NOTE: UPS15-42 does not require manual turning of shaft.

Pump Mounting: For Indoor Use

Arrows on the side or bottom of the pump housing indicate

direction of flow through the pump. GRUNDFOS

circulators can be installed in both vertical and horizontal

lines. The pump must be installed with the motor shaft

positioned horizontally.

Under no circumstances should

the pump be installed with the shaft vertical or where the

shaft falls below the horizontal plane. See Figure 3B.

It is recommend that isolation valves be installed on each

side of the pump. If possible, do not install elbows, branch

tees, and similar fittings just before or after the pump.

Provide support to the pump or adjacent plumbing to

reduce thermal and mechanical stress on the pump.

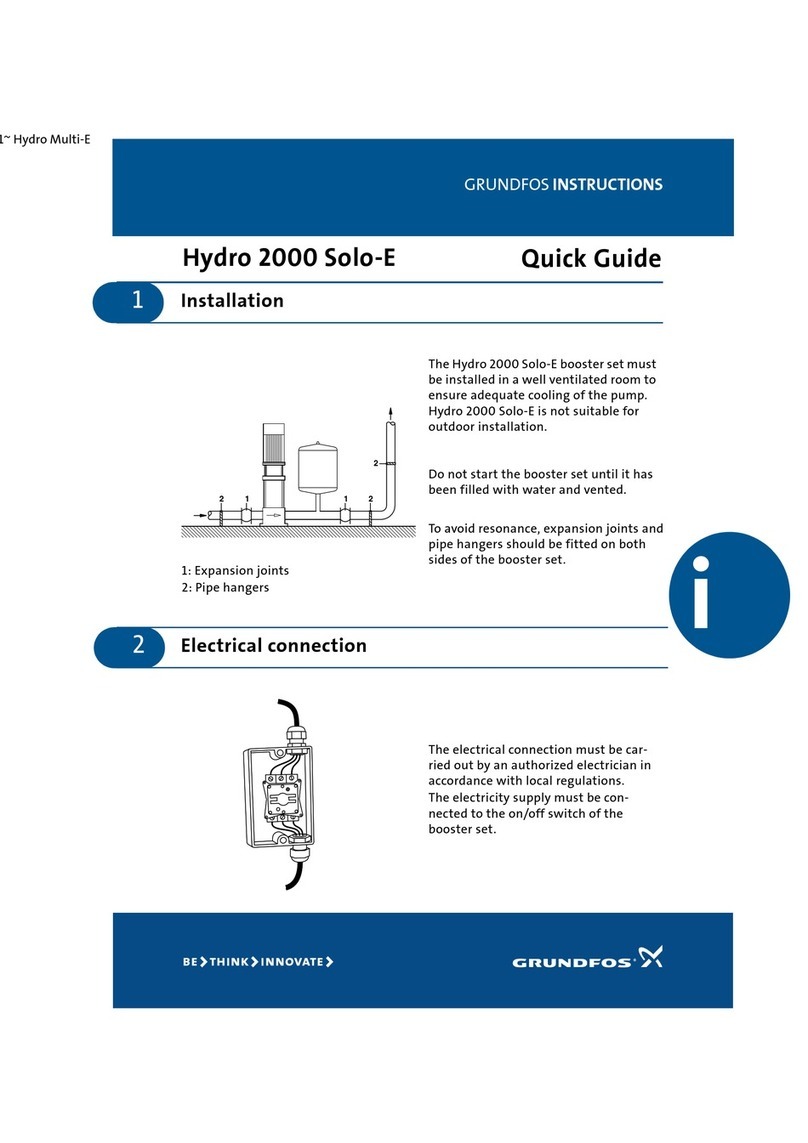

Installation Requirements

1. Thoroughly clean and flush the system prior to pump

installation.

2. Do not install the pump at the lowest point of the system

where dirt and sediment naturally collect.

3. Install an air vent at the high point(s) of the system to

remove accumulated air.

4. Ensure that water does not enter the terminal box

during the installation process.

5. (Open System) Install the pump in the supply line; the

suction side of the pump should be flooded with water.

Ensure that the static head requirement from Table 2B

is achieved.

6. (Closed System) Install a safety relief valve to protect

against temperature and pressure build-up.

7. If there are excessive suspended particles in the water,

it is recommended that a strainer and/or filter be

installed and cleaned regularly.

