The G0857 and its com-

ponents are very heavy.

Get lifting help to move

heavy items.

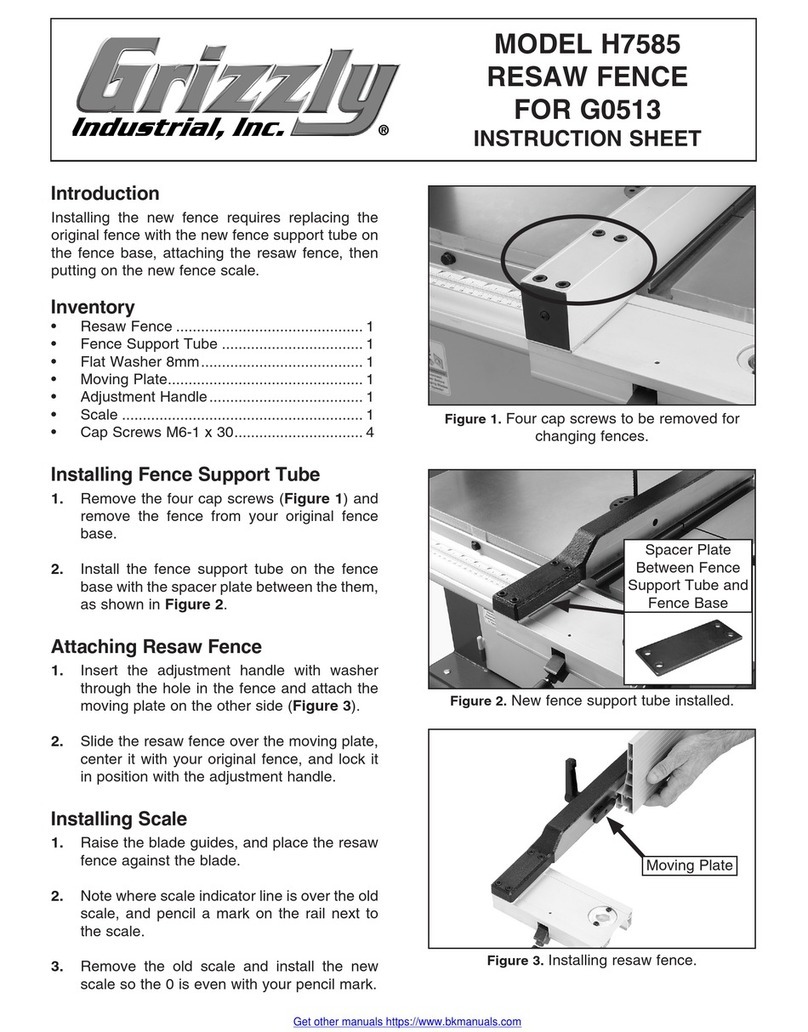

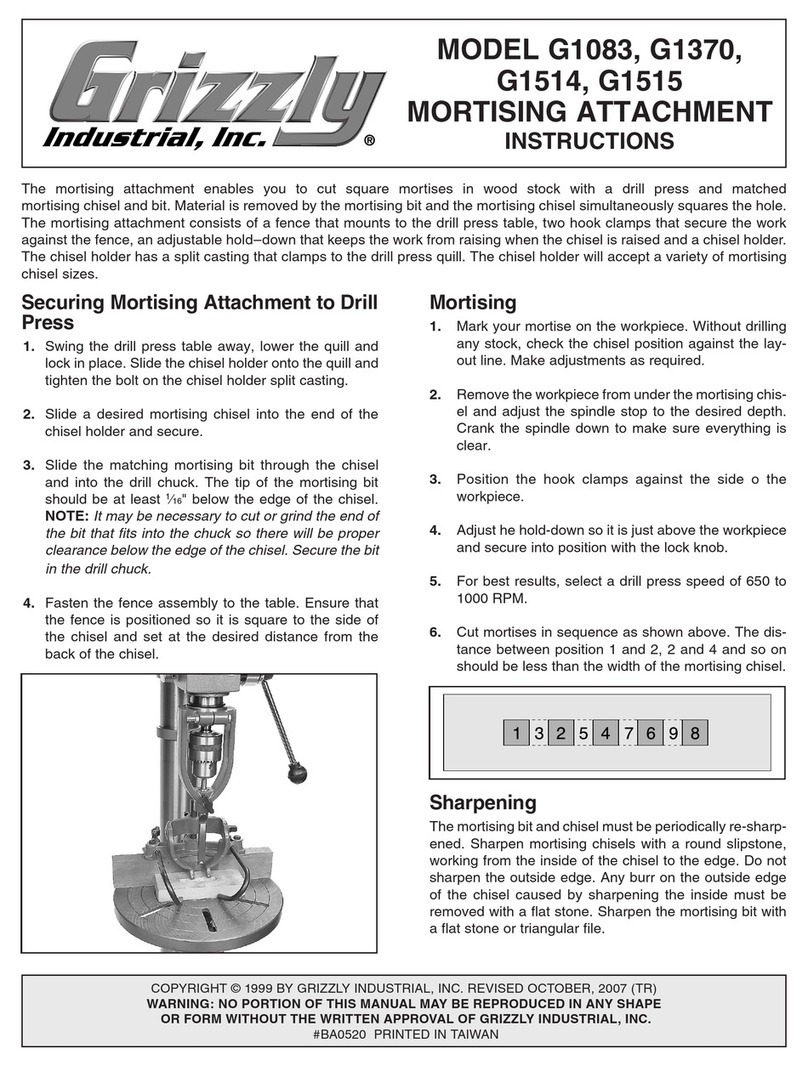

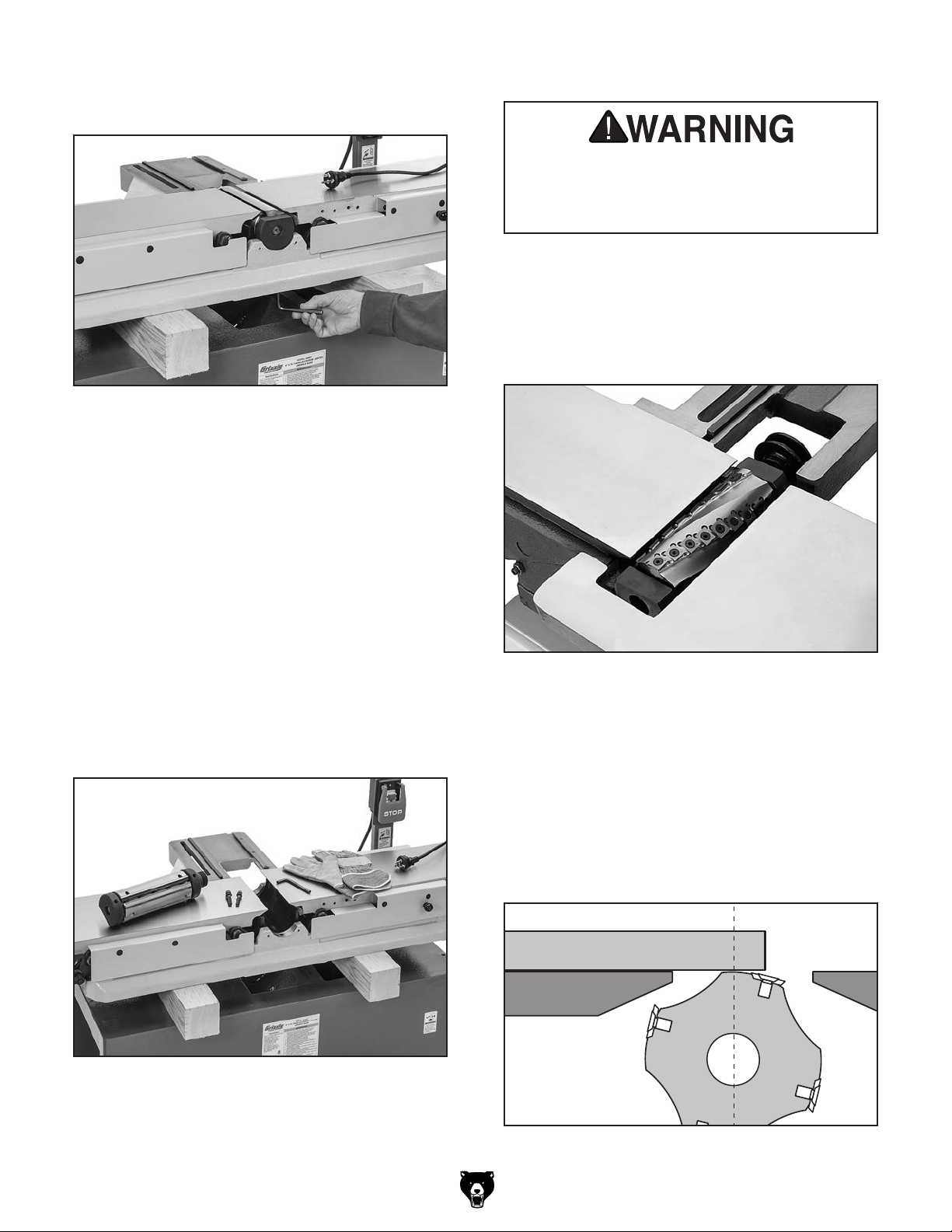

Figure 8. Cutterhead insert at top-dead-center.

Straightedge

Outfeed Infeed

-4- T32058 8" Helical Cutterhead Assembly

When correctly set, carbide insert will just

touch straightedge when insert is at its high-

est point of rotation (see Figure 8).

— If your outfeed table is correctly set, no

adjustments are necessary.

— If insert lifts straightedge off table or if

table is below straightedge, adjust outfeed

table height with outfeed table adjustment

lever until straightedge just touches an

insert at its highest point of rotation.

9. Tighten helical cutterhead in place, and

ensure pulley set screw is tight.

