English (GB)

2

English (GB) Functional profile and user manual

Original functional profile and user manual.

CONTENTS

Page

1. Symbols used in this document

2. Introduction

2.1 About this functional profile

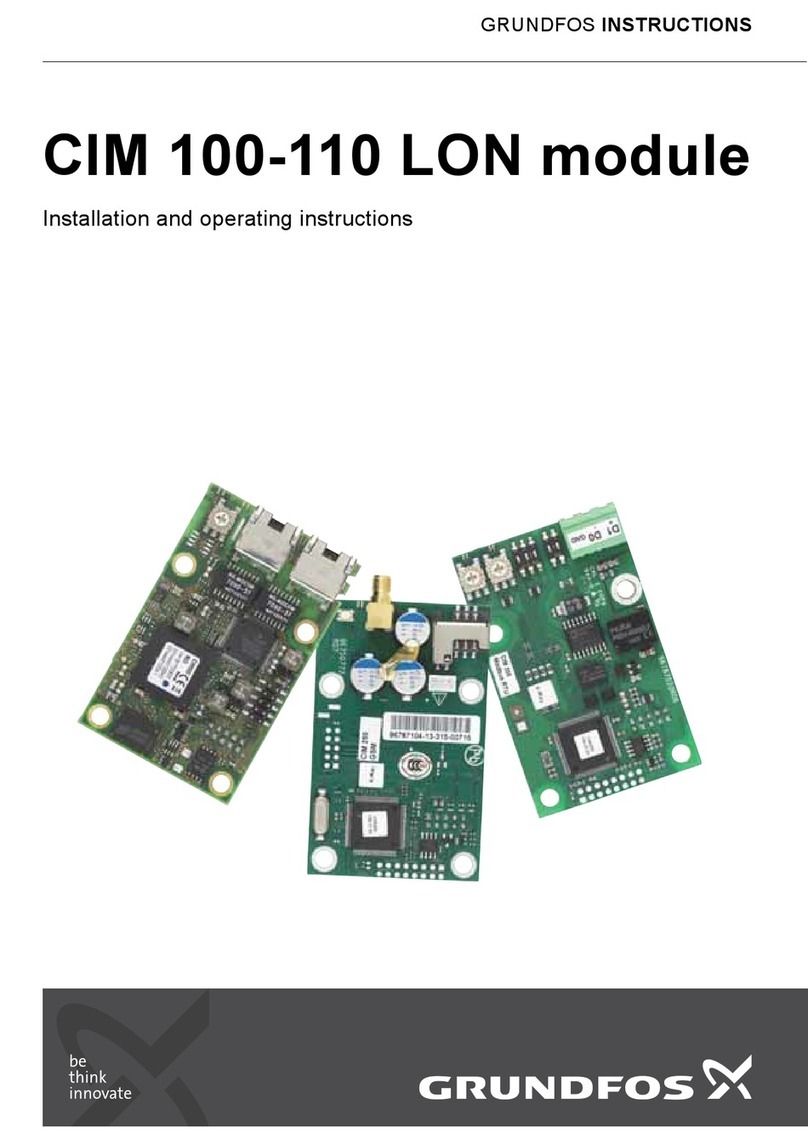

This functional profile describes the CIM 110 and CIU 110 for

LON communication with the following Grundfos booster

systems:

• Grundfos Hydro Multi-B (CU 323)

Hydro Multi-B is a complete booster system incorporating

Grundfos CM/CME pumps.

• Grundfos Hydro MPC (CU 352)

Hydro MPC is a complete booster system incorporating

Grundfos CRE pumps.

• Grundfos Control MPC (CU 352)

Control MPC can be built with different pump types to form a

booster system.

• Grundfos Multi-E

A booster set based on Grundfos MGE pumps model H and

later.

• Grundfos TPED twin-head pump with MGE motor, model H/I,

in multipump-mode (CIM 110 must be in the master pump

head).

• MAGNA3 Twinpump in multipump mode

Requires a CIM110 module installed in the master pump.

The CIU 110 incorporates a CIM 110 (LON Communication

Interface Module 110).

References in the following:

• The CIM 110 module is referred to as "LON module".

• The Hydro Multi-B, Hydro MPC, Multi-E and Control MPC are

referred to as "controller".

Control MPC and Hydro MPC are referred to as "Hydro MPC".

The data in this document are subject to change without prior

notice. Grundfos cannot be held responsible for any problems

caused directly or indirectly by using information in this functional

profile.

2.2 Assumptions

This functional profile assumes that the reader is familiar with

commissioning and programming LON devices. The reader

should also have some basic knowledge of the anatomy of LON

data communication.

1. Symbols used in this document 2

2. Introduction 2

2.1 About this functional profile 2

2.2 Assumptions 2

2.3 Definitions and abbreviations 3

2.4 System diagram 3

3. Installation 3

4. CIM 110 LON module 4

4.1 Connecting the LON module 4

4.2 Registration in a LON network 5

4.3 LEDs 5

5. Considerations when installing the controller 5

6. Selection of primary sensor 6

7. Power-on behaviour 6

8. SNVT/UNVT details 7

8.1 Mandatory and optional network variables 7

8.2 Manufacturer-defined network variables 7

8.3 Optional subpump (UFPT) network variables 7

9. SCPT/UCPT details 8

9.1 Configuration properties 8

10. Application examples 9

11. Override functionality 10

12. Details of the pump controller's functional blocks 11

12.1 Pump setpoint 13

12.2 Requested pump operating mode 13

12.3 Pump capacity 13

12.4 Effective operating mode 14

12.5 Effective device control mode 15

12.6 Pump status, diagnostic information 16

12.7 Pump differential pressure (standard range) 16

12.8 Pump differential pressure (extended range) 16

12.9 Pump inlet pressure 16

12.10 Pump discharge pressure (standard range) 16

12.11 Pump discharge pressure (extended range) 17

12.12 Pump external pressure (standard range) 17

12.13 Pump external pressure (extended range) 17

12.14 Pump flow (standard range) 17

12.15 Pump flow (extended range) 17

12.16 Flow-pipe liquid temperature 17

12.17 Return-pipe liquid temperature 17

12.18 Differential liquid temperature 18

12.19 Surrounding temperature 18

12.20 Tank level 18

12.21 Runtime 18

12.22 System status 18

12.23 Pump fault status 18

12.24 Alarm code 21

12.25 Warning code 21

12.26 Power consumption in kilowatts 21

12.27 Energy consumption 21

12.28 Send heartbeat 21

12.29 Control mode for normal operation 21

13. Details of the subpump's functional block 22

13.1 Pump speed 22

13.2 Pump runtime 22

13.3 Pump fault status 22

13.4 Pump status, diagnostic information 24

14. Details of the node object's functional block 25

14.1 Object request 25

14.2 Object status 25

14.3 Location label 25

15. Manufacturer-specific variables 26

15.1 Grundfos info 26

15.2 Device resource files 26

16. Sensor ranges 27

16.1 Positive sensor ranges 27

16.2 Negative sensor ranges 27

17. Fault finding 28

If these safety instructions are not observed, it may

result in malfunction or damage to the equipment.

Notes or instructions that make the job easier and

ensure safe operation.