8. DO NOT START THE PUMP UNTIL THE SYSTEM

HAS BEEN FILLED AND CHECKED FOR LEAKS OR

OTHER POSSIBLE COMPONENT FAILURES.

Position of terminal box:

Proper installation of the pump will have the terminal box

located to one side of the pump or the other, with the

conduit entry down. See Figure 3A.

If the terminal box position needs to be changed, it is best

to do so before installation. However, if the pump is already

installed, ensure that the line cord is unplugged and close

the isolation valves before removing the Allen screws.

To change terminal box position:

1. Remove the four (4) Allen screws from the pump

housing and stator (4 or 5mm wrench) while supporting

the stator (motor).

2. Carefully separate the stator from the pump housing

and rotate it to the correct terminal box orientation and

reseat it.

3. Replace the Allen screws and tighten diagonally and

evenly (7 ft.-lb. torque).

4. Check that the motor shaft turns freely. Remove the

large screw in the middle of the nameplate, insert a

small flat blade screwdriver into the end of the shaft,

and turn gently (see fig. 7a).

If the shaft does not turn easily, repeat the disassembly/

reassembly process.

Examine the components carefully to make sure no

damage has occurred to the pump during shipment. Care

should be taken to ensure the pump is NOT dropped or

mishandled; dropping will damage the pump.

1. Shipment Inspection

2. Pre-Installation Checklist

Before beginning installation procedures, the

following checks should be made. They are all

important for proper installation of the circulator

pump.

1. Uses:

Model UP 15 series pumps are designed to circulate

water from 50°F to 230°F up to a maximum pressure of

145 psi. If required, a 50% by volume solution of ethylene

or propylene glycol and water can be used, however, a

psi decrease in pump performance may result due to an

increase in the viscosity of the solution. Check with

manufacturer for information regarding suitability of

pumping other fluids.

System Applications: UP15 series pumps with

stainless steel or bronze volutes can be used in both

open and closed systems.

2. MaximumWaterTemperature:

UP15 pump with line cord only. The maximum allowable

water temperature is determined by the ambient or

surrounding air temperature as shown in Table 2A.

Table 2A – Maximum Water Temperature

Ambient (°F) 95 130 140 160 175

Water (°F) 230 220 210 190 175

Although the pump is designed to operate at maximum

water temperature of 230°F, it is recommended to

keep the operating temperature as low as possible (i.e.

below 140°F to avoid precipitation of calcium).

3. Inlet Pressure Requirements

The amount of pressure required at the inlet of the pump

is a function of the temperature of the water as shown in

Table 2B.

Table 2B – Inlet Pressure Requirements

Water (°F) 190 165 140

Required Inlet Pressure (ft.) 5 4.5 3

(psi) 2.2 1.9 1.3

In a pressurized system, the required inlet pressure is the

minimum allowable system pressure.

In an open system, the required inlet pressure is the

minimum distance the pump must be located below the

lowest possible water level of the water source (tank,

pool, etc.).

3. Pump Installation

Figure 3A

Recommended Terminal Box Orientation

4. Electrical

SAFE WARNING

Warning - Risk of electrical shock - This pump is supplied

with a grounding conductor. To reduce the risk of electric

shock, be certain that it is connected only to a properly

grounded grounding type receptacle.

The safe operation of this pump requires that it be grounded

in accordance with the National Electrical Code and local

governing codes and regulations.

Electrical Requirements

The operating voltage and other electrical data are marked

on the motor label. Make sure that the motor is suitable for

the electrical supply on which it will be used.

Electrical Connection

Insert the 115V plug on the line cord from the pump into a

properly grounded 115V outlet as shown in Figure 4a.

5. TimerTechnical Data

TIMER CONTROL

Supply Voltage: 115-120 VAC, 60 hertz

Contact Rating: 16 amps

Ambient Temperature: -4°F to 175°F

Shortest Switching Interval: 15 minute increment

Switch Modes: “Timer”, “ON” Override,

“OFF” Override

Protection: Clear plastic cover for dust and

moisture protection of the clock face.

Note: UP15 pump with timer control maximum water tem-

perature: 150°F

6. TimerTechnical Application

The Grundfos timer control is designed only for use with

specified Grundfos Series UP circulators installed in in-

door hot water service systems.

The timer control is designed to turn the circulator on and

off at preset times, allowing the user to select operation of

the circulator during high use periods of the day.

Figure 3B

Acceptable Unacceptable

Page 1 Page 2 Page 3 Page 4