This chuck's compact size makes it ideal for use

on 12" (300 mm) capacity lathes and smaller.

The jaws are configured for both outside diameter

(O.D.) and inside diameter (I.D.) gripping. The

minimum gripping O.D. is 1.25", and the minimum

gripping I.D. is 1.8".

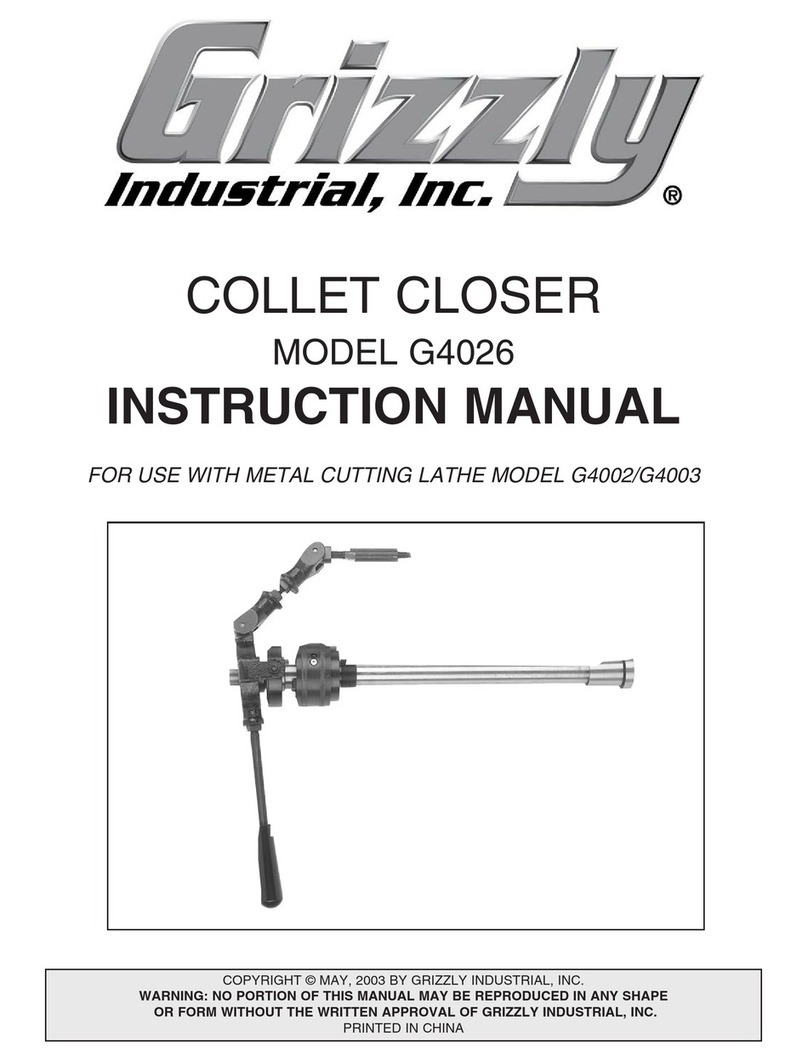

Opening/Closing Jaws

1. With the chuck mounted on the lathe, open/

close the chuck jaws so that the workpiece

can be placed between the jaws (Figure 3).

2. Insert the workpiece between the jaws. Be

sure that the workpiece is seated against the

jaw face.

3. Close/open the chuck jaws to securely clamp

the workpiece.

4. To remove the workpiece for the chuck,

open/close jaws until the workpiece is free.

