8

Updated: 5/21/2003

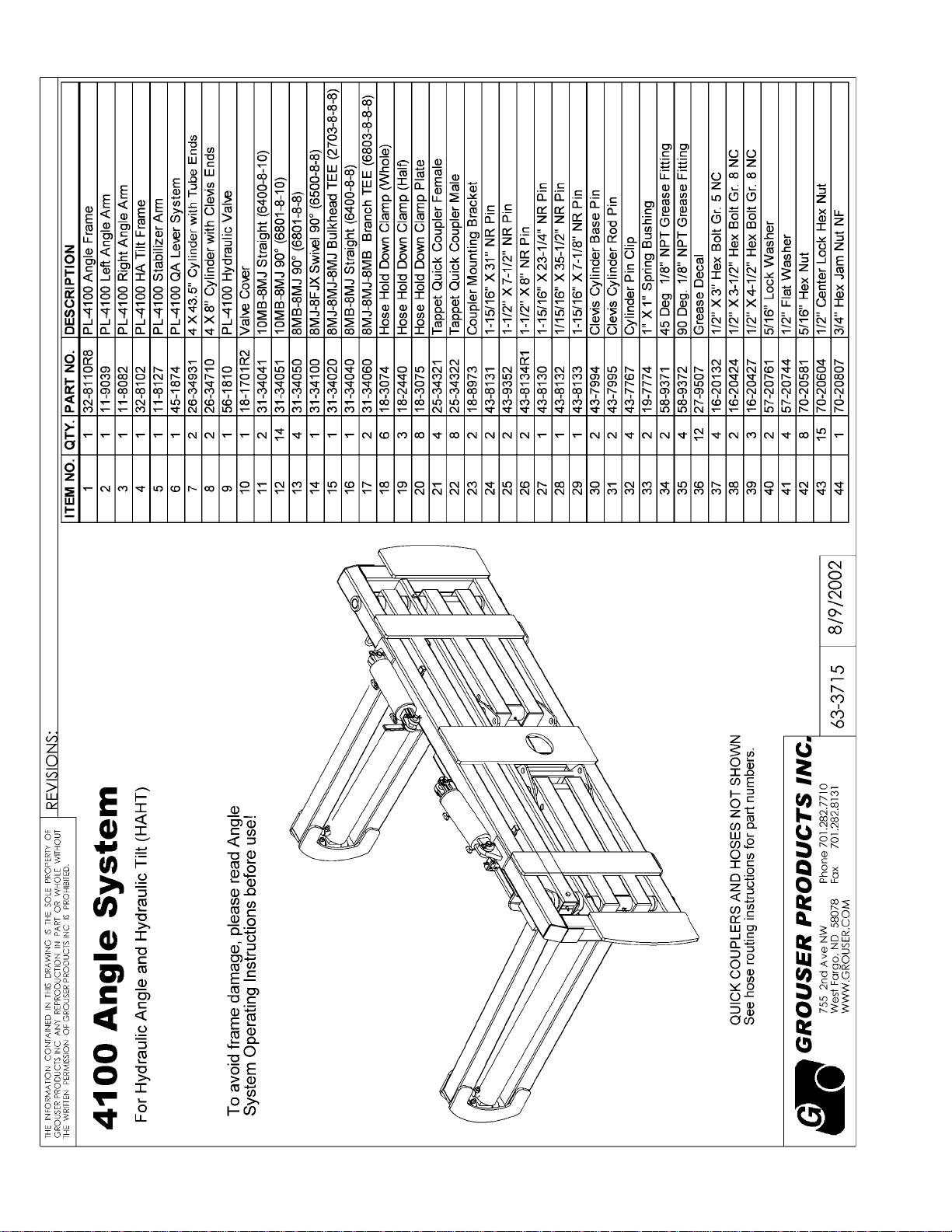

4100 H

YDRAULIC

A

NGLE

S

YSTEM

O

PERATING

I

NSTRUCTIONS

If your Grouser blade was purchased with the hydraulic angle option, you will have the ability

to angle the blade 30 degrees left or right. To achieve these angles the two cylinders are designed

to operate independently of each other through an electric diverter valve. To angle the blade to

the left, actuate the tractor hydraulic control lever in the cab with the diverter valve un-powered.

To angle the blade to the right, apply power to the diverter valve and then actuate the tractor hy-

draulic control lever.

The diverter valve has a built-in safety relief valve that allows the cylinder to retract if its inter-

nal pressure exceeds 2000 psi. With this safety feature in place, when either cylinder reaches the

end of its stroke, the safety relief valve will reroute pressure to the opposite cylinder causing it to

extend. While the factory setting on the relief valve is high enough to maintain an angle setting

under full load, this may be cumbersome to some operators, the following are possible adjust-

ments to this remedy this action:

Reduce tractor valve pressure: Some newer tractors allow the service valve pressure to be ad-

justed below the 2000 psi point of the safety relief valve.

