i

Table of Contents

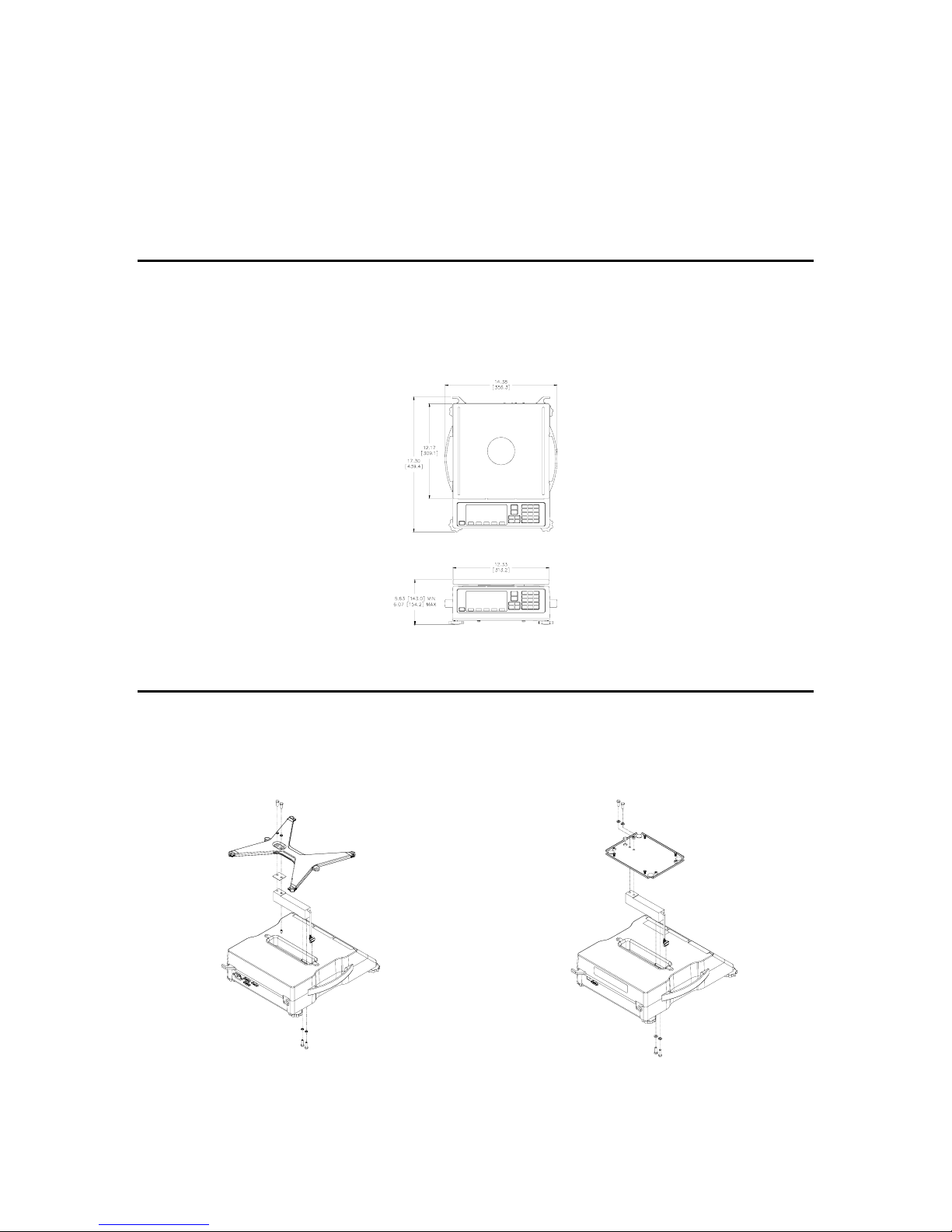

CHAPTER 1: INTRODUCTION ............................................................................................................... 1

E

NCLOSURE

................................................................................................................................................. 1

L

OAD

C

ELL

R

EPLACEMENT

......................................................................................................................... 1

Load Cell Connections ........................................................................................................................... 2

K

EYPAD

...................................................................................................................................................... 2

Model 370............................................................................................................................................... 2

MODEL 375........................................................................................................................................... 3

D

ISPLAY

...................................................................................................................................................... 5

Annunciators .......................................................................................................................................... 5

R

EAR

P

ANEL

C

ONNECTIONS

........................................................................................................................ 5

Communication Port 1............................................................................................................................ 6

Remote Display Connections.................................................................................................................. 6

CHAPTER 2: OPTION INSTALLATION................................................................................................ 7

C

OMMUNICATION

........................................................................................................................................ 7

RS-485 Networking................................................................................................................................. 7

20 mA Current Loop Option................................................................................................................... 9

A

NALOG

O

UTPUT

O

PTION

......................................................................................................................... 11

S

ETPOINT

O

PTION

..................................................................................................................................... 12

Setpoint Card Connections................................................................................................................... 13

