GTE Industrieelektronik GmbH

Subject to technical changes FPM Vision – EN02 Page 2 of 15

Safety information

Read this documentation carefully and familiarize yourself with the product prior to its

use. Pay particular attention to the safety information and warnings to avoid injuries and product

damage. Keep this documentation readily available for later use as needed. Pass on this document to future

users of the product.

To avoid physical injury or significant damage to property, only qualified persons should be allowed to work with

the measuring equipment. Qualified persons are deemed to be those who are familiar with the setup, installation,

initial operation and running of collaborative robots and who have the requisite qualifications for this kind of

activity. They must be able to diagnose the tasks they are asked to conduct, recognise potential sources of risk

and take adequate safety measures.

Purpose

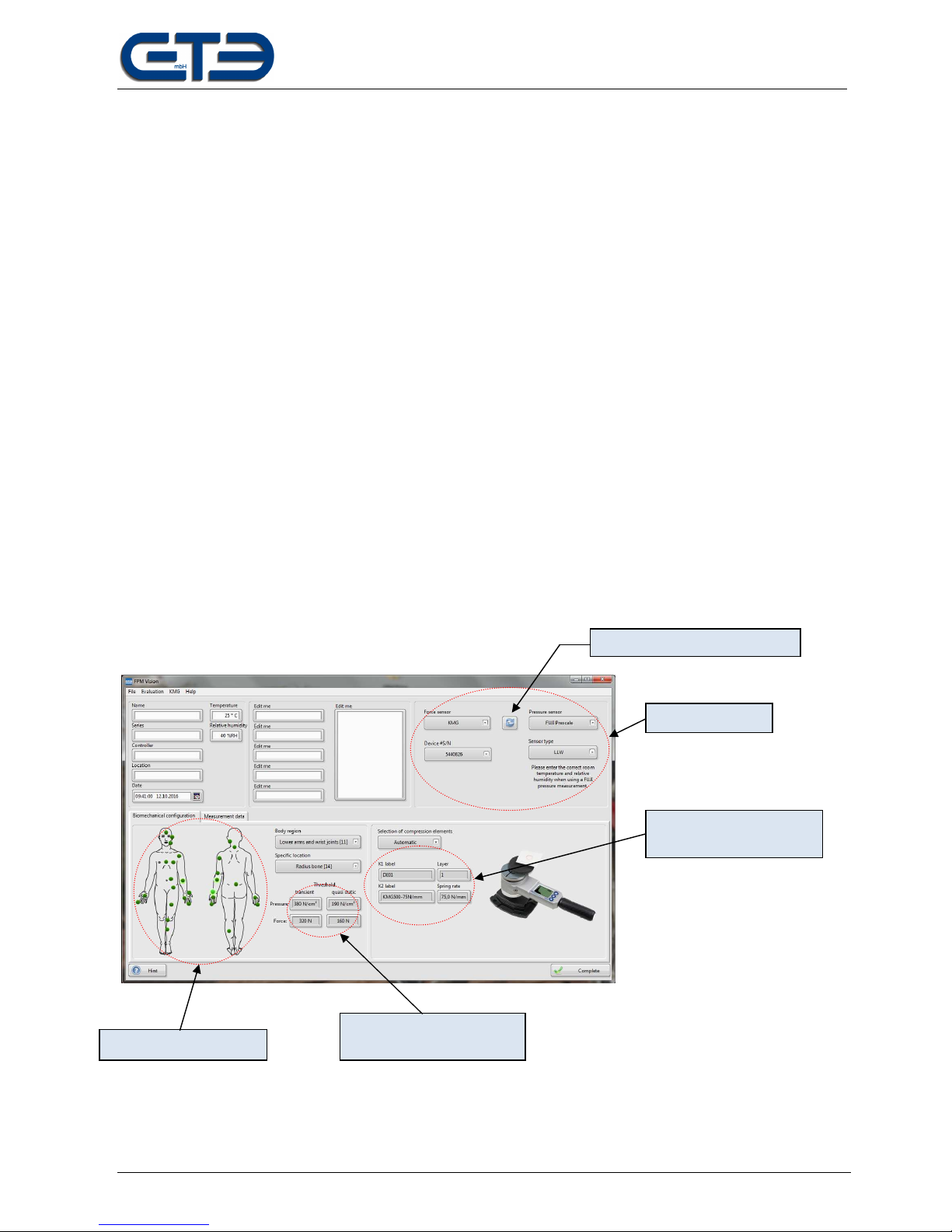

The software is designed for the visualization, analysis, editing, and archiving of force measurements

Recorded using the KMG 300-75 and KMG 500-75 measuring systems and of pressure images generated using

Fuji-Prescale films. The measurement method is used for determining impact and clamping forces at

collaborative robots based on ISO/TS 15066. It may only be used for this purpose.

