www.groz-tools.com

2

WARNING

Do not use the meter without a fuel filter installed before the

meter.

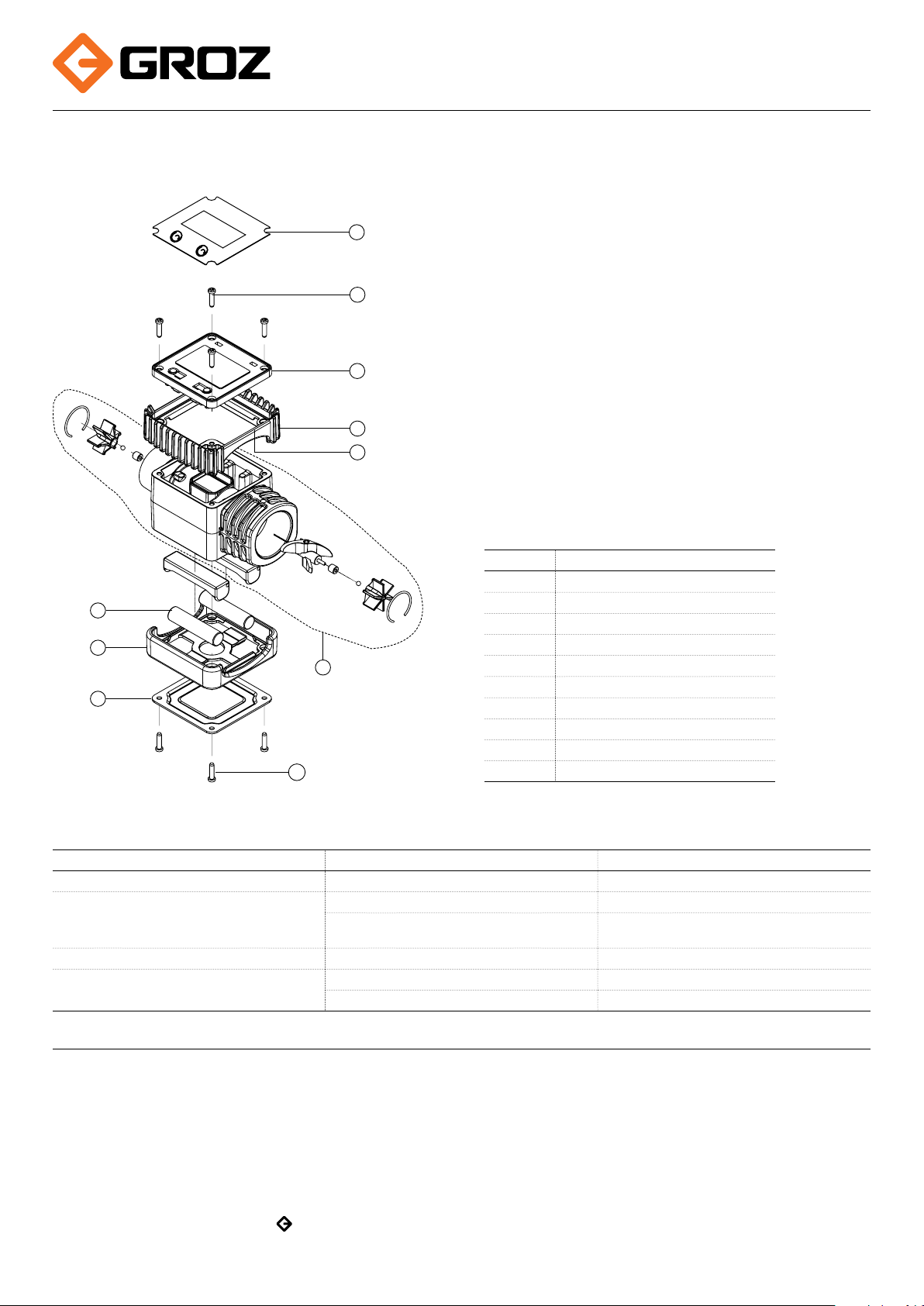

INSTALLATION (REFER “EXPLODED VIEW” ON PAGE 6)

This is a bi-directional meter with 1” threaded male & female ports.

The meter can be installed in any position - fixed in line or mobile on

a control nozzle.

1. Remove the four screws (2) and separate the card housing (5)

from the turbine assembly (6).

2. Rotate the card housing in any of the four positions as shown in

the picture and tighten the card housing with four screws (2)

