English (GB)

7

4.2.1 Letter codes for shaft seals

For a thorough description of shaft seal types and

materials, see the English-language data booklet

entitled "NB, NBG, NK, NKG, NBE, NBGE, NKE,

NKGE - Custom-built pumps according to EN 733

and ISO 2858".

5. Applications

5.1 Pumped liquids

Clean, thin, non-explosive liquids without solid

particles or fibres. The pumped liquid must not attack

the pump materials chemically.

6. Operating conditions

6.1 Ambient temperature and altitude

The ambient temperature and the installation altitude

are important factors for the motor life as they affect

the life of the bearings and the insulation system.

If the ambient temperature exceeds the

recommended maximum ambient temperature or the

installation altitude exceeds the recommended

maximum altitude above sea level (see fig. 6),

the motor must not be fully loaded due to the low

density and consequently low cooling effect of the

air. In such cases, it may be necessary to use a

motor with a higher output.

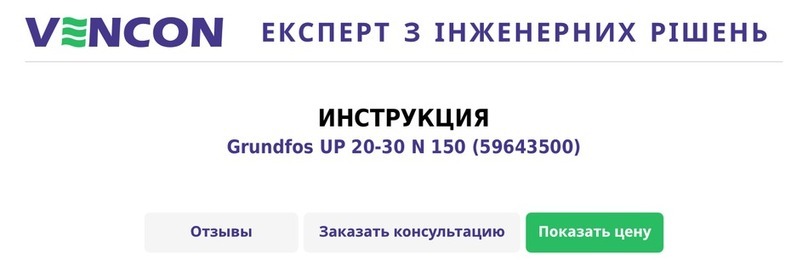

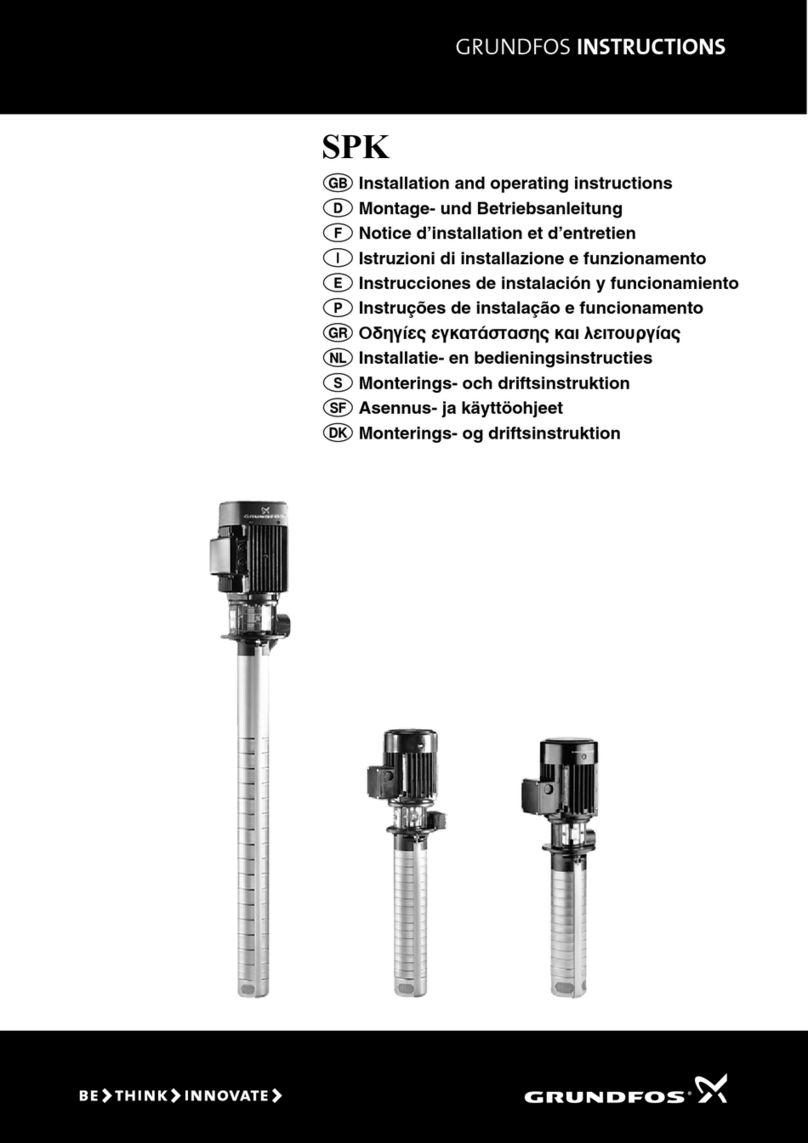

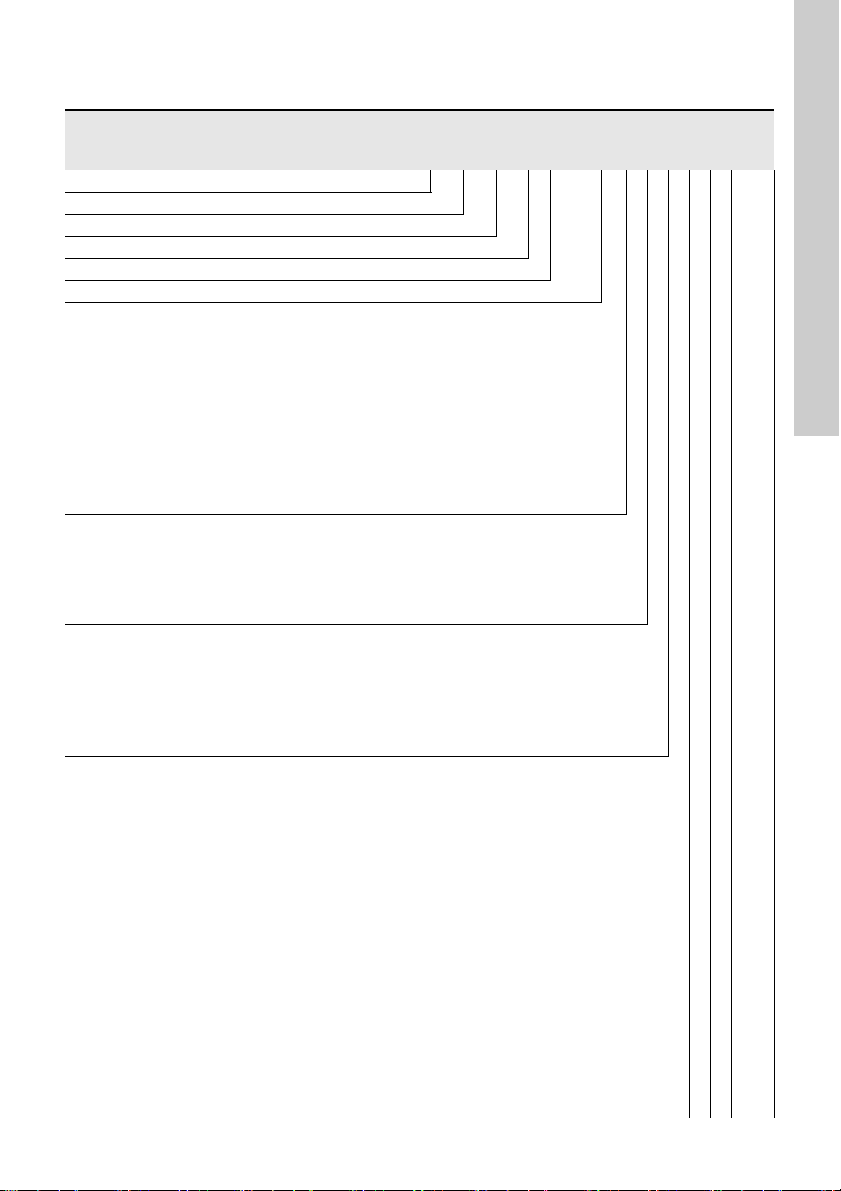

Fig. 6 The maximum motor output depends on

the ambient temperature and altitude

Legend

Example: A pump with a 1.1 kW IE2 MG motor: If

this pump is installed 4750 m above sea level, the

motor must not be loaded more than 88 % of the

rated output. At an ambient temperature of 75 °C,