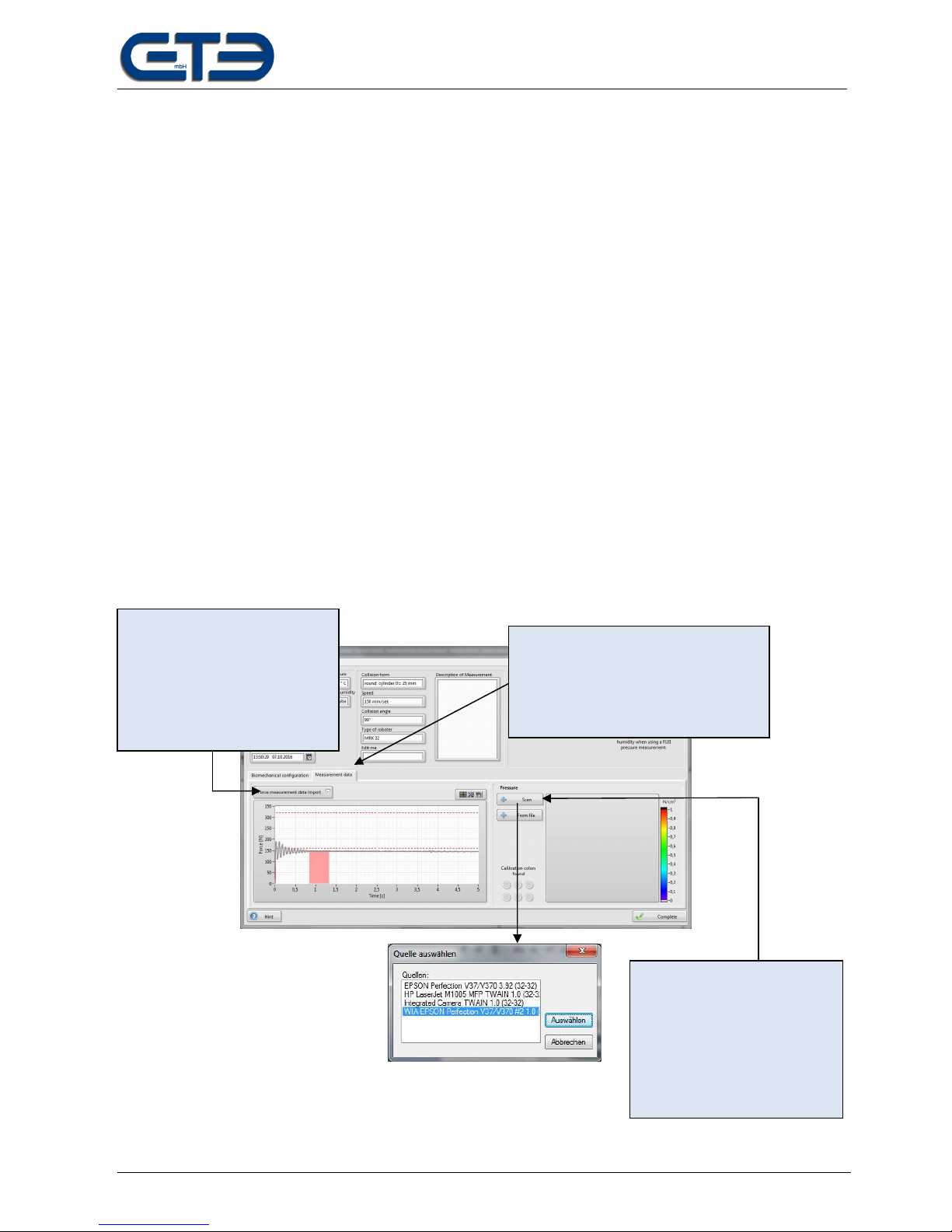

The software specifies the configuration of compression elements on basis of the selected body region. It offers

an import function for printed images with automatic filtering and color calibration. It features an integrated report

generation for data archiving purposes.

Scope of the system

•KMG 300 and/or KMG 500 force gauge

•Power supply: AC100-240V to DC5V

•Voltage converter DC12-24V to DC5V

•USB-A to USB-B Mini cable

•Transport case for force gauge

•Compression elements K1

•USB stick with PC software FPM Vision

•Mounting base with adapter

•EPSON scanner V370

•Scanner power supply

•USB-A to USB-B cable

•Calibration element for scanner

•Fuji-Prescale film, 2-piece

FPM VISION software updates

Due to possible normative changes further updates may be necessary. You can find the current version of the

software on our homepage www.gte.de/downloads. We recommend visiting our webpage regularly and after

normative changes and checking the software for available updates.