12.09.2007

2 3 112 249 en Correction sheet

GMK truck cranes

Suspension struts – check oil level

Spare parts and

tools

– Press with connected hose (from tool box)

Prerequisites – The engine is not running and is secured against unauthorised use.

– Immediately before the inspection, the truck crane was completely

lowered and returned to On-road level; àOperating Instructions.

Checking the

oil level

Use only oil as specified in the maintenance plan M1; àp. 1.

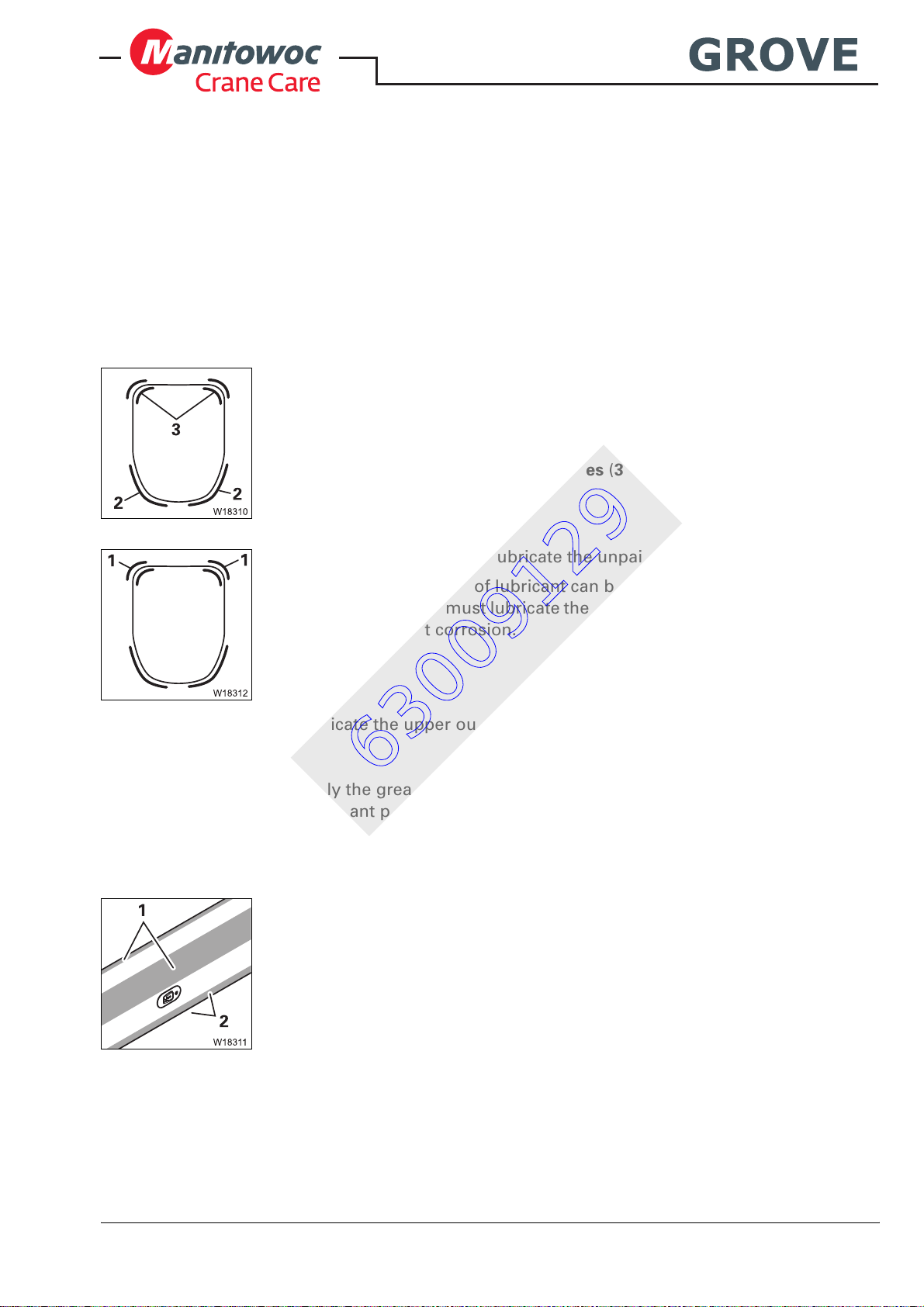

•Check whether oil is visible in the middle of

the inspection glass (1) on each suspension

strut.

If the oil level is too low:

•Open the connection (2) – oil escapes – and

quickly connect the press with hose.

•Inject oil up the centre of the inspection

glass.

•Remove the hose and quickly close the

connection (2).

SRisk of damage due to faulty suspension struts

If the oil level is above the upper marking on the inspection glass the

suspension strut is faulty and must be replaced.

Notify an authorised GROVE dealer or CraneCARE.

SRisk of damage to the suspension struts due to insufficient lubrication

It is difficult to inject the oil. Even so, do not fill oil through the inspection

glass connections. If you do this, the oil will not reach all the lubricating

points.

63009129