the motor must not be loaded more than 78 % of the

rated output. If the pump is installed 4750 m above

sea level at an ambient temperature of 75 °C, the

motor must not be loaded more than 88 % x 78 % =

68.6 % of the rated output.

6.2 Liquid temperature

-40 °C to +140 °C.

The maximum liquid temperature is stated on the

pump nameplate. It depends on the shaft seal

chosen.

For EN-GJL-250 cast iron pump housings, local

regulations may not allow liquid temperatures above

+120 °C.

Example: 10 = BAQE B A Q E

Shaft seal type

A O-ring seal with fixed driver

B Rubber bellows seal

D O-ring seal, balanced

GBellows seal, type B, with reduced

seal faces

H Cartridge seal, balanced

Material, rotating seal face

A

Carbon, metal-impregnated

(antimony (not approved for potable

water))

B Carbon, resin-impregnated

Q Silicon carbide

Material, stationary seat

A

Carbon, metal-impregnated

(antimony (not approved for potable

water))

B Carbon, resin-impregnated

Q Silicon carbide

Material, secondary seal and other rubber

and composite parts, except the wear ring

EEPDM

VFKM(Viton

®)

F FXM (Fluoraz®)

K FFKM (Kalrez®)

XHNBR

UDynamic O-rings in FFKM and static O-rings

in PTFE

TM04 4914 2209

Pos. Description

1 0.25 - 0.55 kW MG motors

20.75 - 22 kW MG motors (IE2/IE3)

0.75 - 450 kW MMG-H motors (IE2)

3 0.75 - 462 kW Siemens motors (IE2)

20 25 30 35 40 45 50 55 60 65 70 75 80

50

60

70

80

90

100

[%]

P2

1

2

3

t[°C]

1000 2250 3500 4750 m