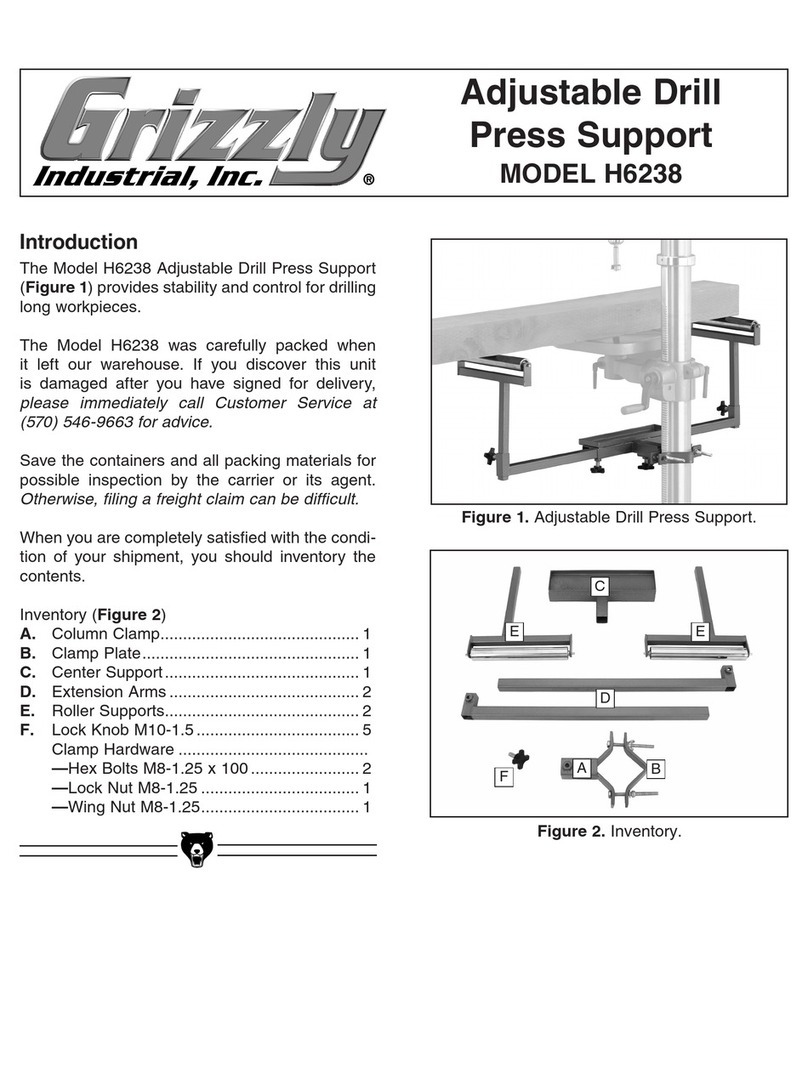

Wood Screw Use

This chuck is supplied with a wood screw for use

with small, cross-grained pieces.

1. Drill a 7-8 mm diameter hole that is 25 mm

deep, in the center of the workpiece.

2. Make sure the workpiece is as round as pos-

sible.

3. Mount the wood screw in the chuck with

the shoulder of the wood screw clamped

between the backing jaws (Figure 4).

4. Screw the workpiece onto the wood screw

until it is firmly against the jaws.

5. Unscrew workpiece once machining is com-

pleted.

Chuck Maintenance

To maintain the chuck, spray oil into the scroll and

work the jaws through their full range of motion.

Do this on a daily basis.