Set the safety relief valve at a higher pressure than tractor: To increase the pressure of

the relief valve install a 0-5,000 psi pressure gauge into base end of right angle cylinder (see pg

20). Loosen the jam nut on the safety valve and tighten the Allen screw ½ turn. Now extend the

right side cylinder out until the safety valve activates, while the safety valve is in function, record

the pressure reading on the gauge. Continue to tighten the Allen screw in ½ turn increments and

record the pressure until a high enough relief setting is obtained. Do not exceed the 3000-psi

operating pressure of the cylinders. Tighten jam nut and remove gauge.

Automatic lever release: In some newer tractors the hydraulic control lever will automatically

release and instantly stop oil flow once the end of the stroke is reached.

CAUTION: Do not bypass the safety relief valve and plumb each cylinder to separate

valves on the tractor.

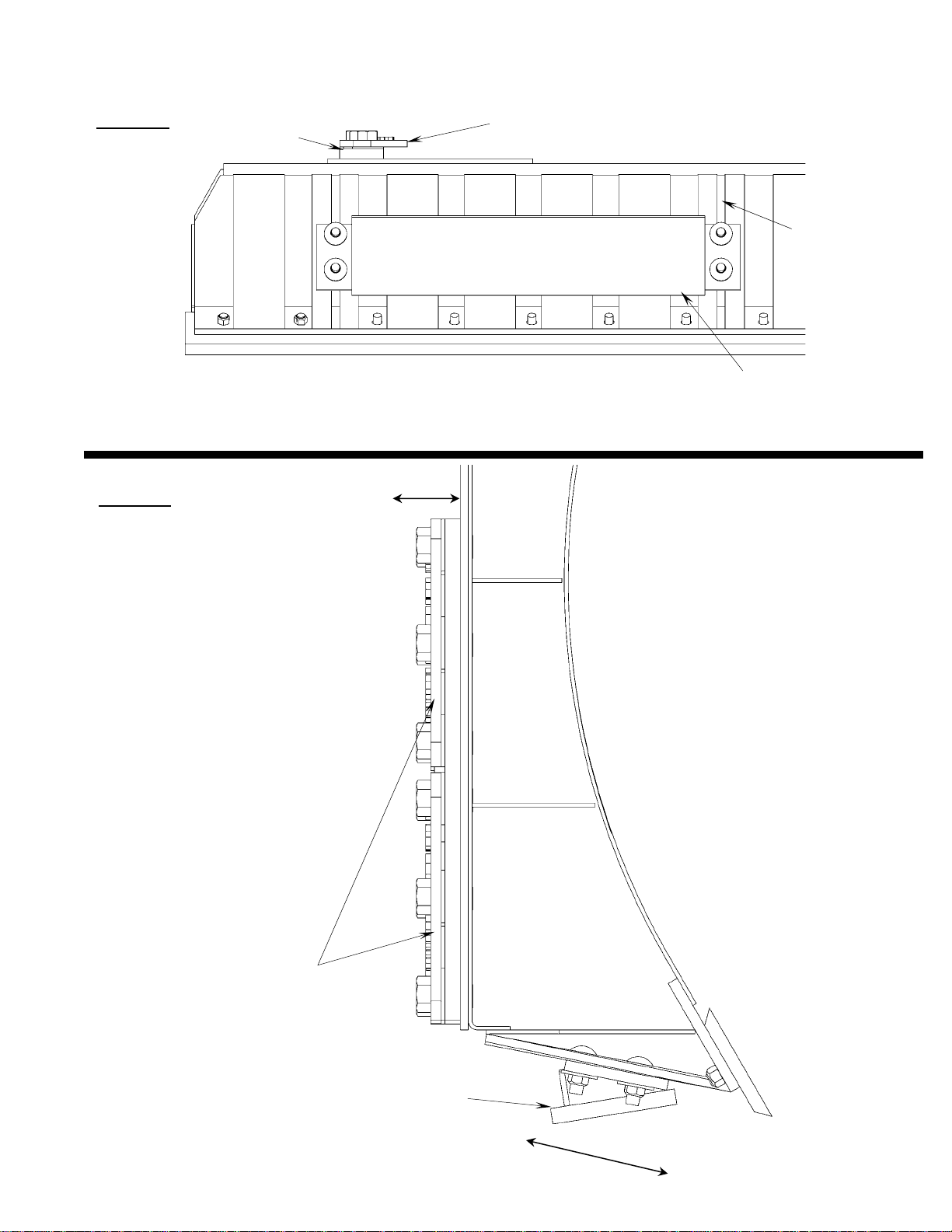

To ensure proper use and life of equipment, it is recommended to have both cylinders closed for

straight ahead dozing and only one cylinder partially or fully extended for angled dozing as shown

in the diagrams below. If the angle system is not used correctly, frame damage may oc-

cur. Some damaged frames can be repaired, please contact Grouser Products for repair instruc-

tions if needed.

Please contact Grouser Products with any questions by:

Phone- 701-282-7710 or 800-747-6182; Fax- 701-282-8131