to do so may result in serious personal

injury or impair the performance of

these devices.

Never remove any piping component

nor correct or modify any piping defi-

ciencies without first de-pressurizing

and draining the system. Failure to do

so may result in serious personal injury,

property damage, and/or impaired

device performance.

It is the designer’s responsibility

to select products suitable for the

intended service and to ensure that

pressure ratings and performance

data are not exceeded. Material and

gasket selection should be verified to

be compatible for the specific applica-

tion. Always read and understand the

installation instructions.

The owner is responsible for main-

taining their mechanical system and

devices in proper operating condi-

tion. Contact the installing contrac-

tor or device manufacturer with any

questions.

Technical

Data

Approvals

UL and ULC Listed

FM Approved

Refer to Table A for details.

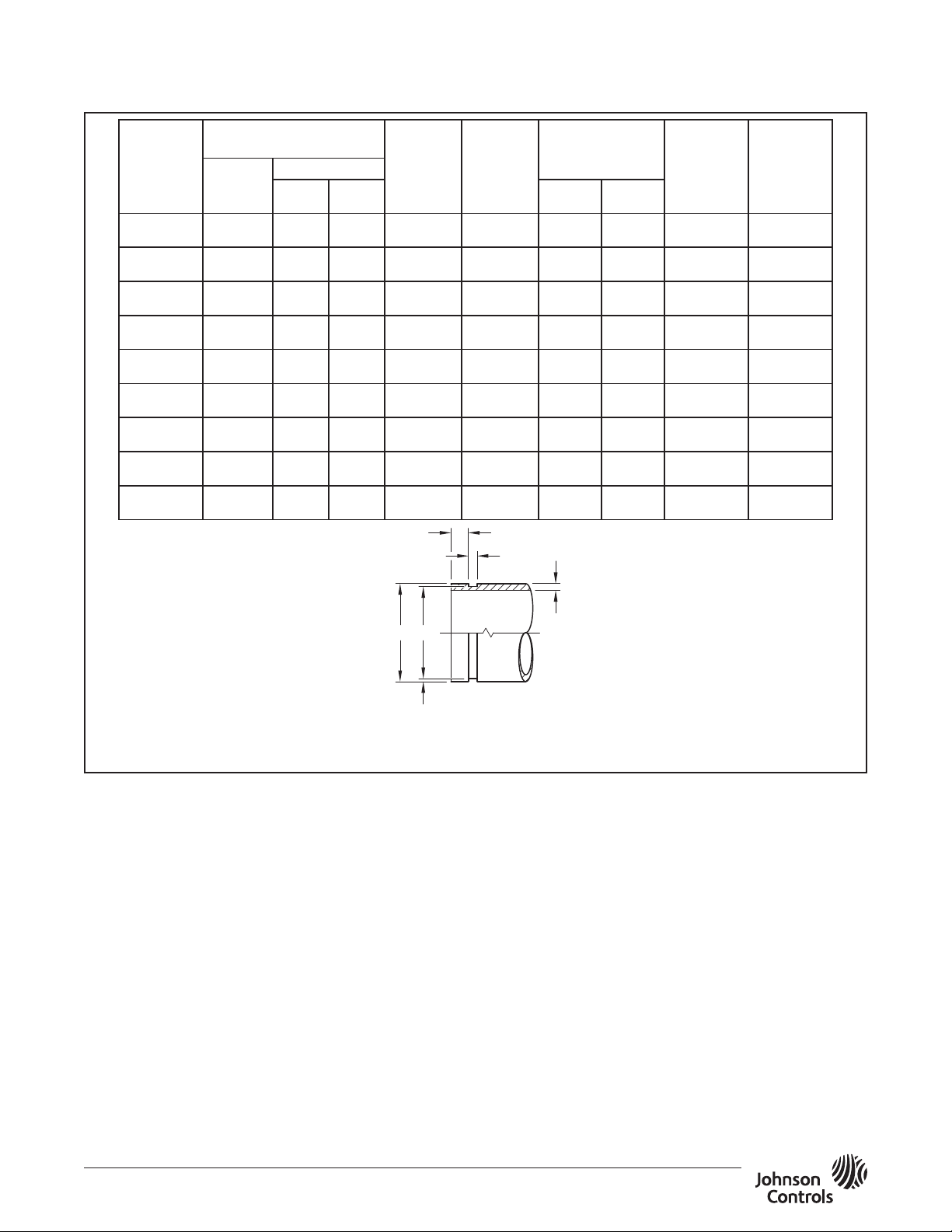

Sizes

2 in. to 8 in. (DN50 to DN200)

Housing

Ductile iron conforming to ASTM A536,

Grade 65-45-12

Finish

• Orange non-lead paint

• Red non-lead paint

•

Hot-dipped, Galvanized conforming

to ASTM A153

Bolt/Nut

• ANSI:

Carbon Steel oval neck track head

bolts are heat-treated and conform

to the physical properties of ASTM

A183 Grade 2 and SAE J429 Grade

5 with a minimum tensile strength of

110,000 psi.

Carbon Steel heavy hex nuts con-

form to the physical properties of

ASTM A183 Grade 2 and SAE J995

Grade 5. Bolts and nuts are zinc-

electroplated conforming to ASTM

B633.

• Metric:

Carbon Steel oval neck track head

bolts (Gold color coded) are heat-

treated and conform to the physical

properties of ASTM F568M with a

minimum tensile strength of 760

MPa.

Carbon Steel heavy hex nuts con-

form to the physical properties of

ASTM A563M Class 9. Bolts and

nuts are zinc-electroplated conform-

ing to ASTM B633.

For Fire Protection pressure rating,

listing, and approval information, contact

your GRINNELL Representative.

Gaskets

• Pre-lubricated Grade “A” EPDM,

Violet color code,

-30°F to 150°F (-34°C to 66°C)

For dry and freezer systems, lubrica-

tion is required. Refer to Installation

Manual IH-1000FP for details.

For proper gasket selection, refer to

Technical Data Sheet TFP1895.