8

2.6 Description of dry-running protection

When the pump sucks air, the pump power input

decreases.

If the pump power input falls below the dry-running

power limit set in the R100 display 12.4.6 Dry-run-

ning stop, the pump will stop and the CU 300 will

indicate the dry-running alarm.

2.6.1 Function

The dry-running protection applies only if the motor

speed lies within the “maximum speed” range (i.e.

maximum speed less 1,000 min-1), see fig. 5.

Normally, “maximum speed” is 10,700 min-1. How-

ever, it can be reduced in the R100 display 12.4.8

Maximum speed. The dry-running power limit set in

display 12.4.6 Dry-running stop must match the

speed.

Changing the setpoint:

If the setpoint is changed by means of the R100 dis-

play 12.1.1 Setpoint or 12.4.2 External setpoint, the

pump can be forced to run at a reduced speed in

relation to the “maximum speed”. The dry-running

protection will not protect the pump if the reduced

speed lies outside the “maximum speed” range (i.e.

maximum speed less 1,000 min-1), see fig. 5.

Constant pressure control:

In constant pressure control mode, the dry-running

protection is active, as the motor will operate at

“maximum speed” in connection with dry running.

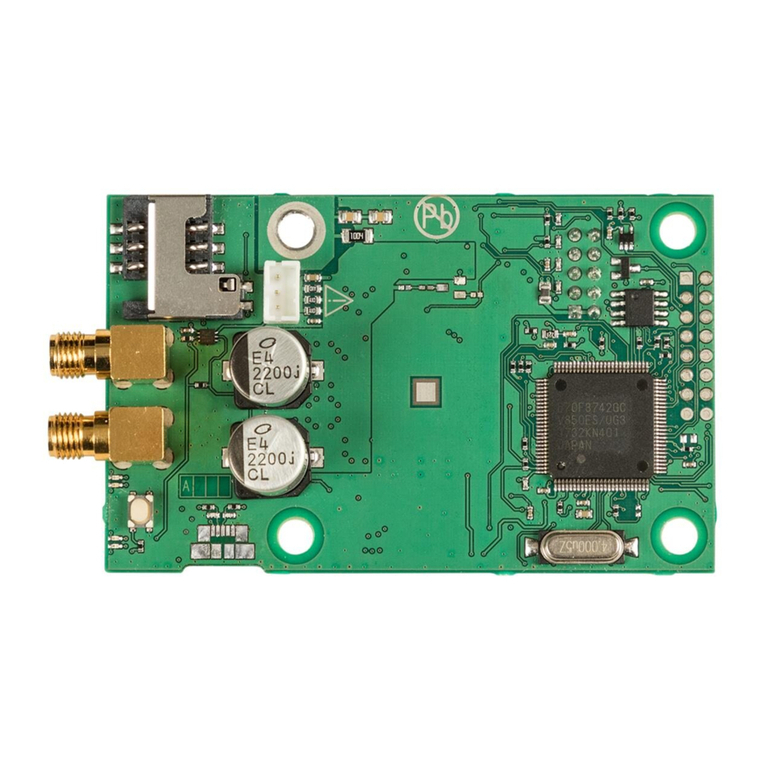

Pump power input curve:

The curve shows the pump power input in relation to

the pump speed.

Fig. 5

2.7 Settings

In the following section, the relevant R100 displays

and settings are shown and described.

For a detailed description of the R100 displays, see

section 12. CU 300 with R100. Each individual dis-

play has a number which refers to the section in

which it is described in detail.

2.7.1 Required R100 settings

If the maximum speed of the pump has been re-

duced by more than 1,000 min-1, the dry-running

stop value must be changed. In order to change the

dry-running protection function, the following R100

settings must be made:

Setting of dry-running power limit (dry-running

stop):

1. Start the pump against a closed discharge pipe.

2. Read the input power (P1) in the R100 display

12.2.5 Power input and power consumption.

3. Calculate the dry-running power limit,

P1x 0.9 [W].

4. Set this value in the R100 display 12.4.6 Dry-run-

ning stop.

2.8 Description of the dewatering function

When the pump sucks air, the pump power input

decreases.

If the pump power input falls below the dry-running

power limit set in the R100 display 12.4.6 Dry-run-

ning stop, the pump will stop.

During dewatering, the green indicator light in the

On/Off button on the CU 300 is flashing to indicate

that the pump has stopped.

2.8.1 Applications

The dewatering function can be used in applications

where the pump often runs dry, e.g.:

• in boreholes with a low yield.

• in boreholes and building sites where the water

table should be lowered.

TM01 2689 2598

as set in display

12.4.8

Max. speed

-1,000 min-1

Motor speed

Pump

power input

Pump power curve

Dry-running

power limit set

3,000 min-1

Watt

10,700 min-1

Display R100 setting

12.4.7 Dry-running

protection

Set “Dry-running protection”

to “Active”.

Note: In certain installations,

it may be necessary to dis-

able the dry-running protec-

tion. This is done in this

display. The disabling ap-

plies to the dry-running power

limit set in display 12.4.6 Dry-

running stop.

See fig. 5.

12.4.6 Dry-running

stop Set the dry-running power

limit, i.e. dry-running stop.

See “Setting of dry-running

power limit (dry-running

stop)” below and section 13.

Technical data.