3

Calibration procedure

1. Vent the air from pump, pipelines and meter by dispensing until the flow stream is full and steady.

2. Stop the flow by shutting off the nozzle, but let the pump run.

3. Reset the Batch Total to zero using reset knob (3).

4. Dispense at the desired flow rate into a graduated container whose capacity should not be lower than 20 litres (5 gallons).

5. The Meter Value should be matched with the Container Value as given below.

• If the Meter Value is higher than Container Value (i.e the meter is running fast), loosen the Calibration screw (16) anticlockwise.

• If the Meter Value is lower than the Container Value (i.e the meter is running slow), tighten the Calibration screw (16) clockwise.

6. Repeat steps (3 - 5) until accuracy is satisfactory.

Note

Do not reduce the flow in order to reach a preset value of the calibration container.

The right method is to start and stop the full flow repeatedly until the required level is obtained.

Notes

• Longer pipes or nozzles reduce the flow by causing higher pressure losses.

• Use By Gravity is not recommended where the height of fuel is lower than 4 feet as the flow rate will be reduced, resulting

in inaccurate measurement. For better accuracy, ensure that the flow rate never falls below 20 LPM (5 GPM).

• On field calibration is always recommended in case of Gravity installations.

Note

Always fix the

Calibration Screw (16)

with O Ring (15) to

avoid leakage.

The meter is pre-calibrated in factory under standard conditions.

A new calibration is necessary whenever there is a change in any

of the following:

• Media Viscosity OR

• Flow Rate OR

• Operating Temperature

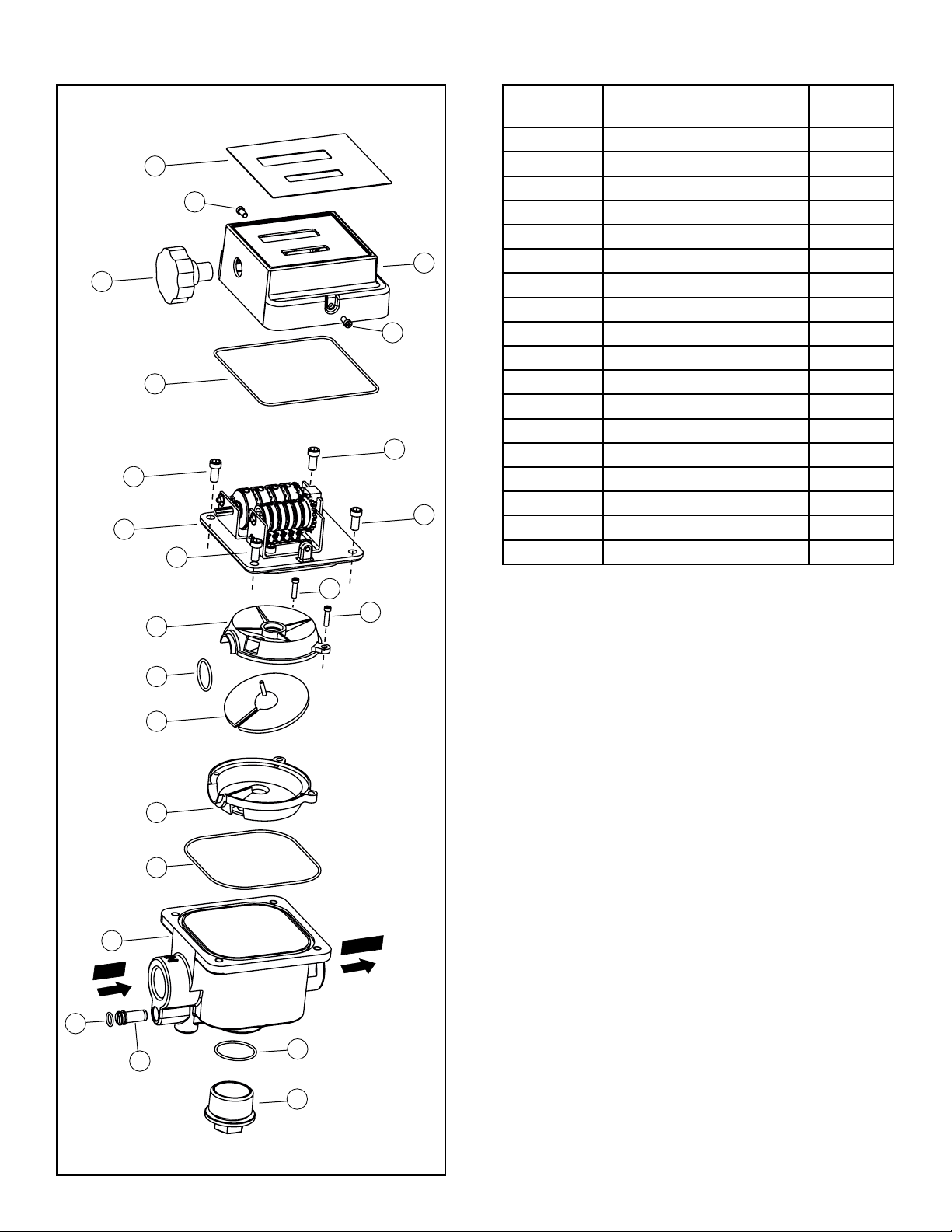

METER CALIBRATION (Refer to Exploded View - Page 5 )

