H7817 2000 lb. Electric Winch -1-

Safety Instructions for Electric Winches

1. READ THIS MANUAL: This manual

contains proper operating instructions

for this machine.

2. EYE PROTECTION: Always wear

ANSI approved eye protection when

operating winch.

3. LOOSE CLOTHING: DO NOT wear

loose clothing while operating this

machine. Keep hair, jewelry and

hands away from operating winch.

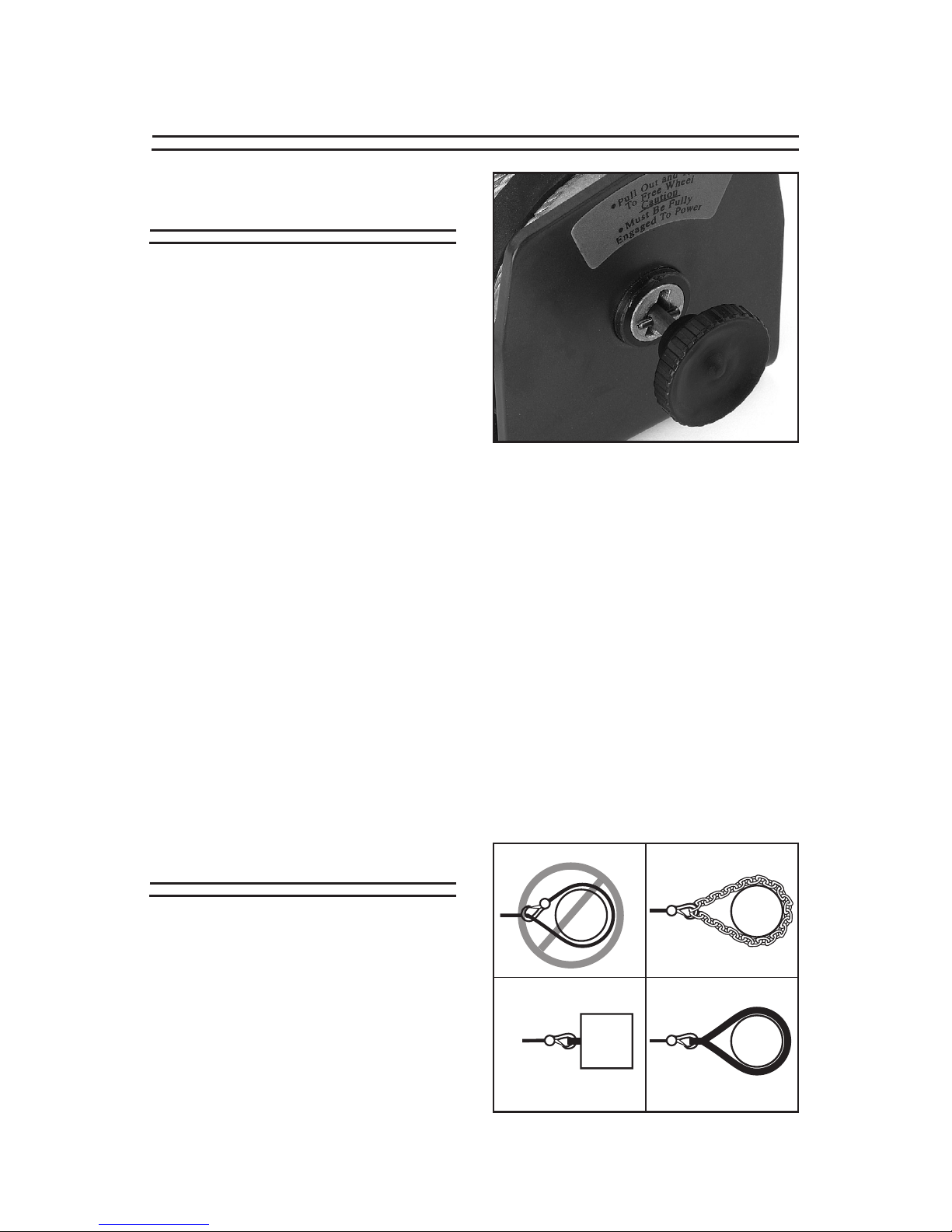

4. CABLE DAMAGE: Always inspect

any slings or pins and the cable for

frays, loose connections, or damage.

DO NOT use winch if any component

is damaged or if the cable is dam-

aged or frayed in any way.

5. CABLE REPLACEMENT: DO NOT

replace the cable with one of lesser

strength. A cable of lesser strength

could snap and whip back, causing

serious personal injury.

6. CABLE BREAKAGE: DO NOT stand

in line with or alongside the cable

while the winch is operating. If the

cable breaks it can whip back and

cause serious personal injury.

7. WINCH LIMITS: DO NOT attempt to

exceed the pulling limits of the winch.

Always leave a minimum of five turns

(1/2 wrap) of cable on the winch at all

times.

8. SAFETY SPOTTER: Use a spotter

to help ensure safety when using the

winch. Be sure the spotter is out of

the way of the vehicle and the cable

before operating the winch.

9. HAND ASSISTANCE: NEVER

attempt to assist the winch by pull-

ing on the cable while the winch is

running. This can cause serious per-

sonal injury.

10. AUTOMOTIVE BATTERY: Be sure

the battery is in good condition.

Always connect the positive (+/RED)

cable to the positive (+/RED) battery

post first, and then connect the nega-

tive (-/BLACK) cable to the vehicle

frame.

11. CABLE PROTECTION: Always pro-

tect the cable and any slings from

sharp edges. DO NOT stress the

cable or slings by using them on

extreme pulling angles.

12. VEHICLE SAFETY: NEVER acceler-

ate or reverse the winching vehicle in

order to assist in winching operations.

This can cause the winch or cable

to fail and cause serious personal

injury.