CONDITIONS OF OPERATION

Adjusting the LightRail 5.0 Commercial Drive variable time delay will be up to you, as all gardens are different. We suggest first setting the delay to 30 sec-

onds. Then after observing your plant growth you may want to change the length of delay. A longer delay would dictate more light on the ends and less in

the middle. A shorter delay would have the opposite effect.

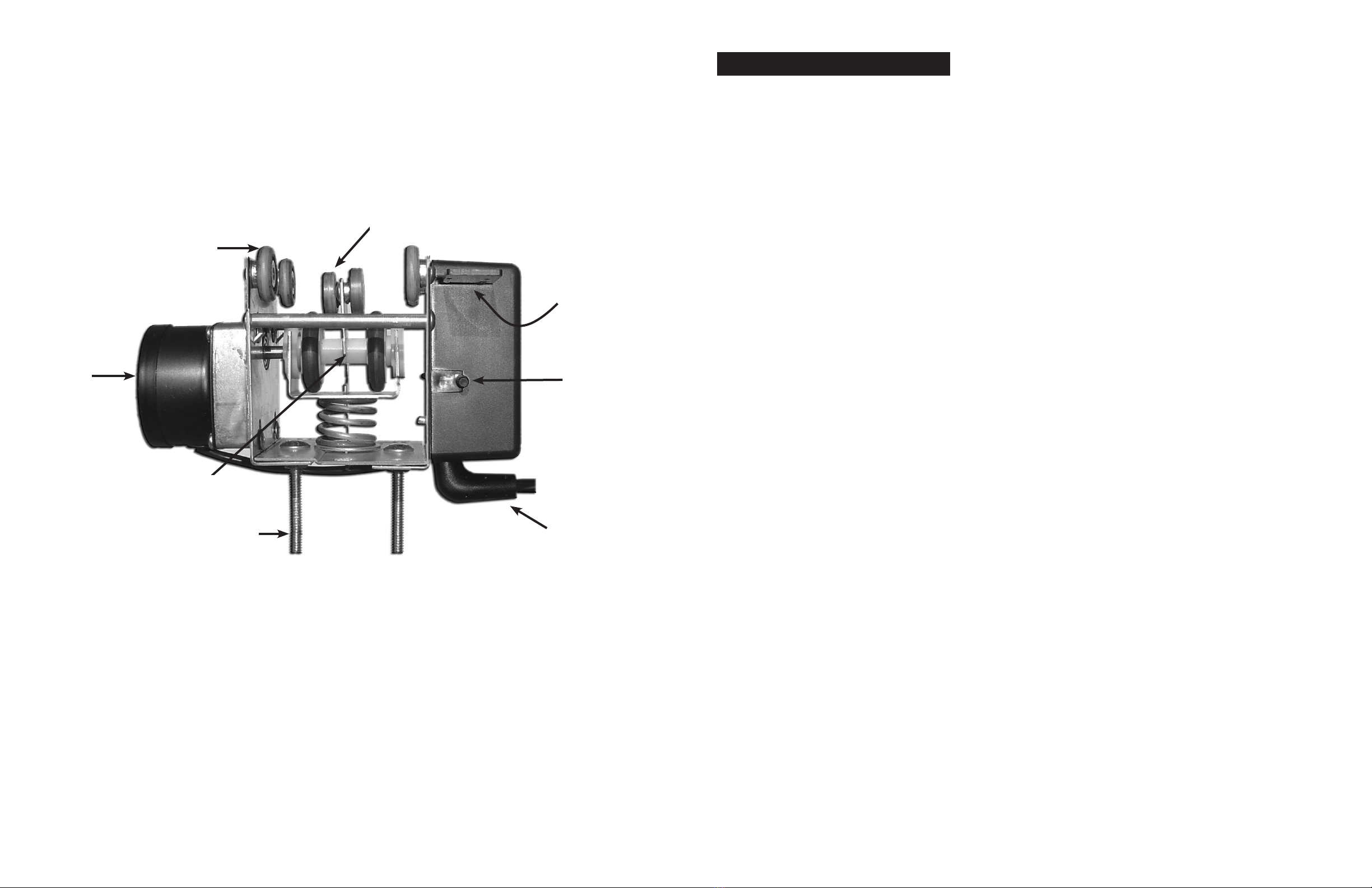

The first few weeks of operation will be the Drive Motor’s break-in period. The Trolley Wheels will turn gray as well as shed some nylon. The Drive Wheel’s

O-Ring may turn silver, and it too will shed some skin. These are both normal conditions as the moving parts of the Drive Motor conform to their respective

grooves of the Rail.

