6 OM-EE-20 & 40 (CE) INTERNATIONAL

lever or ring for about 1 second. Repeat

this step, then let the pull ring or valve

lever snap back into the closed position.

WARNING

STAY AWAY FROM THE STEAM THAT IS

BLOWING OUT OF THE SAFETY VALVE.

THE STEAM CAN CAUSE A SEVERE

BURN.

3. Jacket Filling and Water Treatment

The jacket was charged at the factory with

the proper amount of treated water. You

may need to restore this water because it

was lost as steam during venting or by

draining.

a. If you are replacing water lost as steam,

use distilled water. If you are replacing

treated water that ran out of the jacket,

prepare more treated water as directed

in step 4, “Water Treatment Procedure.”

Do not use tap water.

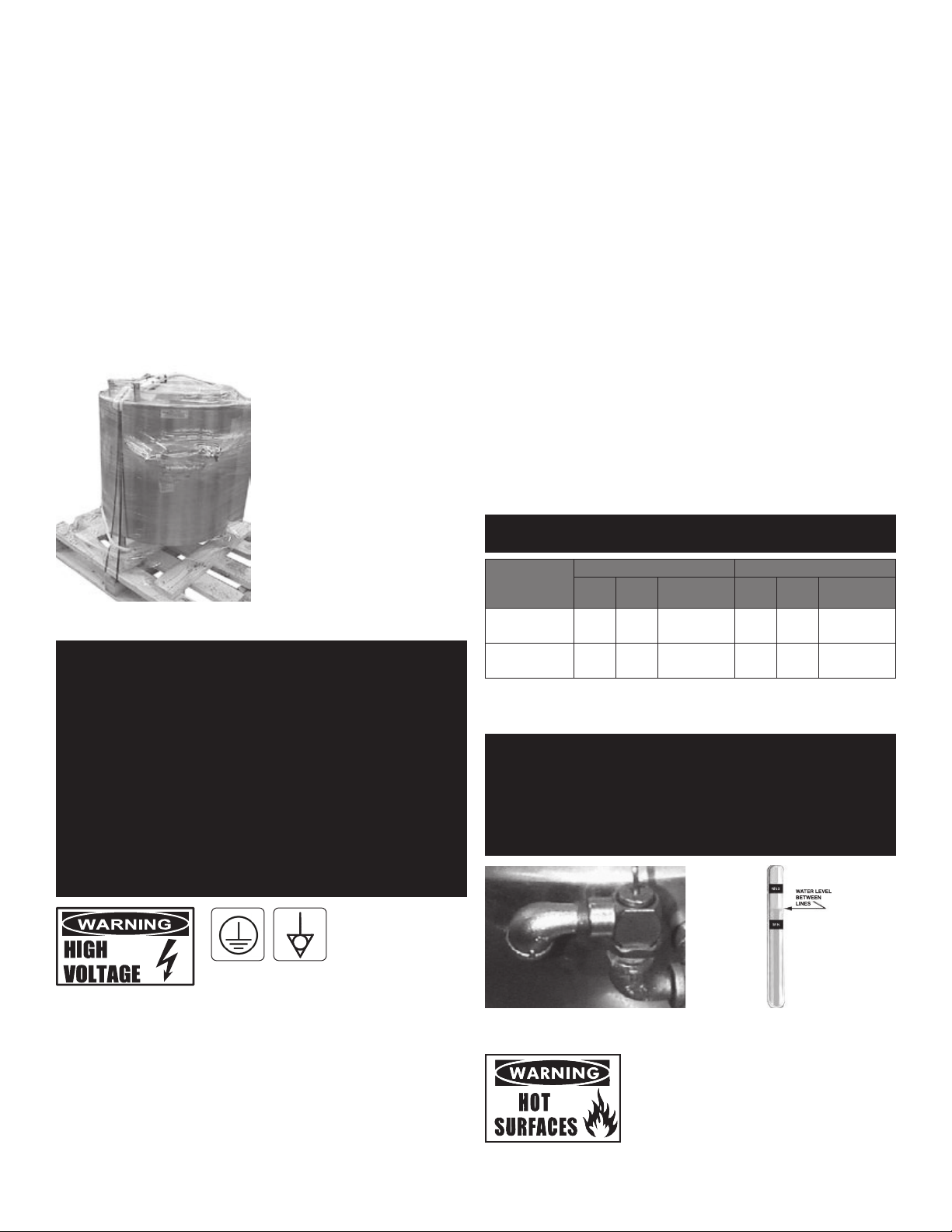

b. Allow the kettle to cool. Remove the

pipe plug from the jacket fill assembly.

c. Open the gate valve and pour in the

distilled or treated water.

d. Hold the safety valve open to allow air

to escape from the jacket while you

pour in the water. Continue to pour until

the water level rises to a point between

the marks on the gauge glass.

e. Close the gate valve and replace the

pipe plug.

f. Any air introduced into the jacket during

filling must be removed to obtain

efficient heating. See “Jacket Vacuum”

above.

4. Water Treatment Procedure

(1) Obtain water treatment compound and a

pH test kit from your Groen distributor.

WARNING

TO AVOID INJURY, READ AND FOLLOW

ALL PRECAUTIONS STATED ON THE

LABEL OF THE WATER TREATMENT

COMPOUND.

(2) Fill a mixing container with the