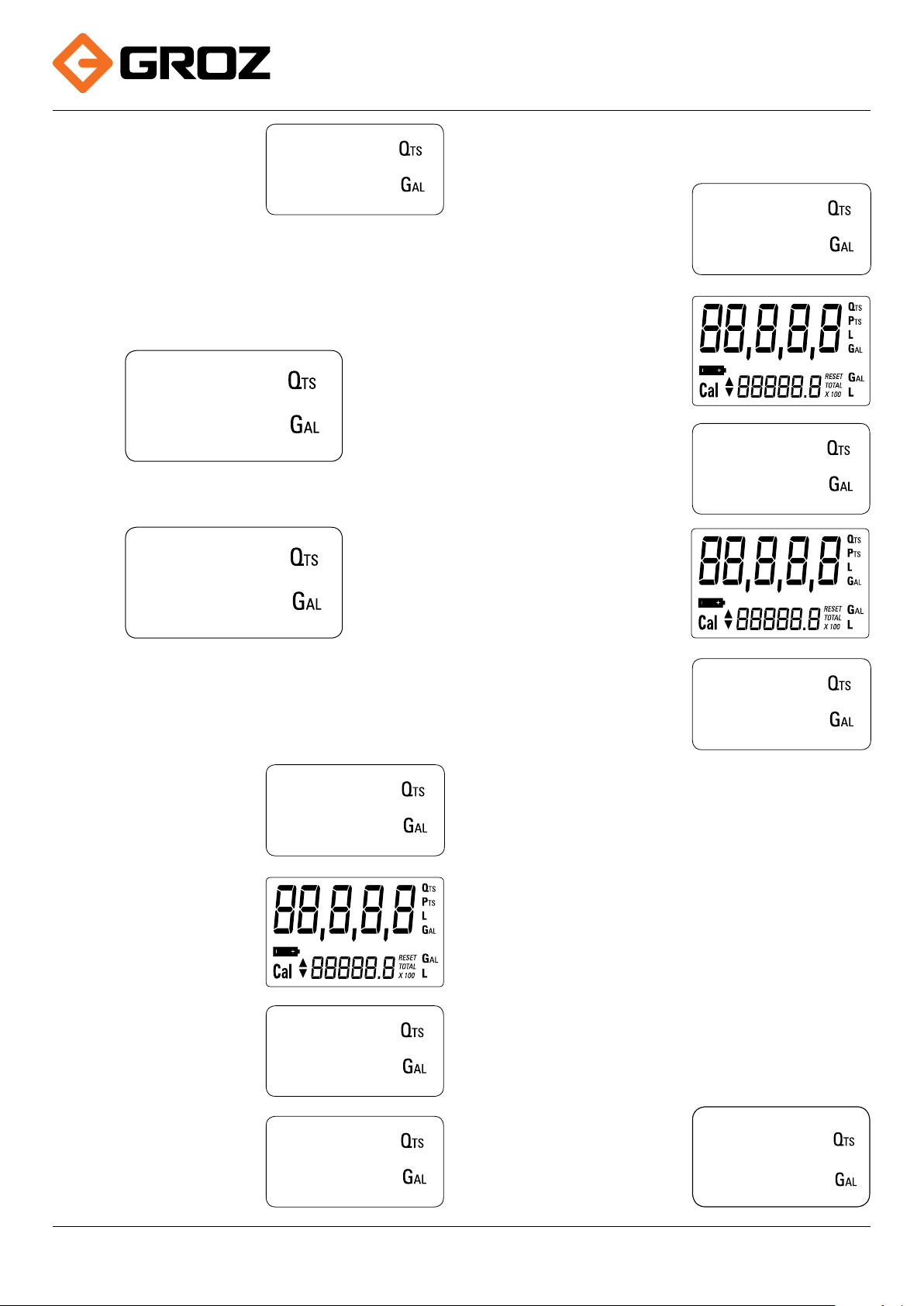

LCD DISPLAY: Powered by two alkaline batteries of 1.5 V each.

Includes three numerical TOTALs and other keys as given below:

1. Resettable Batch TOTAL (5 digits with moving comma):

indicates volume dispensed after RESET button was last

pressed.

2. Indication of battery charge.

3. Indication of calibration mode.

4. Totalizer (6 figures with moving comma in multiples of 10 &

100): indicates two types of TOTAL:

• Non-Resettable TOTAL (TOTAL)

• Resettable TOTAL (Reset TOTAL)

5. Indication of TOTAL multiplication factor (x10 or x100 ).

6. Indication of type of TOTAL, (TOTAL / Reset TOTAL).

7. Indication of unit of measurement of TOTALIZER:

L=Litres

Gal=Gallons

MAJOR COMPONENTS

Resettable

Batch Total

(Batch TOTAL)

Reset

Key

Calibration

Key

Non Resettable

Totalizer (TOTAL)

1"

Female

Port

1"

Male Port

1

2

3

4 5

6

7

8

FLOW RATE

8. Indication of unit of measurement of Resettable Batch

TOTAL:

Qts=Quarts

Pts=Pints

L=Litres

Gal=Gallons

FUNCTIONS:

User Buttons: The meter features two buttons (RESET and

CAL) which individually perform two main functions and together

perform other secondary functions.

• RESET key: is used to reset the Batch TOTAL and Reset

TOTAL

• CAL key: is used to enter calibration mode

• Combination of RESET + CAL keys: is used to change the

unit of measurement and other secondary functions.

Turbine Assembly: It has two threaded ports: 1 male & 1 female. It

contains a turbine which turns when media passes through it at

sucient pressure. This action generates electrical pulses which

are processed by a microprocessor and the result is displayed on

the LCD.

WHAT IS STANDBY?

When the media is not flowing through the meter, the meter

shows only the word TOTAL on the display. This mode is called

STANDBY and majority of adjustments are carried out in this

mode.