After several weeks of operation you may notice a slight pause as the Drive Motor starts up after changing direction, this is normal. It is the D Hole of the

molded Drive Wheel showing some wear and loosening up upon the Drive Motor’s shaft. Again this is normal and is a good thing as it will allow the Drive

Wheel to self adjust upon the Motor’s shaft. As for the pause when the Drive Motor changes direction, this also is normal and beneficial. It will reduce the

load on the gear train while changing direction.

It is a good idea to use a timer on the Drive Motor. After all, the lamp need not be moving when the lights are out. This period of off time adds up, and

will greatly reduce wear on the Drive Motor.

You should wipe the Rail off with a dry cloth from time to time. If cleaning the Rail becomes necessary use rubbing alcohol or window cleaner. Never use

any petroleum or wax based substance on the Rail or the rubber Drive Wheel.

If Drive Wheel slippage should ever become an issue, it is OK to clean the Drive Wheel’s rubber tires. Again use rubbing alcohol or window cleaner. Never

use any petroleum or wax based substance on the Rail or the rubber Drive Wheel.

LIGHTRAIL *5.0 LIMITED LIFETIME WARRANTY

A. Gualala Robotics Inc. warrants this LightRail 5.0 Drive Motor to be free from defects in materials and workmanship for its usable lifetime. Gualala

Robotics Inc. will repair or replace such product or part thereof which, upon inspection by Gualala Robotics Inc., is found to be defective in materials or

workmanship. This lifetime warranty is limited to non serviceable items only and does not include drive and trolley wheels. As a condition to the obligation

of Gualala Robotics Inc. to repair or replace such product, the product must be returned to Gualala Robotics Inc. together with proof-of-purchase satisfac-

tory to Gualala Robotics Inc.. This warranty is non-transferable.

B. The proper Return Authorization Number must be obtained from Gualala Robotics Inc. in advance of return. Call Gualala Robotics Inc. at 970-761-2596 to

receive the Return Authorization Number to be displayed on the outside of your shipping container.

You must send your dated sales receipt along with a written statement setting forth the name, address, and daytime telephone number of the owner,

together with a brief description of any claimed defects and the drive unit to Gualala Robotics, Inc., 5158 Parfet Street, Unit 3 Wheat Ridge, CO 80033. You

must pay shipping to the factory. After repair or replacement of your drive unit, Gualala Robotics will ship it back at no charge. Parts or product for which

replacement is made shall become the property of Gualala Robotics Inc..

Gualala Robotics Inc. shall use reasonable efforts to repair or replace any LightRail 5.0 Drive Motor covered by this limited warranty within fifteen days of

receipt. In the event repair or replacement shall require more than fifteen days, Gualala Robotics Inc. shall notify the customer accordingly. Gualala Robotics

Inc. reserves the right to replace any product which has been discontinued from its product line with a new product of comparable value and function.

This warranty shall be void and of no force of effect in the event a covered product has been modified in design or function, or subjected to abuse, misuse,

mishandling or unauthorized repair. Further, product malfunction or deterioration due to normal wear is not covered by this warranty.

GUALALA ROBOTICS INC. DISCLAIMS ANY WARRANTIES, EXPRESS OR IMPLIED, WHETHER OF MERCHANTABILITY OF FITNESS FOR A PARTICULAR USE,

EXCEPT AS EXPRESSLY SET FORTH HEREIN. THE SOLE OBLIGATION OF GUALALA ROBOTICS INC. UNDER THIS LIMITED WARRANTY SHALL BE TO REPAIR

OR REPLACE THE COVERED PRODUCT, IN ACCORDANCE WITH THE TERMS SET FORTH HEREIN. GUALALA ROBOTICS INC. EXPRESSLY DISCLAIMS ANY LOST

PROFITS, GENERAL, SPECIAL, INDIRECT OR CONSEQUENTIAL DAMAGES WHICH MAY RESULT FROM BREACH OF ANY WARRANTY, OR ARISING OUT OF THE

USE OR INABILITY TO USE ANY GUALALA ROBOTICS INC. PRODUCT. ANY WARRANTIES WHICH ARE IMPLIED AND WHICH CANNOT BE DISCLAIMED SHALL

BE LIMITED IN DURATION TO A TERM OF ONE YEAR FROM THE DATE OF ORIGINAL RETAIL PURCHASE.

