7 OM-AH/1E Domestic

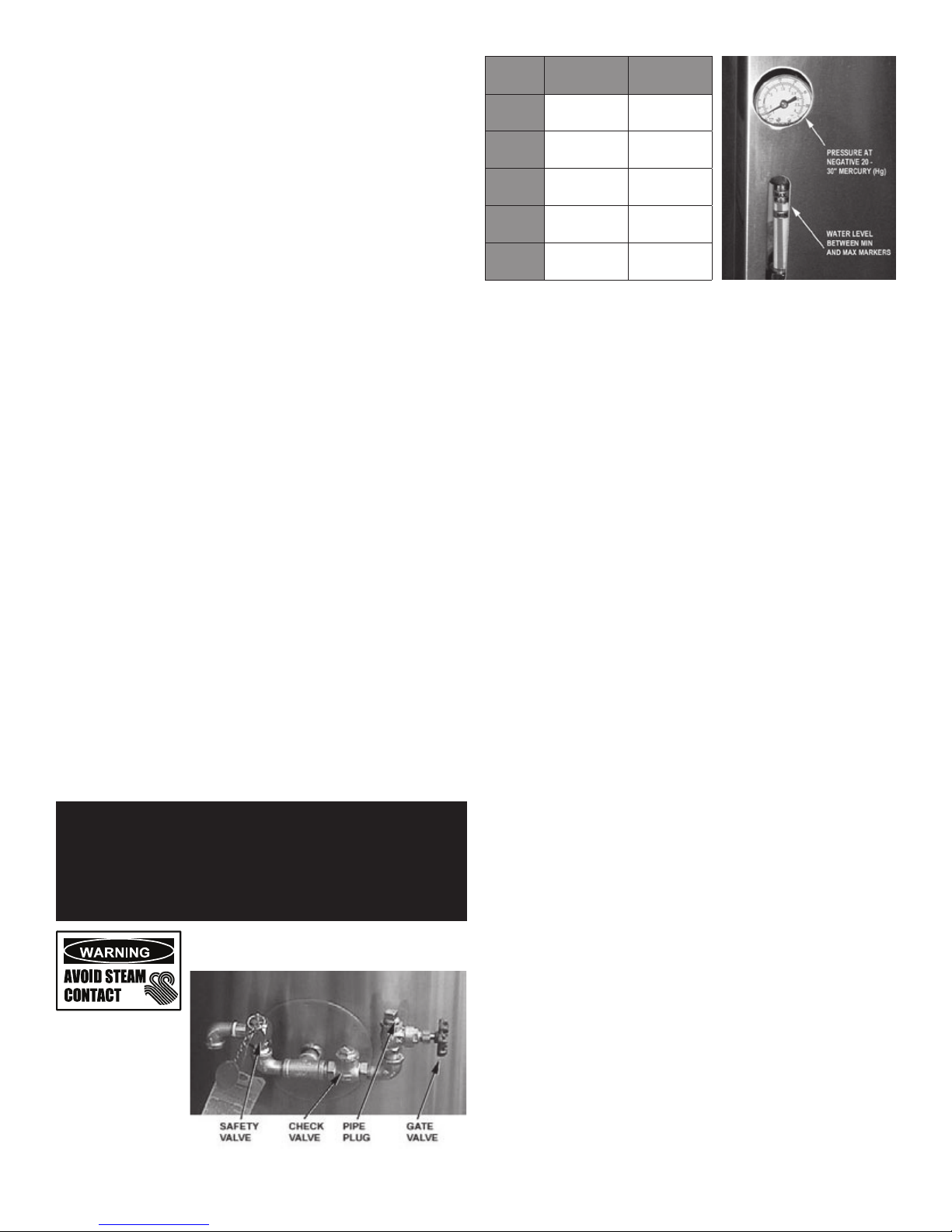

4. Check water level in the jacket to ensure that it is between minimum and

maximum marks on glass.

5. Close the valve and reinstall the square-head pipe plug.

6. Reestablish the jacket vacuum as described above. If the pressure gauge

does not show a negative reading of 20 to 30 inches mercury (Hg).

WATER TREATMENT

1.

Fill a mixing container with the amount of water required. Use only distilled water.