measured amount of water required.

(See table). Distilled water is

recommended.

Kettle Model Jacket Capacity

EE-20 3¼ Gallons

EE-30 4¼ Gallons

EE-40 5¼ Gallons

EE-60 7¼ Gallons

EE-80 10 Gallons

EE-100 10 Gallons

(3) Hang a strip of pH test paper on the rim

of the container, with about 1 inch of the

strip below the surface of the water.

(4) Measure the water treatment compound

(One way to do this is to add the

compound from a measuring cup.)

(5) Stir the water continuously, while you

slowly add water treatment compound,

until the water reaches a pH between

10.5 and 11.5. Judge the pH by

frequently comparing the test strip color

with the color chart provided in the pH

test kit. If you are color blind have a

person who is not color blind read the

test strip color level.

(6) Record the exact amounts of water and

treatment compound used. These

amounts may be used again, if the

same water sources and compound are

used in the future. However, it is best to

check the pH each time treated water is

prepared.

11

OM-EE

PERIODIC MAINTENANCE

NOTICE: Contact an authorized representative when repairs are required.

A Maintenance & Service Log is provided at the back of this manual. Each time

maintenance is performed on your kettle, enter the date on which the work was

done, what was done, and who did it. Keep this manual on file and available

for operators to use. Periodic inspection will minimize equipment down time and

increase the efficiency of operation. The following points should be checked:

[BY OPERATOR]

