10 PNEG-523 Dryer Start-Up

4. Start-Up Procedure

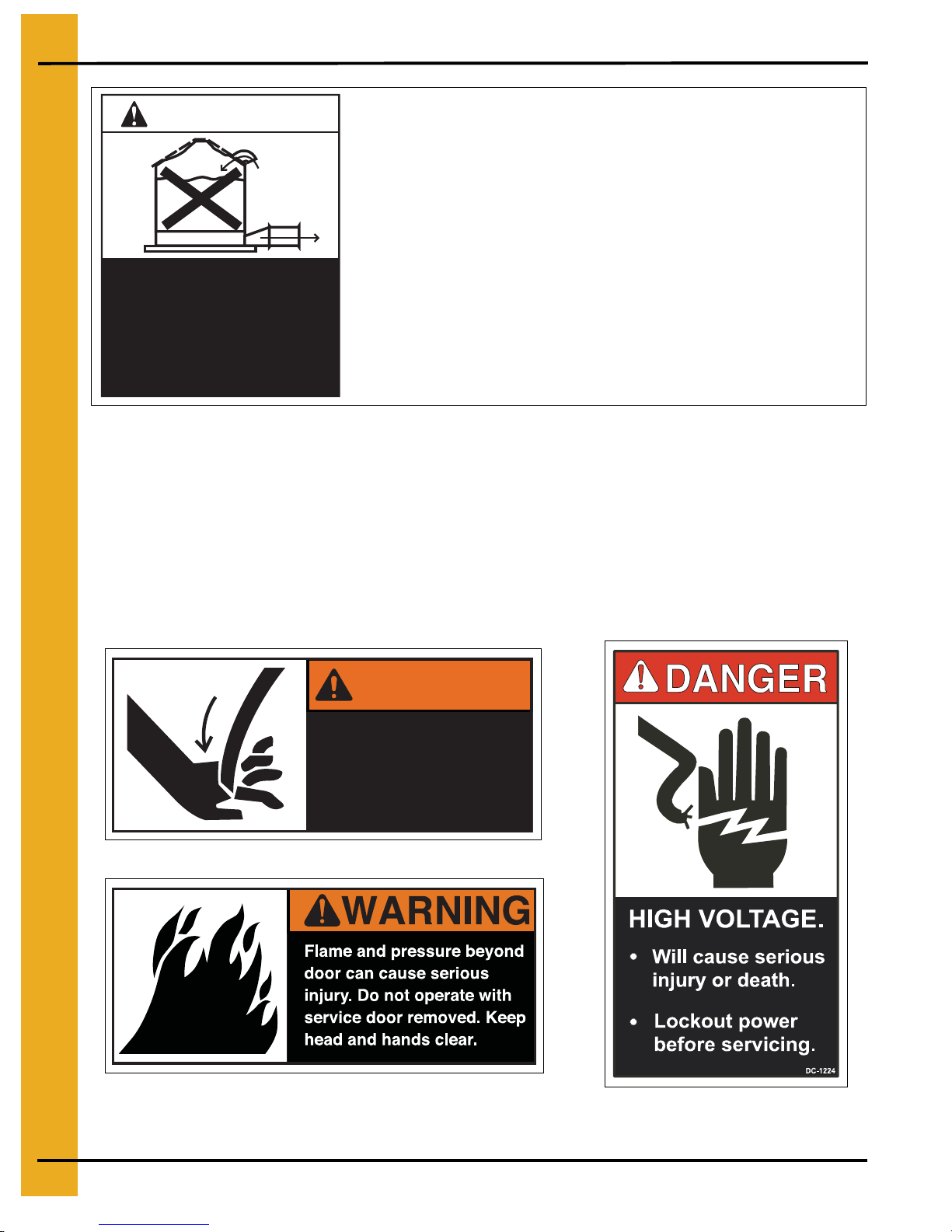

Standard electrical safety practices and codes should be followed when working with a dryer. Refer to

the National Electric Code Standard Handbook by the National Fire Protection Association. A qualified

electrician must make all wiring installations.

Full Start-Up Check

This start-up procedure assumes the following:

1. You have read and understand the DRYER OPERATION AND SERVICE MANUAL.

2. You have taken special note of all SAFETY PRECAUTIONS.

3. All safety shields are in place.

4. All meter roll access doors have been opened and all foreign objects have been removed.

5. You have done a pre-start-up check.

6. All motors have been checked for proper rotation.

7. All heaters have been test fired.

8. The fuel has been turned ON at the tank.

9. The electric power has been turned ON.

10. The main disconnect switch on the dryer is ON.

11. There is wet grain in the wet holding bin.

12. Incoming grain moisture is known.

13. Dry grain take away equipment is in place.

14. Grain is going to the proper bin.

15. Switches other than fuel, electric power and main disconnect have been set to the OFF position.

16. The load mercury switch box is installed with the side stamped “UP”, in the up position.

Filling the Dryer

1. Turn the green CONTROL POWER knob to ON. It will light up and scroll through four (4) screens

and finish by displaying the time and date.

2. Turn the DRYING MODE switch to CONTINUOUS FLOW.

3. Push the RESET button on the computer keypad to activate the computer.

4. Make sure the UNLOAD switch is in the OFF position.

5. Push the DRYER POWER start switch; it will light up.

6. Turn the LOAD AUGER switch to the MANUAL position to fill the dryer. The load auger will start

and run until the dryer is full and then shut off automatically. (If the switch is set to the AUTO

position the dryer will shut down each time the Out of Grain timer times out and will have to

be restarted).

7. When the dryer has filled, turn the LOAD AUGER switch to the AUTO position.

Always disconnect and lock out power before working on or around dryer.