2. Following instructions apply to Water Treatment Kit.

a. Hang a strip of pH test paper on the rim of the container, with about 1 inch

of the strip below the surface of the water.

b. Stir the water continuously while you slowly add water treatment

compound until a color between indicating a pH of 10.5 and 11.5 is

reached. (Shown on the pH test kit chart.) Judge the pH by frequently

comparing the test strip with the color chart provided in the kit.

c. Use a measuring cup to add the compound so that you may record the

exact amount used.

d. The amount may be used again if the same water sources and compound

are used in the future. However, it is best to check the pH each time

treated water is prepared.

SEQUENCE OF OPERATION

The following “action-reaction” outline is provided to help understand how the

kettle works.

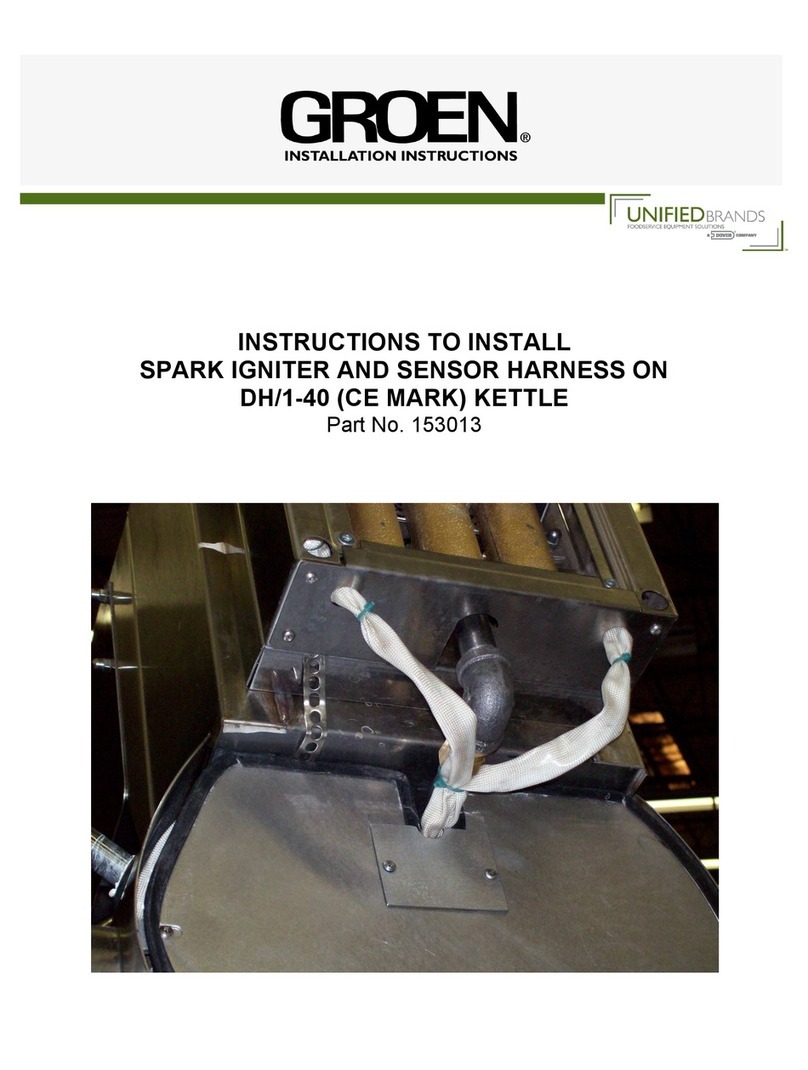

1. When the power switch is turned on, it starts the spark igniter and opens the

automatic valve for the pilot burner. The spark ignites a pilot flame, which

heats the sensor. The sensor then sends a signal to turn off the spark. The

flame thereafter acts as a standing pilot until the power is turned off.

2. If the pilot flame is not sensed within 90 seconds after spark begins, a timer

shuts down the entire operation. To attempt a second trial for ignition, turn

off the power switch. Check the gas supply valves and wait five minutes

before trying again by switching power on. If you cannot establish a pilot

flame in four tries, close all valves, turn off the power, and contact an

authorized Service Agency.

3. When the operator sets a temperature on the thermostat, it causes the

automatic valve to admit gas to the main burner, where it is ignited by the

pilot flame. When the kettle reaches the set temperature, the thermostat

switch opens. This stops the signal to the gas control valve and shuts off

gas to the main burner. The pilot flame stays lit.