After installation, turn the reset knob (2) until the batch total becomes zero. The totalizer cannot be reset in any way.

Use by Gravity

This meter can also be used without pump pressure in a system where flow is generated due to difference in height between fuel level and

dispensing point.

Notes

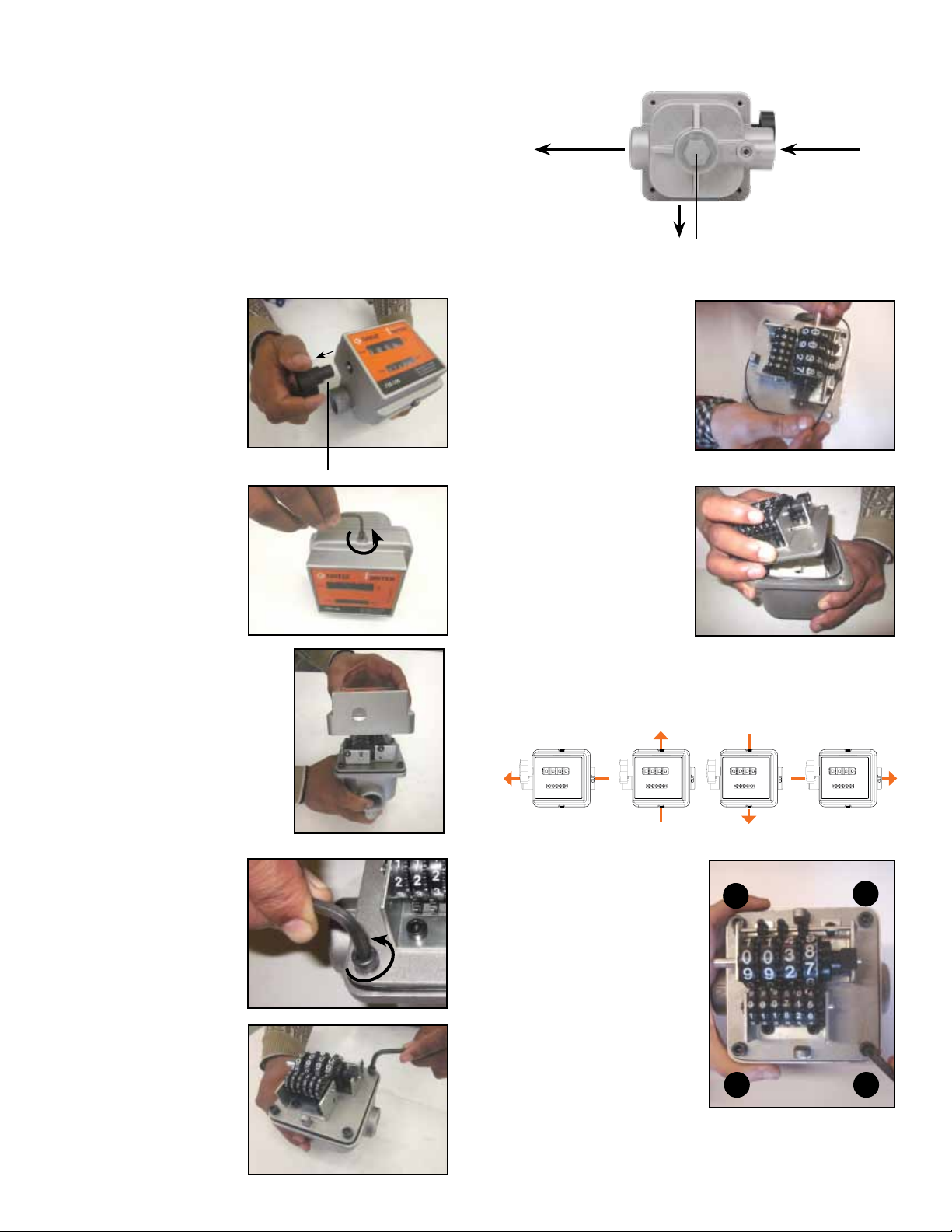

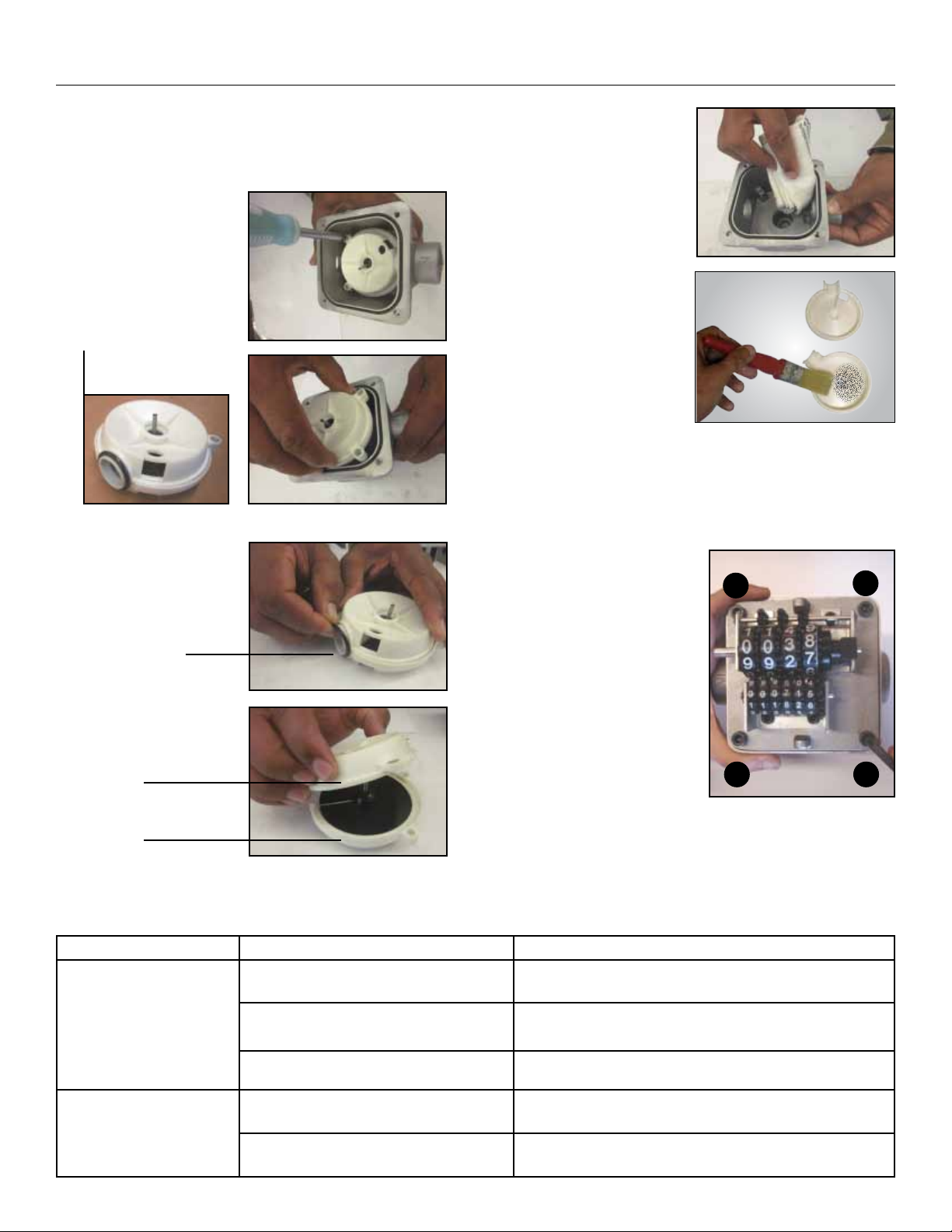

• The meter can be easily disassembled into its main parts without removing the meter from the pipes.

• Never remove meter label from the meter.

• Internal parts should be cleaned with a soft brush or small tool (i.e. a screwdriver).

• During cleaning, be careful not to damage the measuring chamber or nutating disk.

• A new calibration is always necessary after disassembling the measuring chamber. Before disassembling always ensure

that the line pressure is released and all fluid is drained from the meter.

Container Value

Meter Value

OPERATION (Refer to Exploded View - Page 5)

MAINTENANCE (Refer to Exploded View - Page 5)

This fuel meter does not require any special maintenance other than the cleaning of measuring chamber (It may get clogged sometimes due to

insufficient filtration).

98

0 2 2 2 2 2

0 0

Important

For ensuring the accuracy of measurements, the flow

rate should never be kept below 20 LPM (5 GPM).