5

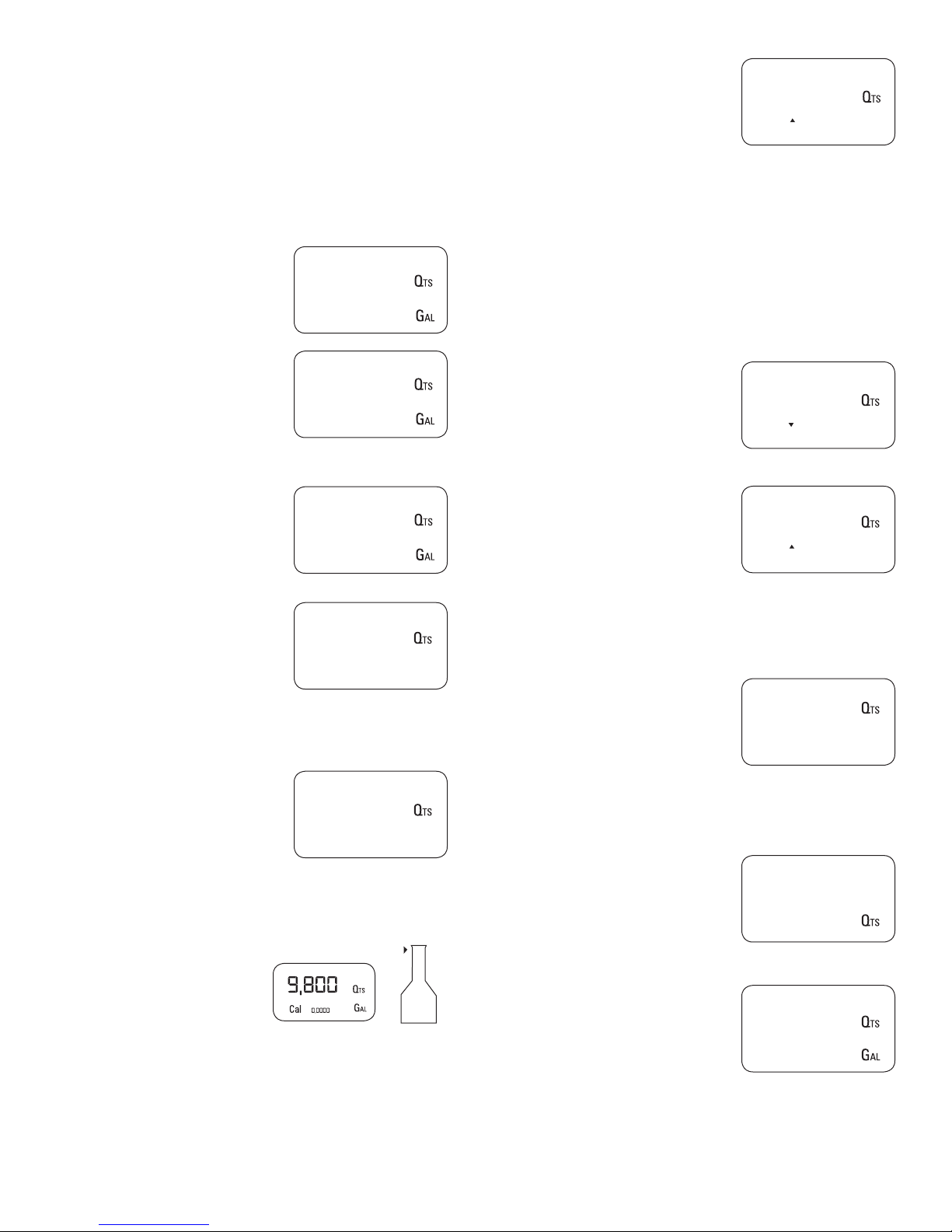

D. NORMAL DISPENSING MODE

While the media is flowing through the meter, Batch Total and

Reset Total are displayed at the same time.

A few seconds after dispensing has ended, on the lower Total,

the display switches from Reset Total to General Total: the word

RESET above the word TOTAL disappears, and the Reset Total is

replaced by the General Total.

This situation , where only “TOTAL” is displayed, is called

STANDBY mode. It remains stable until the user operates the

meter again.

12.3 Reset

TOTAL

12.3 TOTAL

4. Press CAL key for more than

2 seconds to store the new

settings. The METER will pass

through the start cycle and

come back to the Stand by

Mode.No new calibration is

required after changing the

Unit of Measurement.

L

L

12,345

2342,3TOTAL

1. While in standby (i.e when the display shows TOTAL), press

the RESET button.

2. During reset, the display screen first of all shows all the lit-up

digits and then all the switched off digits.

3. At the end of the process, a display page is first of all shown

with the reset batch and the Reset TOTAL

4. After a few moments, the Reset TOTAL is replaced by TOTAL.

F. RESETTING THE RESET TOTAL

The Reset Total can be reset by pressing the RESET key at length

while the display screen shows Reset TOTAL. The steps to be

taken are:

1. Wait untill the display shows Total only (standby mode)

2. Press the RESET key quickly.

3. The meter starts to reset the Batch Total.

4. While the display page showing the Reset Total is displayed,

press the Reset key again for at least 1 second.

E. RESETTING THE BATCH TOTAL

5. The display screen again shows all the segments of the

display followed by all the switched-off segments and finally

shows the display page where the new Reset Total is shown.

G. DISPENSING WITH FLOW RATE MODE DISPLAY

1. In standby mode, press the CAL key and start dispensing the

media.

2. The display will start showing “FLOW RATE”, in place of

TOTAL.

3. To return to standby mode, stop dispensing & when the flow

rate becomes zero, press CAL key once again.

H. CALIBRATION

In standby mode, press the CAL key for more than 2 seconds to

see the current calibration factor.

• Factory K Factor: Factory-set default factor.

It is equal to 1 (indicated as 1,000).

• User K Factor: Customized calibration factor,

meaning modified by calibration.

The meter has been calibrated at the factory under the following

operating conditions:

Fluid : Diesel fuel

Temperature : 20°C (68° F)

Flow rate : 50 LPM (13 GPM)

Calibration is needed to make the meter suitable for actual

conditions.

I. CALIBRATION PROCEDURES

1. In-Field Calibration

2. Direct Calibration

By pressing the CAL key while the meter is in Standby, the display

shows the current calibration factor used. Two cases can occur:

CASE 1:

If no calibration has ever been performed, or the factory setting

has been restored after previous calibrations, the following display

page will appear:

The word “Fact” abbreviation for “factory” shows that the

factory calibration factor is being used.

CASE 2:

If, on the other hand, calibrations have been made by the

user, the display page will appear showing the currently used

calibration factor ( in our example 0,998) .

1,000

Cal FACT

0,998

Cal USER

12,345

12,345