Some states do not allow the exclusion or limitation of incidental or consequential damages or limitation on how long an implied warranty lasts, so the

above limitations and exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state. Gualala Robotics Inc. reserves the right to modify or discontinue, without prior notice to you, any model or style LightRail 5.0 Drive Motor.

If warranty problems arise, or if you need assistance in using your LightRail 5.0 Drive Motor contact:

Gualala Robotics Inc. Tel: 970-761-2596

5158 Parfet Street, Unit 3 Fax: 970-879-6660

Wheat Ridge, CO 80033

NOTE: This warranty is valid to U.S.A. and Canadian customers who have purchased this product from an authorized Gualala Robotics Inc. dealer in the

U.S.A. or Canada. Warranty outside the U.S.A. and Canada is valid only to customers purchased from a Gualala Robotics Inc. international distributor or

authorized Gualala Robotics Inc. dealer in the specific country and please contact them for any warranty service

*TM PATENTED

REPLACEMENT PARTS

Like all moving mechanical objects, parts wear out. e.g. your new car will need new brakes and tires someday. At some point in time your Drive Motor

will need some parts as well. As not all LightRail *5.0 dealers stock these parts, you may want to order them today, so you will have them on hand when

needed.

Gualala Robotics Inc. offers a trolley wheel replacement for sale direct from the factory. It contains two (2) Inner Drive Trolley Wheels as well as four (4)

Outer Trolley Wheels. This trolley wheel replacement sells for $29.95. If you are interested, simply fill out the form below and send it and a money order

payable to Gualala Robotics. We will fill your order promptly. Sorry, no C.O.D. or checks; credit card orders should visit www.lightRail5.com

Gualala Robotics, Inc. offers refurbish services for non-warrantable drive motors and a range of refurbished motors and part kits at www.lightRail5.com. If

you have an older LightRail 3.0 or 3.5 and it is not working or not working to expected standards. Go to LightRail3.com for details.

REPLACEMENT PARTS ORDER FORM

Please send me ______ LightRail 5.0 Trolley Wheel Replacement @ $29.95 (U.S. dollars) each. Included is my money order payable to Gualala Robotics.

NAME

ADDRESS

CITY STATE ZIP

IMPORTANT SAFETY INSTRUCTIONS

Manufactured by Gualala Robotics, Inc., PO Box 774288 Steamboat Springs, CO 80477 USA. *FOR USE WITH GROW LAMPS THAT

ARE U.L. LISTED AND / OR C.S.A. CERTIFIED.* RISK OF FIRE AND ELECTRICAL SHOCK, THIS PRODUCT REQUIRES PROPER FIELD

WIRING AND IS INTENDED TO BE INSTALLED BY A QUALIFIED ELECTRICIAN ONLY. A SURGE PROTECTOR SHOULD BE INSTALLED.

Please read these instructions and the operating instructions before installing your unit. The instructions supplied with your

unit contain important information. Review all documentation before installing your unit.

1. Dropping this unit will cause serious damage to it.

2. Straight and secure Rail mounting is essential for both safety and operation. Refer to STEP TWO of the

mounting instructions inside.

3. If you are using chain and/or hooks to hang your grow light from the drive unit, be sure they are load rated to handle

the weight of your grow light.

4. This unit is rated for use on specific voltage identified by a label fastened to your unit. Never use this unit on a different

voltage than specified.

5. Your unit is equipped with a 3-wire grounding-type electrical plug. This unit will only fit into a grounding-type outlet

and is a safety feature. DO NOT DEFEAT THE GROUNDING CONNECTION. If you are unable to insert the plug into an

outlet, call an electrician to replace the obsolete electrical outlet.

6. After installation, be sure there is plenty of slack in power cords as described in STEP FIVE of instructions.

7. The electrical portion of this unit is non-serviceable. Do not attempt to remove the switch box cover under any circum-

stances. If unit fails to operate due to an electrical malfunction, unplug, remove from Rail and return to manufacturer.

8. Always unplug unit if: you are adjusting grow light height; removing Drive Unit for service; or any procedure. A moving

grow light warrants danger.

9. WARNING: Never wire/hook this unit to your lamps/lights ballast, it will cause damage to the motors circuitry.

www.LightRail5.com

LR5