RAZOR SHARP EDGEMAKING SYSTEM

INSTRUCTIONS

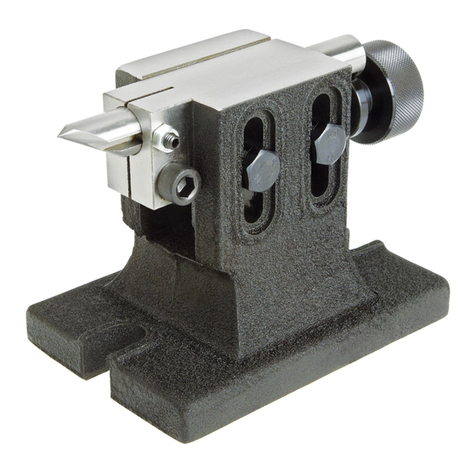

TO INSTALL WHEELS: You will nee to remove the guar s from your

bench grin er, as they are not nee e with this paper wheel. Then in-

stall the gritte wheel on the right si e of the motor an the slotte

wheel on the left si e of the motor.

Before you turn on the motor, take the con itioning wax (yellow stuff)

out of the cup an rub it sparingly on the black grit wheel until you can

see some wax on the grit. Then each time you start to sharpen, just

touch the wax to the grit wheel for a secon with the motor running. The

wax has two functions; a) helps control heat & b) helps the grit stay on

the wheel longer. Be careful not to use too much wax, oing so will e-

stroy the effectiveness of the grit. There shoul be streaks of wax

(shiny) on the grit, but if the wax is completely covering the grit it will

re uce the grit’s ability to cut into the steel.

The slotte wheel nee s no pre-con itioning just put it on an whenever

you start to use it, simply touch the running wheel with the rouge. This

is for heat control as well as for honing & polishing the cutting e ge.

Do not over-tighten the nuts. Snug is enough.

Spin the wheels by han . If a wheel wobbles from si e to si e try tap-

ping the wheel lightly with your fingers. If you still have a wobble,

loosen the nut an turn the washer, or washers, just a little. Turn one

washer one way an the other washer the other way. Snug the nut an

spin the wheel. You might have to repeat this a time or two to minimize

the wobble.

A little si e to si e eviation won’t hurt anything! Sometimes, if a wheel

is expose to heat or ampness, it will warp a little. Place the wheel be-

tween two boar s, clamp them tightly an keep in a cool ry place for a

few hours!

Grit Packs containing replacement grit, wax for the gritte wheel an

rouge for the slotte wheel can be purchase from www.grizzly.com

(Item #G5941).

RECOMMENDED SPEED 3000 - 3600

Page Two

RECOMMENDED SPEED 3000 - 3600 RPM

RAZOR SHARP EDGEMAKING SYSTEM

TRUING OF WHEELS: When you have the wheels running “true” on’t

remove them unnecessarily, because when you put them back they will

be in a ifferent position an you will have to a just them again. Some-

times the wheels may be a little “out of roun ”. The grit wheel can be

fixe at time of re-surfacing. If the “slotte ” wheel seems out of roun ,

it can be true at any time. Correcting “out of roun ness” is easy. Take

a piece of 60 grit san paper an wrap it aroun a flat piece of metal (a

flat file works fine) & hol it lightly against the face of the wheel. You

will feel the “high” spot. Keep hol ing it lightly against the wheel until it

feels smooth. Now the “high” spot is gone & the wheel is clean & flat

across the face! Also you may “roun ” the corners of the slotte wheel

if you sharpen a lot of serrate knives. Simply use a fol e piece of 60

grit san paper to “sharpen” up the corners.

OKAY, YOU ARE READY TO START SHARPENING: Time to think about

the angle you want on your knife or tool. Proper angle epen s on what

you are going to use the e ge for! Generally, if you are going to chop,

ig or scrape with a bla e, a 35-40 egree angle works best. For razors

or a little rotary cutting wheel, a “flat” angle is best, 10-15 egrees.

Most knives are 20-25 egrees. You will learn with practice just what

angle works best for you.

RECONDITIONING the GRIT WHEEL:

Do not remove the wheel from the motor. If you o you will have to

eliminate the wobble again when you put it back on.

When the gritte wheel stops sharpening, use coarse san paper (like

36 grit) to clean off all the grit, glue & wax own to bare paper. Just

wrap it aroun something har & flat, like a crescent wrench han le or

flat file. After all the ol grit, wax & glue is remove , use 60 grit san pa-

per to smooth an true the wheel (as it might be a little out of roun ).

Next put some paper un er the wheel to catch excess grit, & put an

even coat of Elmer’s (“Ross” in Cana a) “Glue-All” multi-purpose white

glue on the face of the wheel. The layer of glue shoul not be too thin,

but not so thick as to be running off. You shoul be able to see the

laminate lines through the glue. Then slowly han turn the wheel while

you sprinkle the black silicon carbi e grit over the glue. Sprinkle the

grit on the wheel until it is sloughing off an no more will stick, then

turn the wheel a couple of times while tapping it on the si e to remove

excess grit. When you are happy with your coating job, pour the excess

grit back into the container an replace the li . Do not touch the wheel

until the glue ries completely, preferably for about 24 hours. Then it is

rea y to go again. If there is a small no ule on the wheel, wait until the

glue is ry, then turn on your motor & touch the running wheel slightly

with the 60 grit san paper. Some users have successfully use Tite-

Bon Original (re label) glue as well.