Introduction

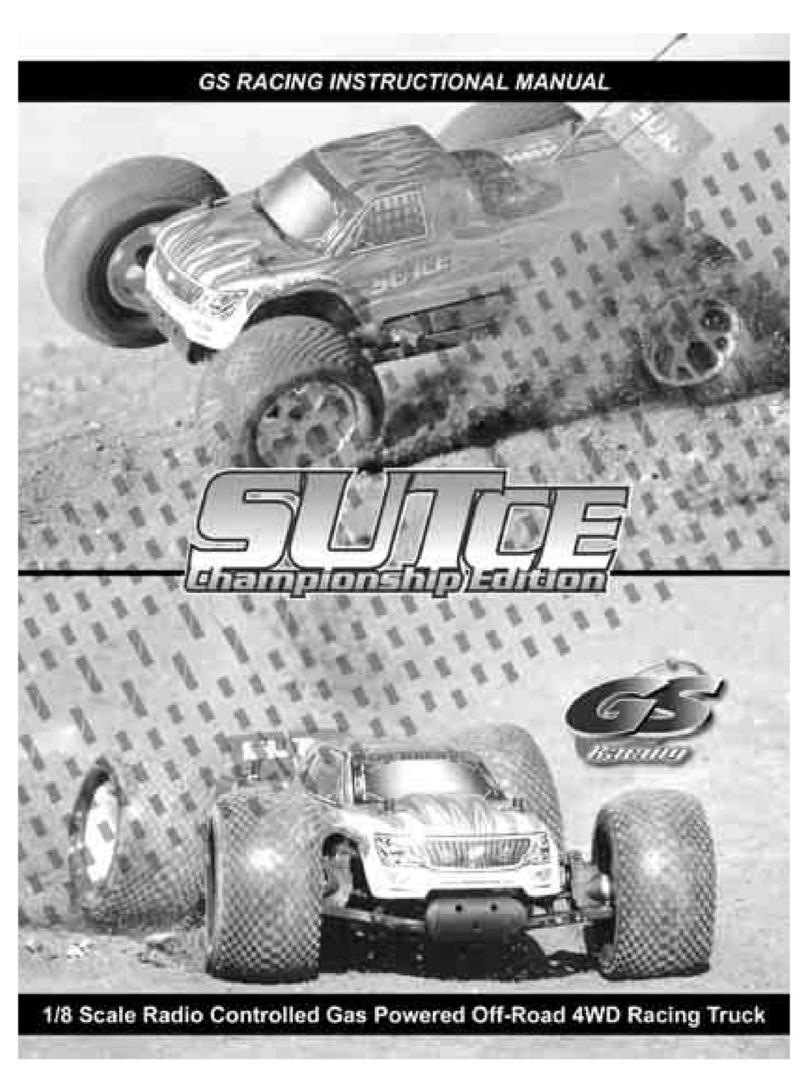

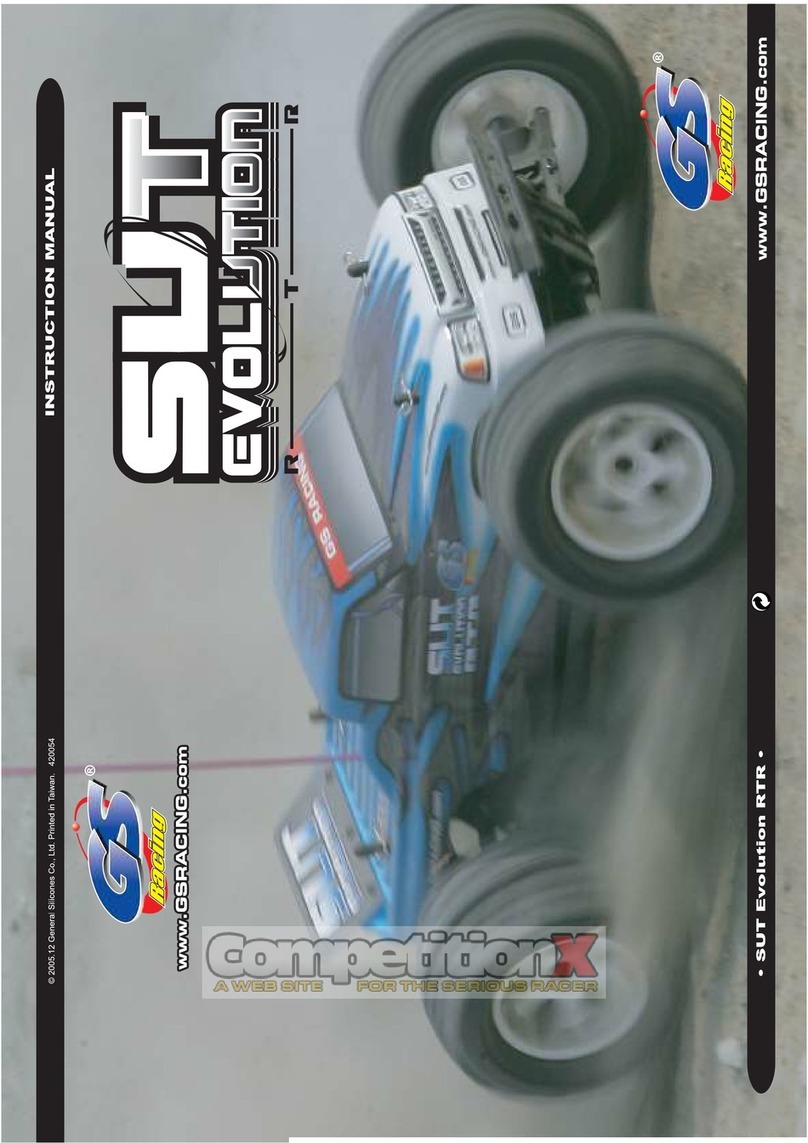

Congratulations and thank you for choosing the GS Racing Storm Unlimited Truck Championship Edition,

SUT-CE for short. The SUT-CE is a limited edition, modied, factory spec replica of the truck we have used

to win numerous titles including back to back National Championships. Only 1000 will be produced, so if you

are reading this, you belong to an elite club of RC racers. New for the SUT-CE are the redesigned and longer

chassis, heavy duty suspension mounts, ultra thick steering plate, and Korn Designs pre-painted body. The truck

comes assembled with our team setup installed, so all you have to do is install radio gear, glue tires, and hit the

track. The SUT-CE is a highly developed racing vehicle and is not designed to be an entry level model. Some

mechanical experience and/or parental supervision are required. This manual contains all the basic instructions

to nish assembly of, and break in, operation, and maintenance of your SUT-CE. It is critical that you read all

the instructions in this, and any/all accompanying guides, in order to operate your model correctly and avoid

serious damage. Your hobby dealer cannot, under any circumstances, accept a model for return or exchange

that has been run. We have taken the time to build your truck with our best setup, take the time to follow our

instructions to ensure winning results with your SUT-CE. If you should ever have any questions or need help

with this or any GS product, please feel free to contact our ofcial GS Racing dealers and distributors, as they

will be happy to help you. Good luck and good racing!

Safety Precautions

This is a high performance radio controlled model which needs to be operated with caution and common

sense. Failure to operate your model in a safe and responsible manner could result in personal injury and/or