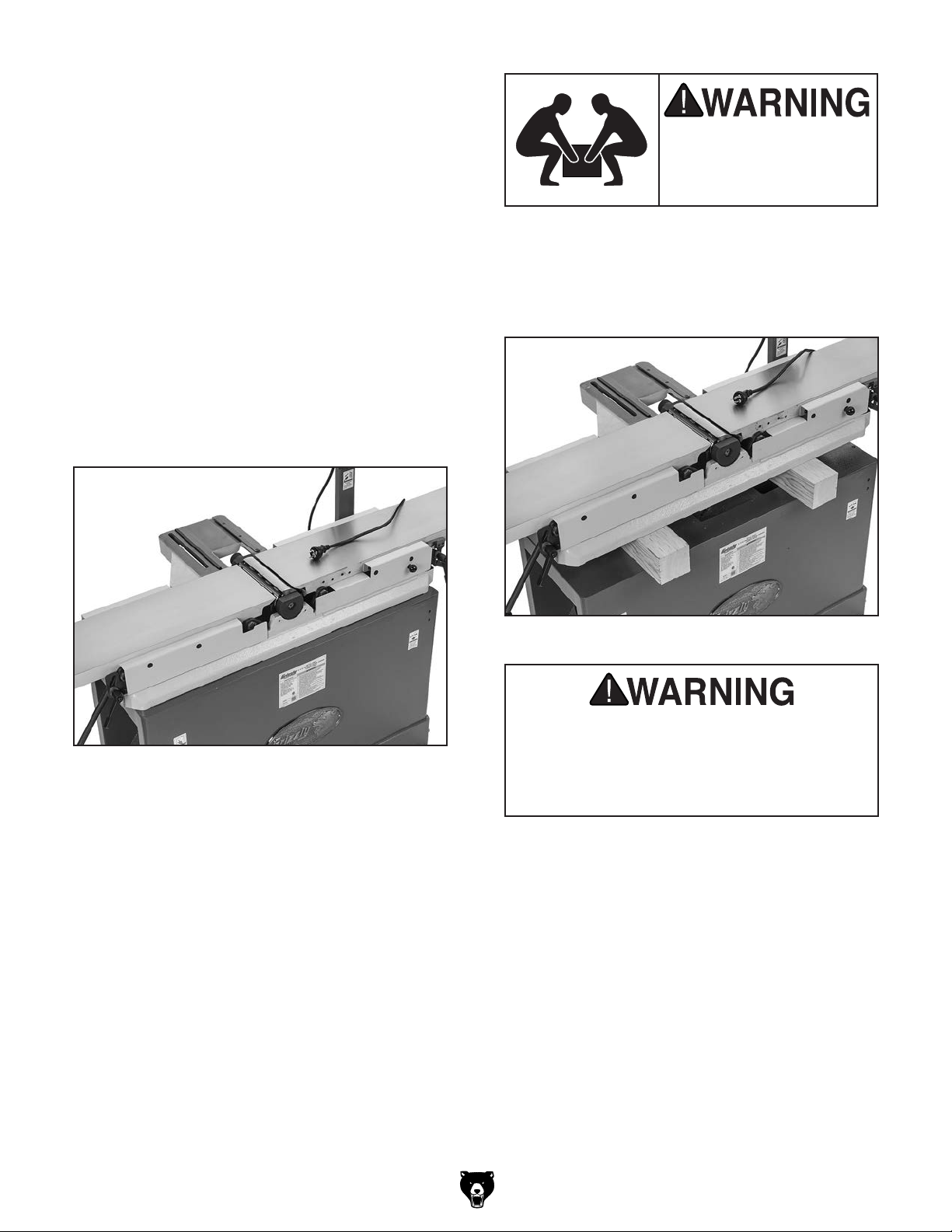

10. With help from an assistant, lift one side of

the table base and carefully remove one

wood block from underneath. Repeat for the

opposite side.

11. Secure jointer table base to cabinet stand

with (3) hex bolts, lock washers, and flat

washers removed earlier.

12. Lock outfeed table, then re-install fence.

13. Re-install V-belt on pulleys. (Refer to instruc-

tions in your G0857 manual for details.)

14. Re-install rabbeting table, cutterhead front

cover, rear access panel, and belt cover.

15. Reset positive stop bolts on infeed and

outfeed tables.

16. Install cutterhead guard back over cutterhead,

making sure that spring tension in guard

is properly set so guard springs back over

cutterhead when it is pulled back and

released.

5. Move straightedge to the other side to deter-

mine if one end of cutterhead body is higher/

lower than the other. (Place feeler gauge

between cutterhead body and straightedge to

determine the height difference.)

— If cutterhead is even or within 0.003" with

outfeed table from one side to other, skip

to Step 8.

— If cutterhead is over 0.003" from one side

to other, go to Step 6.

6. Loosen cap screws securing both bearing

blocks, lift helical cutterhead slightly, then

place a shim beneath bearing block that

needs to be adjusted.

Note: Use shims from your old cutterhead

if available. If not available, newspaper is

approximately 0.003" thick and will work for

shimming (we don't recommend shimming

more than 0.003" on either side, as this may

affect how the bearing block seats in the

casting).

7. Repeat Steps 4–6 and adjust as necessary,

then tighten cap screws on bearing blocks.

8. Place a straightedge on outfeed table

so it extends over cutterhead, and rotate

cutterhead pulley until one of the carbide

inserts is at top-dead-center (TDC), as shown

in Figure 8.