4

Introduction

PNEG-1391 8",10", & 12" BE-SAW Augers

INTRODUCTION

GENERAL OVERVIEW

The Bucket Elevator Swing Away Auger (BE-SAW) is

pimarily used for unloading grain trucks/wagons. The

BE-SAW hopper is placed under the unload chute

and augers the grain to a new location.

The manufacturer reserves the right to improve its

product whenever possible and practical to do so.

We reserve the right to change, improve and modify

products at any time without obligation to make

changes, improvements and modifications on equip-

ment sold previously.

The BE-SAW Augers have been designed and

manufactured to give years of dependable service.

The care and maintenance of this equipment will

effect the satisfaction and service obtained. By

observing the instructions and suggestions we have

recommended, the owner should receive competent

service for many years. If additional information or

assistance should be required, please contact your

dealer or the manufacturer.

CAPACITY

A. The capacities of augers or screw

conveyers varies greatly under varying

conditions. The following factors play a role in

the performance of the auger:

• Speed

• Angle of operation

• Moisture content

• Amounts of foreign matter

• Methods of feeding

• Different materials

B. An auger operating at a 25° incline might

experience 20% less capacity than an auger

operating horizontally. Twenty-five percent

(25%) moisture could cut capacity by as much

as 40% under some conditions.

GENERAL INFORMATION

READ THIS MANUAL carefully to learn how to properly

use and install equipment. Failure to do so could result

in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The

Customer is responsible for ensuring that all quantities

are correct. Report any damage or shortages by

recording a detailed description on the Bill of Lading to

justify the Customer’s claim from the Transport Firm.

THIS MANUAL SHOULD BE CONSIDERED a

permanent part of your equipment and should be easily

accessible when needed.

WARRANTY is provided as part of the company’s

support program for customers who use and maintain

their equipment as described in the manual. The

warranty is explained on the warranty page located on

inside back cover.

This warranty provides you the assurance that the

company will back its products where defects appear

within the warranty period. Should the equipment be

abused, or modified to change its performance beyond

the factory specifications, the warranty will become void

and field improvements may be denied.

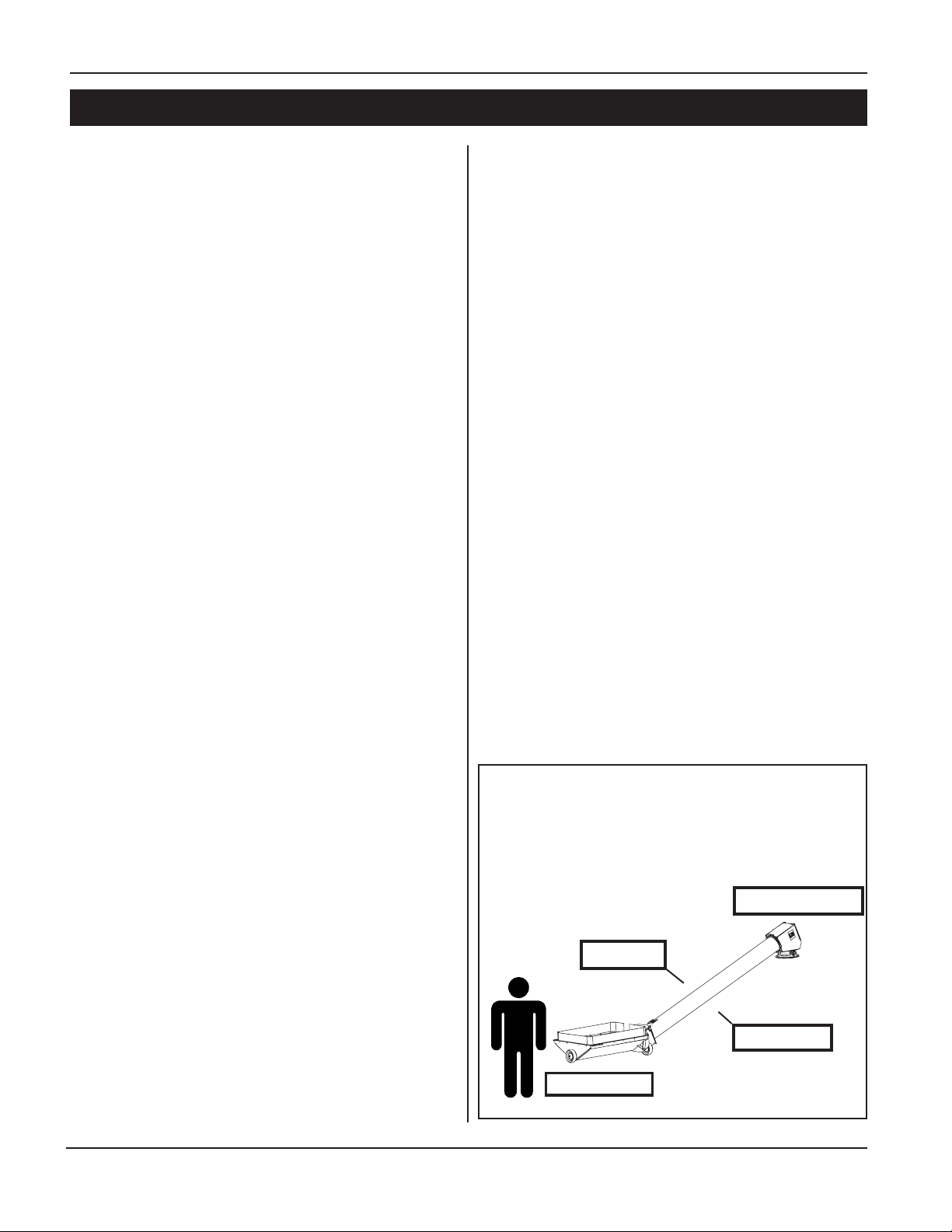

Left Side

Discharge End

Right Side

Intake End

For the purpose of this manual, if you stand at

the intake end of the auger looking towards

the discharge end, your left is the left side of

the auger; your right is the right side of the

auger.