4. When the kettle cools below the set temperature, the thermostat switch

closes and start another cycle. On and off cycling continues and maintains

the kettle at the desired temperature. This action is indicated by the Heat

Indicator light.

The kettle has the following safety features in addition to the 90-second ignition timer:

1. Low water cutoff relay that will shut off gas supplies to all burners until the

jacket water level is corrected.

2. High limit pressure switch, set to open at about 26 PSI and to shut down the

burners until jacket pressure is decreased.

3. Pressure relief safety valve, which will release steam if jacket pressure

exceeds 30 PSI.

4. Gas pressure regulator built into the gas control valve.

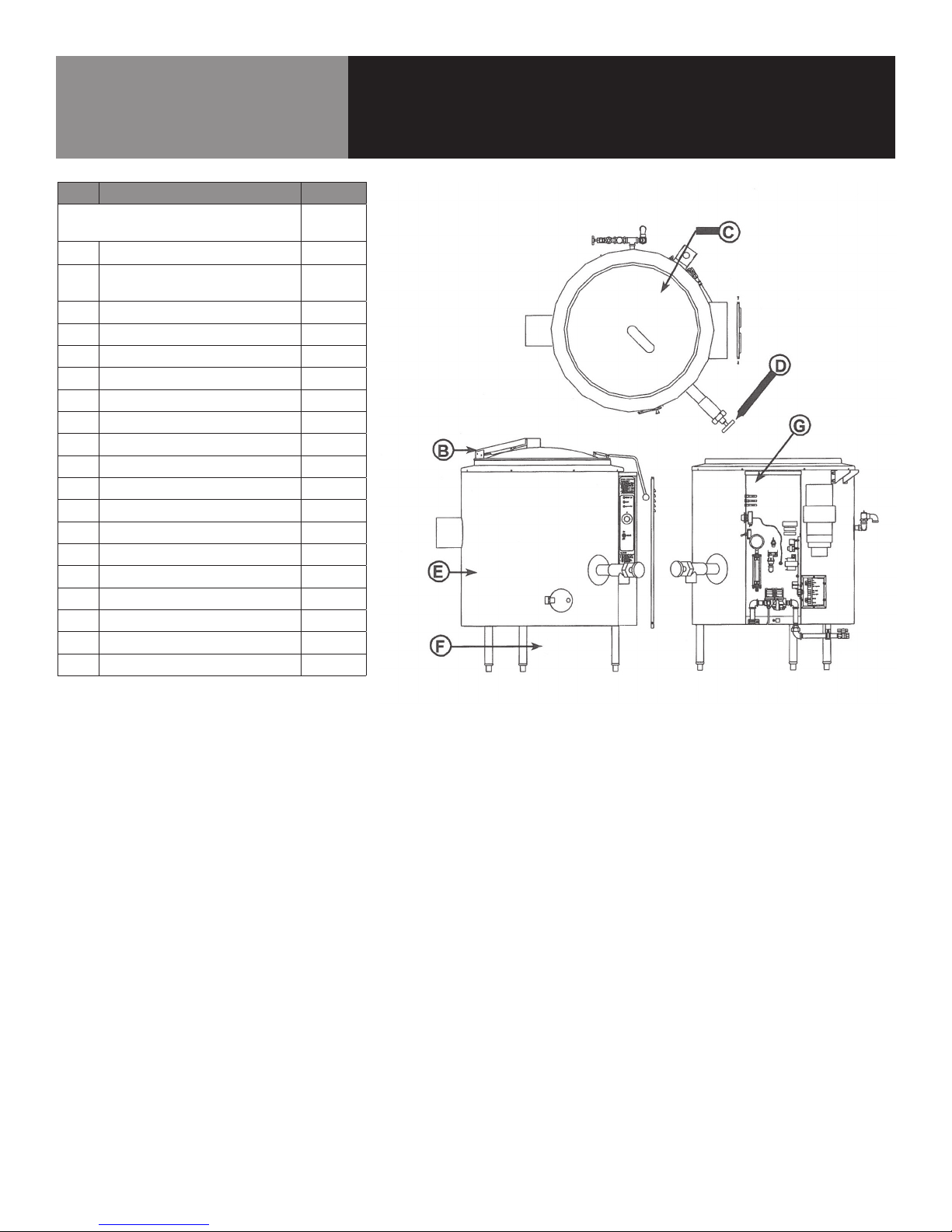

REPLACEMENT PARTS

To order parts, contact your Authorized Service Agent. Supply the model

designation, serial number, part description, part number, quantity, and when

applicable, voltage and phase.