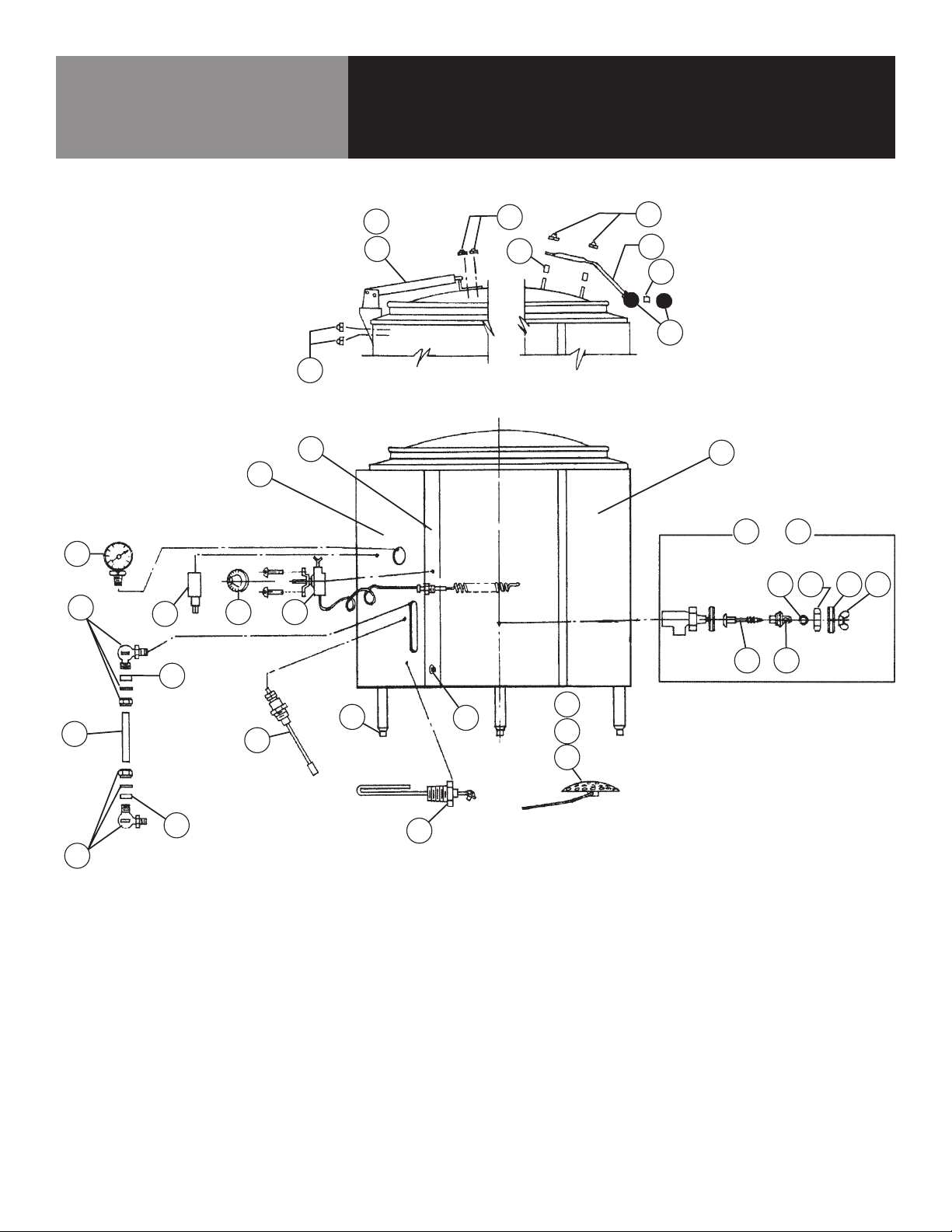

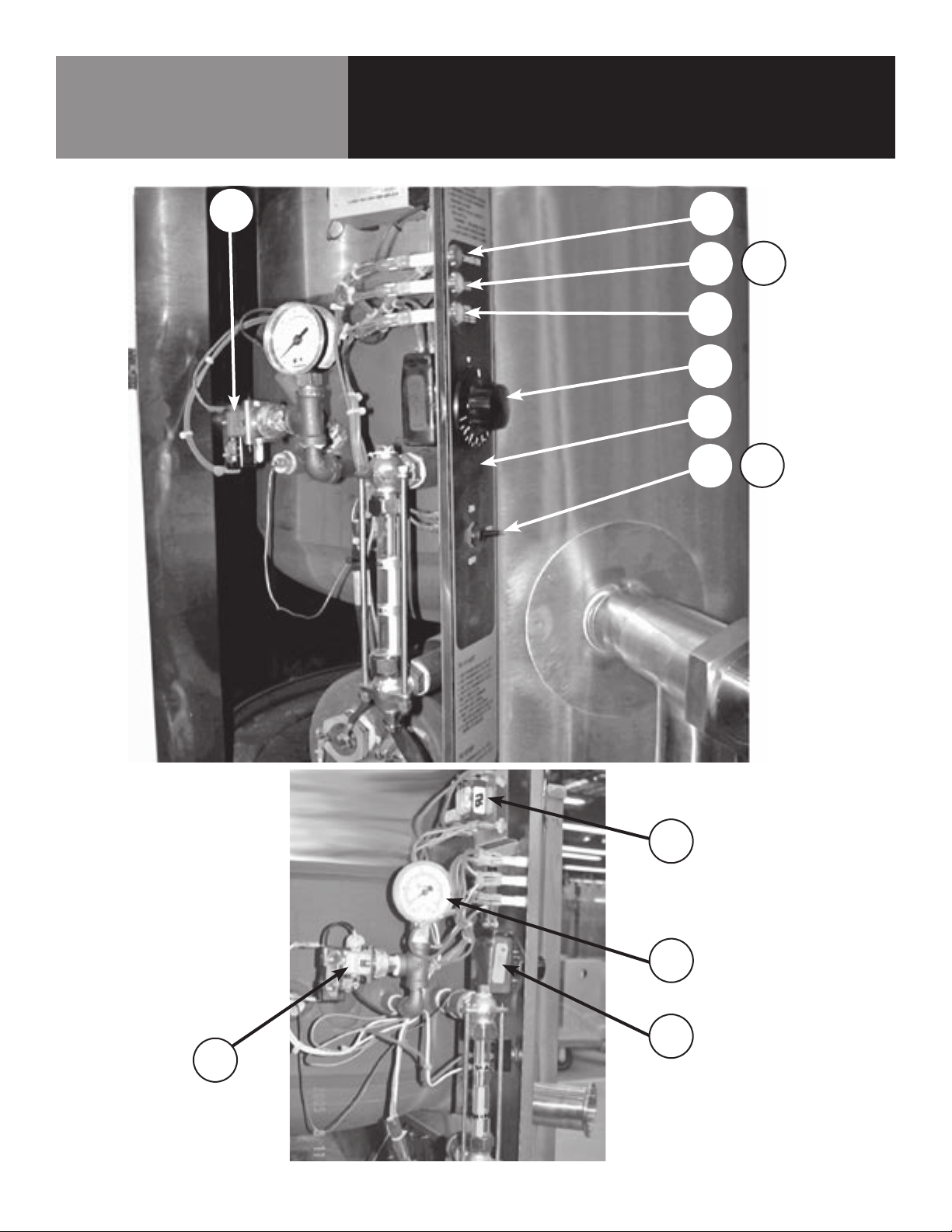

1. Check the pressure/vacuum gauge every day. The gauge should show a

vacuum of -20 to -30 inches of mercury (Hg) vacuum or a range of -0.7 to

-1.0 Bar, see “Jacket Vacuum” in this manual.

2. Also check the jacket water level every day. It should be between the marks

on the gauge glass. If the level is low, see “Jacket Filling and Water Treatment”

in this manual.

3. Carefully test the pressure relief valve at least twice each month. With the

kettle operating at 15 psi (105 kPa, 1.1 bar),pull the test lever and let it

snap back to its closed position. If there is little discharge (mostly air), and

the pressure gauge drops back to 0 psi (0 kPa, 0 bar), allow the pressure to

build back to 5 psi (35 kPa, 0.34 bar) and repeat the procedure. (Tip: Using a

screwdriver or other implement to pull the ring will help you avoid contact with

the steam.

[BY SERVICE TECHNICIAN]

4. Electrical wiring should be kept securely connected and in good condition.

5. The inside of the support housing should be kept clean.

6. The gear housing has fittings for lubrication of moving parts. The gears do not

run in oil, so periodic lubrication with grease is necessary.

7. Frequency of lubrication depends on operating conditions, but it should be

done at least once every six months.

8. Use a #2 grade LGI lithium grease to add grease through Zerk fittings on gear

housing until it flows out of the bearings around the trunnion shaft.