property damage. It is your responsibility to read and follow all safety precautions. The SUT-CE is not intended

for children under the age of 14 without adult supervision. GS Racing shall not be held liable for any loss or

damages, whether direct, indirect, act of nature, arising from the abuse or misuse of this product or any other

product required while operating this model.

-Fuel can be dangerous is improperly handled. Follow all of the manufacturer’s suggestions.

-Always keep fuel in a cool area and never use near ame, sparks, or while smoking.

- Keep fuel and other ammables out of the reach of children.

-Always run your model in a well ventilated area outdoors. Never run your model indoors.

-All parts of the engine and exhaust can become extremely hot during, and after use. Be careful not to touch

these parts especially when refueling, or making repairs.

- This model creates high levels of noise. Use ear protection is you nd noise objectionable.

-This model is controlled by a radio frequency that is vulnerable to interference from many outside sources.

This interference can cause a loss of control so it is necessary to operate this model in an open area to avoid

personal, or property damage. Always ensure no one is using your frequency before turning on your radio or

model.

- Read, understand, and follow the instruction included with your radio gear.

- Never operate your model near people or property. The speed of this model has the potential for injury and

or damage to people and or property.

Never use anything other than model car fuel.

Never operate the model with a low battery. If the response becomes slow, stop immediately and replace

batteries.

Never run the model without a clean and properly installed air cleaner.

Never run the model lean or allow the engine to overheat.

OPERATION GUIDE

2