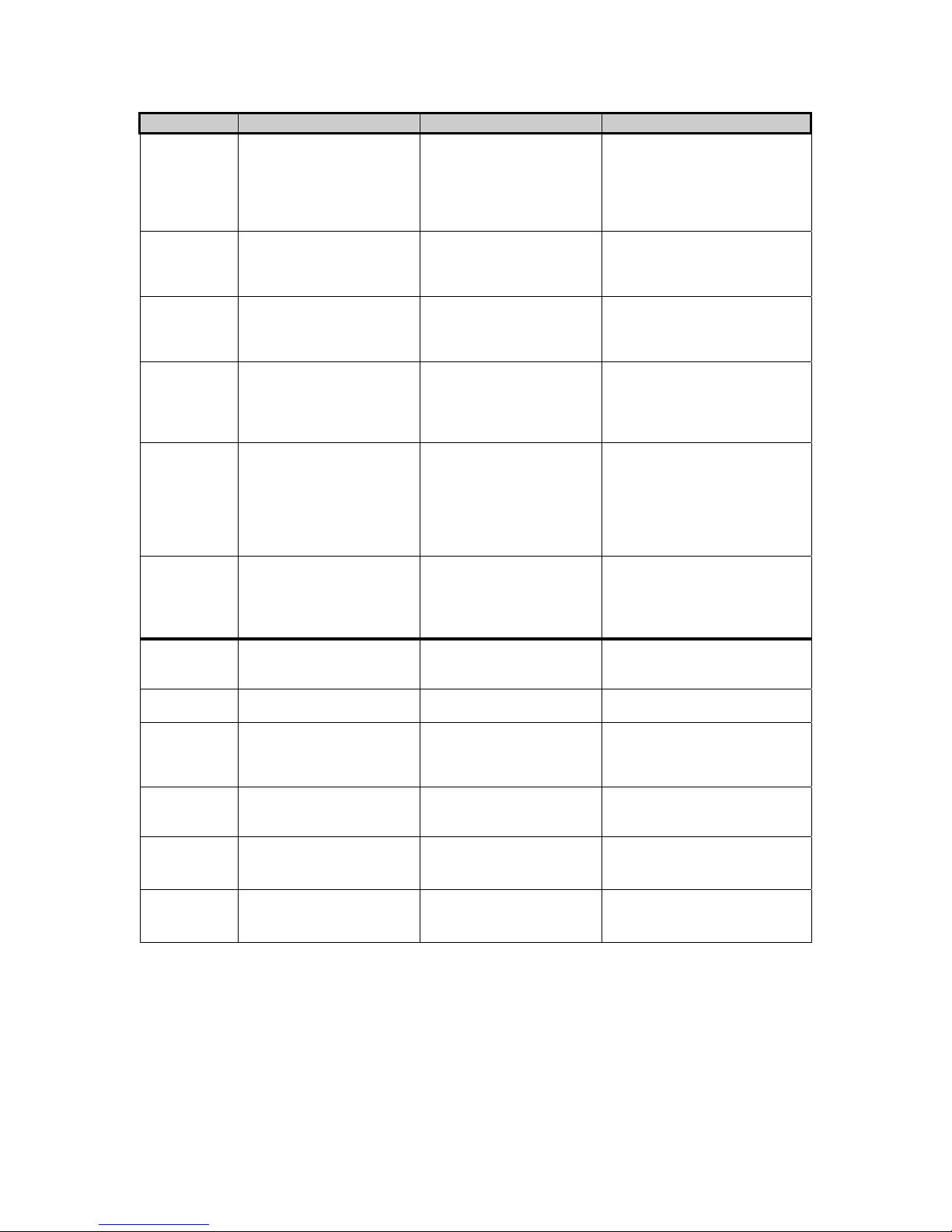

O

PTION

M

OUNTING

B

RACKET

................................................................................................................... 13

CHAPTER 3: SCALE CONFIGURATION ............................................................................................ 15

E

NTERING THE

S

ETUP

M

ODE

(M

ODEL

370)............................................................................................... 15

E

NTERING THE

S

ETUP

M

ODE

(M

ODEL

375)............................................................................................... 16

S

ELECTING A

P

ARAMETER

......................................................................................................................... 16

C

HANGING A

P

ARAMETER

V

ALUE

............................................................................................................. 17

Selection Parameters............................................................................................................................ 17

S

AVING

P

ARAMETERS

............................................................................................................................... 19

F

ACTORY

D

EFAULT

................................................................................................................................... 20

L

IST OF

P

ARAMETERS

................................................................................................................................20

Parameter Map Details........................................................................................................................ 23

P

RINTING

................................................................................................................................................... 29

Preset Transmit Selections ................................................................................................................... 29

Custom Transmit .................................................................................................................................. 31

A

NALOG

O

UTPUT

P

ARAMETER

S

ETUP

....................................................................................................... 35

Analog Output Example........................................................................................................................ 35

S

ETPOINT

C

ONFIGURATION

....................................................................................................................... 36

Activation Methods (General).............................................................................................................. 37

Percentage Check-Weighing ................................................................................................................ 39

Fill........................................................................................................................................................ 40

Batch..................................................................................................................................................... 41

Discharge ............................................................................................................................................. 43

Both ...................................................................................................................................................... 45

Absolute Check-Weighing..................................................................................................................... 46

Independent Setpoint Operation........................................................................................................... 47

Target Deviation Check-Weighing....................................................................................................... 49

P

ARTS

C

OUNTING

...................................................................................................................................... 50

R

EMOTE

S

ERIAL

O

PERATION

..................................................................................................................... 51

DISPLAY CAPTURE UTILITY............................................................................................................. 51

T

IME AND

D

ATE

S

ETUP

(M

ODEL

370)....................................................................................................... 52