9. Place liberal amounts of grease on the gear to cover the arc that is in contact

with the worm gear.

10. Keep electrical wiring and connections in good condition.

11. Keep the inside of the control console clean and dry.

JACKET VACUUM/REMOVING AIR FROM JACKET

When the kettle is cold, a positive pressure reading on the pressure/vacuum gauge

or a reading near 0 psi (0 kPa, 0 bar) indicates that there is air in the jacket. Air in

the jacket acts as an insulator, and slows kettle heating.

To remove air:

1. Start the unit. (Be sure there is water or product in the kettle when heating).

2. When the pressure/vacuum gauge reaches a positive pressure reading of 5 psi

(35 kPa, 0.34 bar), release the trapped air and steam by pulling up the safety

valve ring for about five seconds. Repeat this step three or four times. Then let

the pull ring snap back into the closed position.

3. If there is little discharge (mostly air), and the pressure gauge drops back to 0

psi (0 kPa, 0 bar), allow the pressure to build back to 5 psi (35 kPa, 0.34 bar)

and repeat the procedure.

4. Once steam has been vented from the jacket as described in b, above, remove

the hot water from the kettle and replace it with cold. This will condense steam

in the kettle jacket, and the pressure gauge should show -20 to -30 inches

of mercury (Hg) vacuum or a range of -0.7 to -1.0 Bar. If it does not, or if the

vacuum is leaking down, contact an authorized service agency to correct the

problem.

PRESSURE RELIEF VALVE

At least twice a month, test the pressure relief valve. Test the valve with the kettle

operating at 15 PSI (105 kPa, 1.1 bar), by holding the test ring for at least five

seconds. Then release the ring and permit the valve to snap shut. If the ring does

not activate, if there is no discharge, or if the valve leaks, stop using the kettle

immediately and contact a authorized service representative.

JACKET FILLING

The jacket was charged at the factory with the proper amount of treated water.

You may need to restore this water, either because it was lost as venting steam or

by draining. If you are replacing water lost as steam, use distilled water. If you are

replacing treated water that ran out of the jacket, prepare more treated water as

directed in “Water Treatment Procedure,” below.

1. Allow the kettle to cool completely. The procedure will be easier with the kettle

under vacuum (pressure gauge reading below zero).

2. Allow the kettle to cool completely. Remove the pipe plug from the jacket fill

assembly. Pour in the distilled or treated water. Using a funnel will help you

in this process. Hold the pressure relief valve open while you pour, to let air

escape from the jacket. Continue adding water until the water level rises to the

center of the round sight glass.

3. Position a funnel in the opening and fill it with properly treated water.

4. Air that gets into the jacket during the filling operation must be removed,

because it will make heating less efficient. Follow the procedure in Jacket

Vacuum/Removing Air From Jacket above, to restore a negative pressure

reading.

WATER TREATMENT

1. Obtain water treatment compound and a pH test kit from your authorized parts

distributor.

2. Fill a mixing container with the measured amount of water required. (See

table). Distilled water is recommended.

Kettle Model Jacket Capacity

EE-20 3-1/4 Gallons (12.3 liters)

EE-40 4-1/2 Gallons (17.0 liters)

3. Hang a strip of pH test paper on the rim of the container, with about 1” (2.54

cm) of the strip below the surface of the water.

4. Measure the water treatment compound (ones way to do this is to add the

compound from a measuring cup).

5. Stir the water continuously, while you slowly add water treatment compound,

until the water reaches a pH between 10.5 and 11.5. Judge the pH by

frequently comparing the test strip color with the color chart provided in the pH

test kit. If you are color blind use an electroanalytical instrument to measure

the pH level or have a person who is not color blind read the test strip color

level.

6. Record the exact amounts of water and treatment compound used. These

amounts may be used again, if the same water sources and compound are

used in the future. However, it is best to check the pH each time treated water

is prepared.