OPERATION INSTRUCTIONS

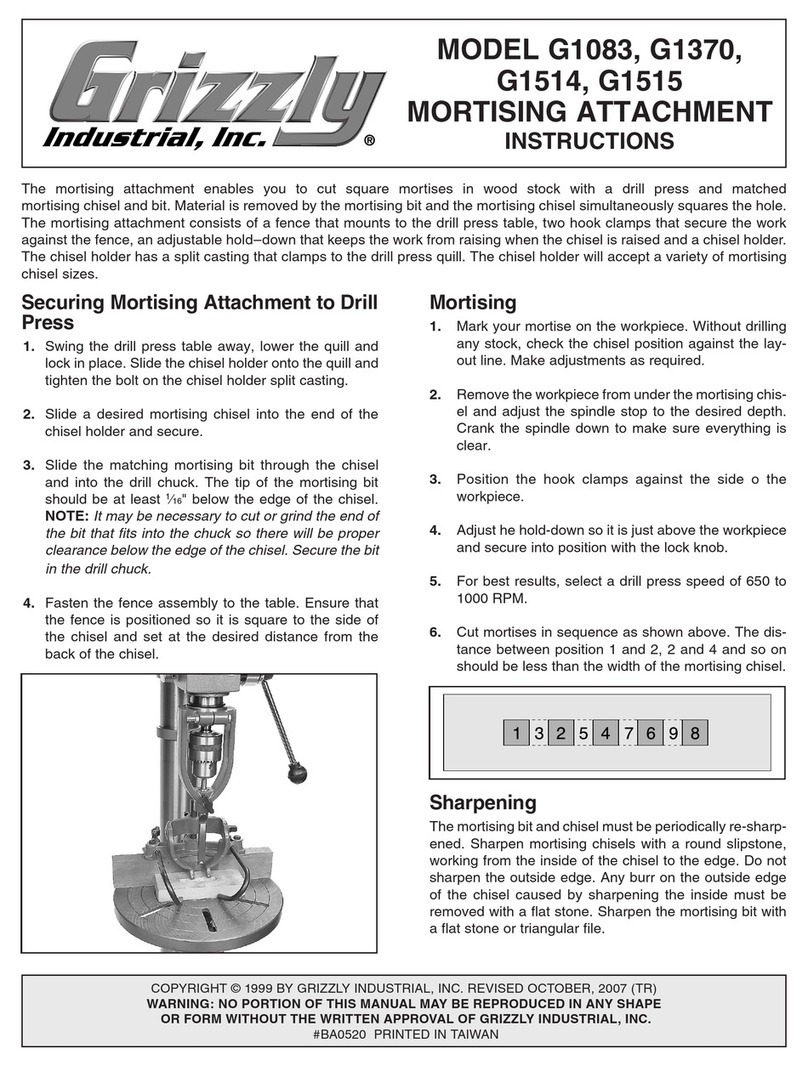

Figure 2. Chuck Operation.

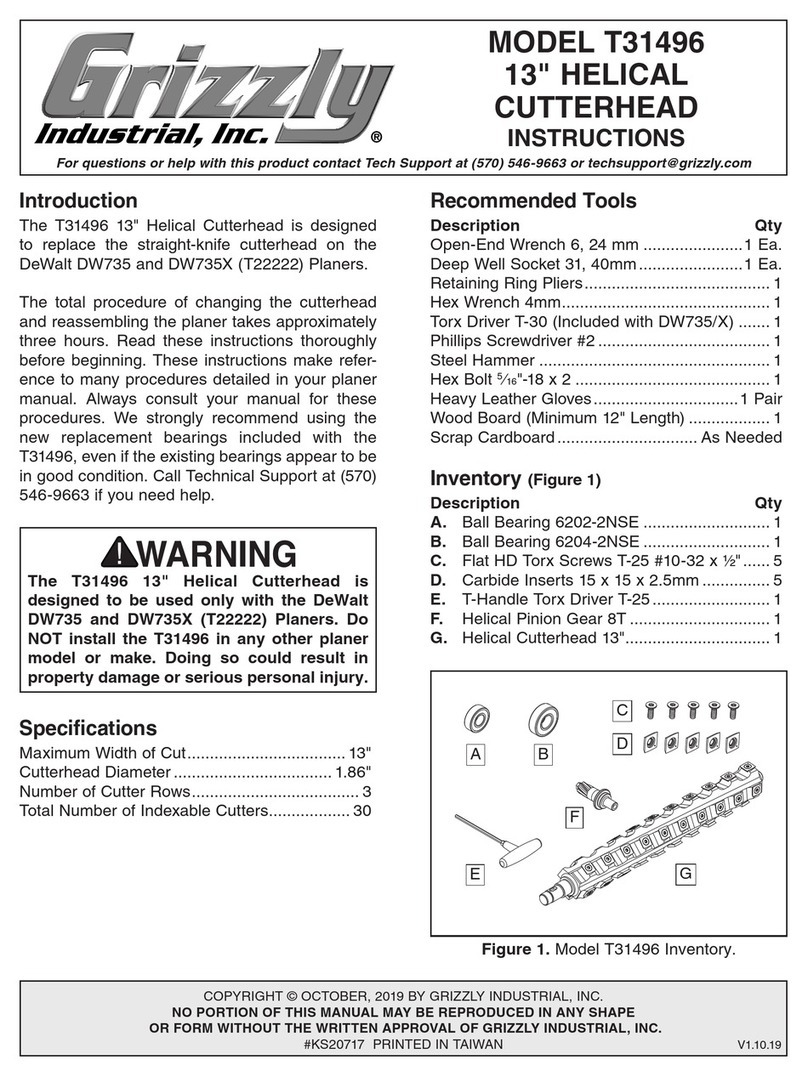

Figure 3. Wood Screw Placement.

Check the chuck for dust build-up in the scrolls

and jaws and clean as required.

To remove the jaws and backing jaws, the stop

pin will need to be removed from the slot of jaw

#4. By doing this, the jaws will be able to travel

beyond the scroll and then they can be pull out of

the slots.

To install jaws, first make sure you have jaw #1

going into slot #1 and so on, then turn scroll until

all jaws have engaged. Continue turning scroll

until the pin hole in slot #4 is visible and then rein-

sert the stop pin.

8mm hex wrench inserted into

this opening and then turn the

wrench to open/close the jaws.

Wood Screw

Standard Jaw

Backing Jaw