CONTACT US

If you have questions pertaining to the content in this manual, contact Unified

Brands at 888-994-7636.

TROUBLESHOOTING

This unit is designed to operate smoothly and efficiently if properly maintained.

However, the following is a list of checks to make in the event of a problem.

Wiring diagrams are found at the end of this manual. When in doubt, turn unit

off and call for service at 888-994-7636. If an item on the check list is marked

with (X), it means that the work should be done by an Authorized Service Agent.

SYMPTOM WHO WHAT TO CHECK

Kettle continues

heating after

it reaches

the desired

temperature.

User a. Thermostat dial setting.

Auth Service

Rep Only

b. Thermostat calibration. X

c. Thermostat operation. The thermostat should click when

the dial is rotated above and below the setting for the

temperature of the kettle. X

Kettle stops

heating before

it reaches

the desired

temperature.

User a. Thermostat dial setting.

Auth Service

Rep Only

b. Thermostat calibration. X

c. Thermostat operation. Thermostat should click when

the dial is rotated above and below the setting for the

temperature of the kettle. X

Safety valve

pops open.

User a. For air in the jacket. See “Jacket Vacuum” in the

Maintenance section.

b. Thermostat dial setting.

Auth Service

Rep Only

c. For defective thermostat. The thermostat should click

when the dial is rotated to settings above and below the

temperature of the kettle. If defective, replace. X

d. For defective safety valve. If the valve pops at pressures

below 29 PSI, replace. X

Burners will not

light.

User a. That the main gas supply valve is open. (handle is in line

with the gas pipe).

b. Gas supply to the building.

Auth Service

Rep Only

c. Thermostat operation. The thermostat should click when the

dial is rotated to settings above and below the temperature

of the kettle. X

System does

not produce a

spark.

Auth Service

Rep Only

a. AC voltage between terminals on secondary side of

transformer with unit power turned on. If it is not 24 Volt,

replace the transformer. X

b. That the high tension cable is firmly attached and in good

condition. If cracked or brittle, replace. X

c. Pilot burner ceramic insulator for crack or break. X

d. Pilot spark gap. Regap. X

Pilot lights, but

main burner

will not come

on and spark

does not stay

on.

Auth Service

Rep Only

a. For 24 V between terminals MV and PV/MV while pilot is

burning. If 24V is not present, replace the ignition control

module. X

b. That gas pressure is at least 3.5” W.C.(8.7818 b). X

c. Electrical connections of the main valve to terminals, to

assure that they are securely attached. Check magnetic

operator for main valve on gas valve. Repair or replace as

necessary. X

Pilot lights, but

main burner

will not come

on, the spark

stays on.

Auth Service

Rep Only

a. Check for bad burner ground. If necessary, repair with high

temperature wire. X

b. Pilot burner ceramic insulator for cracks. X

c. That cable is not grounded out. If it is, correct the ground-

out condition or replace cable. X

d. For proper gas pressure. X

e. Clean pilot assembly, or replace if necessary. X

f. Tighten all mechanical and electrical connections. X

g. If the pilot flame is weak, increase pilot orifice size. X

h. Replace ignition control module. X

Main burner

comes on but

will not stay on.

Auth Service

Rep Only

a. Check burner ground for bad wire or connection. Replace if

necessary with high temperature wire. X

b. Check for low gas supply pressure. If necessary, replace

ignition control module. X

Spark is

present but the

pilot will not

light.

Auth Service

Rep Only

a. That the pilot valve is securely connected to terminals. X

b. For 24 VAC at terminals PV and PV/MV. If 24V is not present,

replace the ignition control module. X

b. That gas pressure is at least 3.5” W.C.(8.7818 b).

c. For gas at the pilot. If it is not flowing:

(1) Check the pilot gas line for kinks and obstructions. X

(2) Clean orifice, if necessary. X

(3) Check magnetic operator for pilot valve on gas valve.

Repair or replace as necessary. X

d. That the pilot spark gap is located in the pilot gas stream. If

not, adjust or replace the pilot burner. X

e. For drafts. Shield the pilot burner, if necessary. X