MEASUREMENT UNITS CONFIGURATION

The user can select the main measurement unit, Quarts (Qts),

Pints (Pts), Litres (L), Gallons (Gal); according to the following

predefined combinations:

Note: Last dispensed quantity can be brought to zero by

pressing and holding the RESET button.

Non Resettable

TOTAL

Last dispensed

quantity 12,435

1345,6TOTAL

Standby

Mode

reF. nO unit OF MeasureMent

resettable batch tOtal

unit OF MeasureMent

batch tOtalizer

1Litres (L) Litres (L)

2Gallon (Gal) Gallon (Gal)

3Quarts (Qts) Gallon (Gal)

4Pints (Pts) Gallon (Gal)

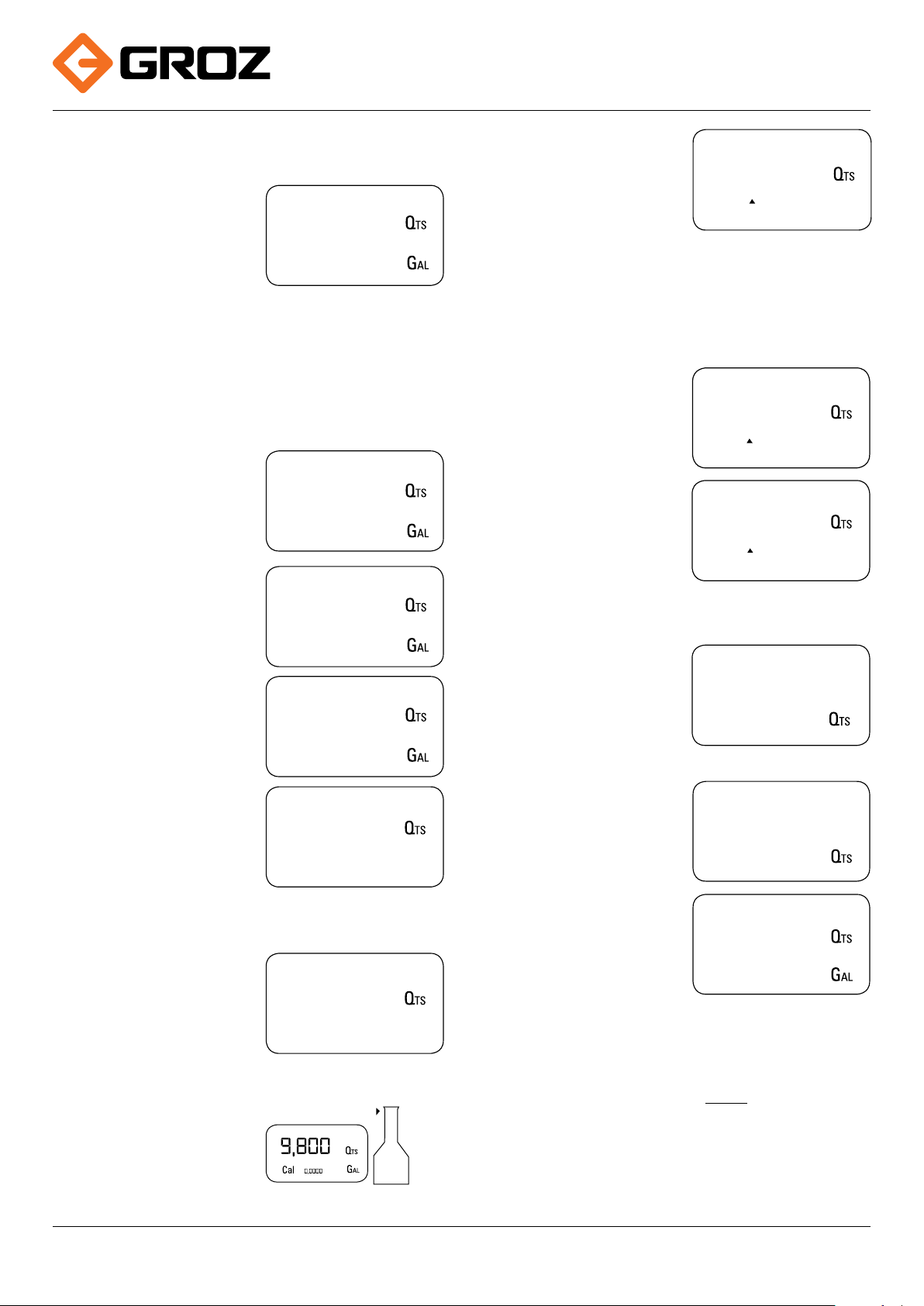

SEQUENCE OF SETTING THE UNIT OF MEASUREMENT

1. Wait for the METER to

go to Standby Mode.

2. Press the CAL and

RESET keys together.

Hold it until the word

“UNIT” appears on the

screen together with

the current unit of

measurement.

Unit QTS

GAL

12,345

123456

QTS

GAL

TOTAL

3. Press RESET key to scroll among the four combinations of

units of measurement as shown:

L

L

R RR

Positions