12

replace it with the plug with bleeding function that

is included in the delivery. The pump of the

apparatus has closed oil circulation that needs no

maintenance. (Refuelling or exchange of oil is not

necessary).

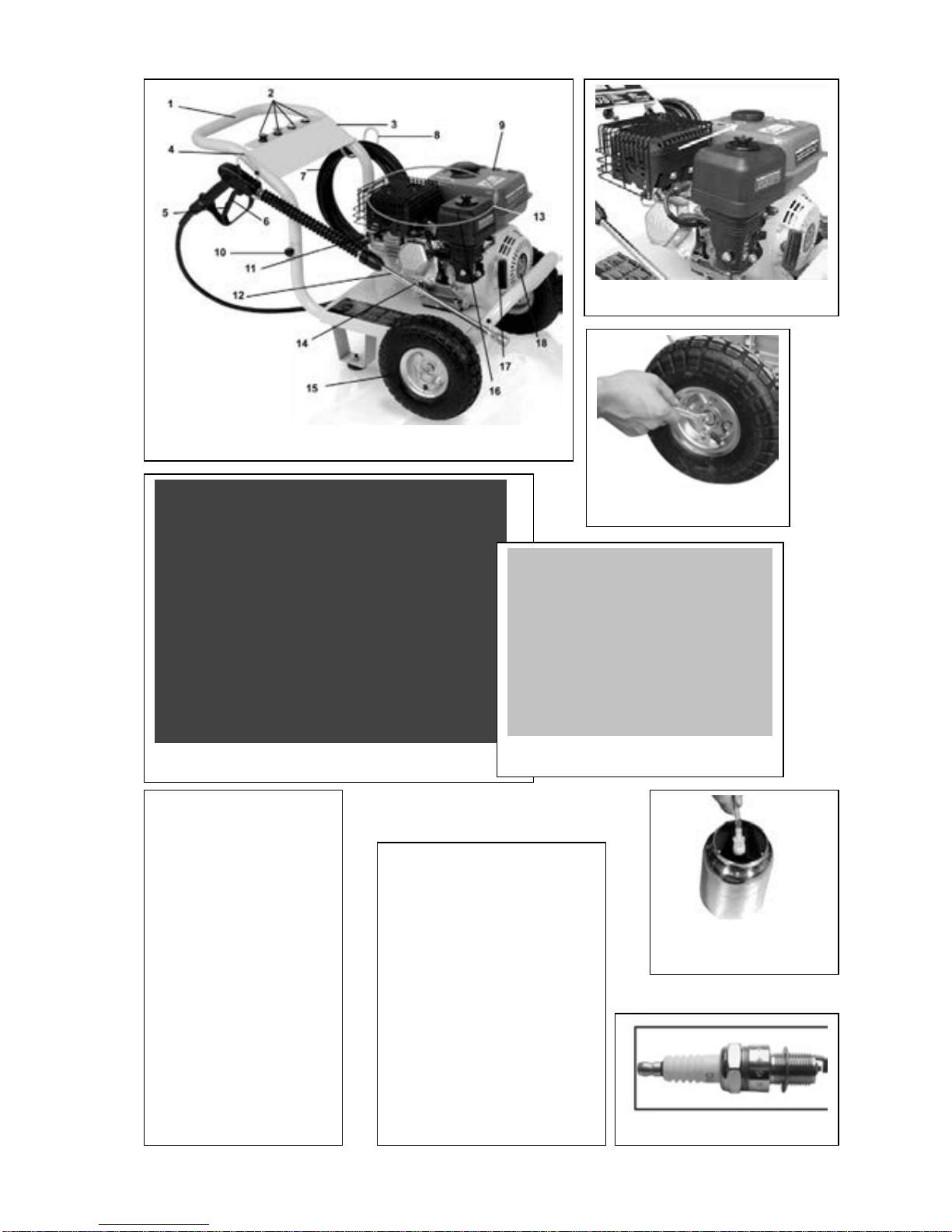

Before Putting into Operation

Following operations shall be performed before

putting the apparatus into operation:

•pour the engine oil into gearbox

•pour the petrol into the tank

•connect the high-pressure hose to the

spray gun and to the pump

•connect the pump to the water main

•connect the jet to the spray gun

Important Warning: The engine and the pump

of your apparatus needs some period of time

to run in. Therefore the apparatus will operate

with full output after a few hours of operation.

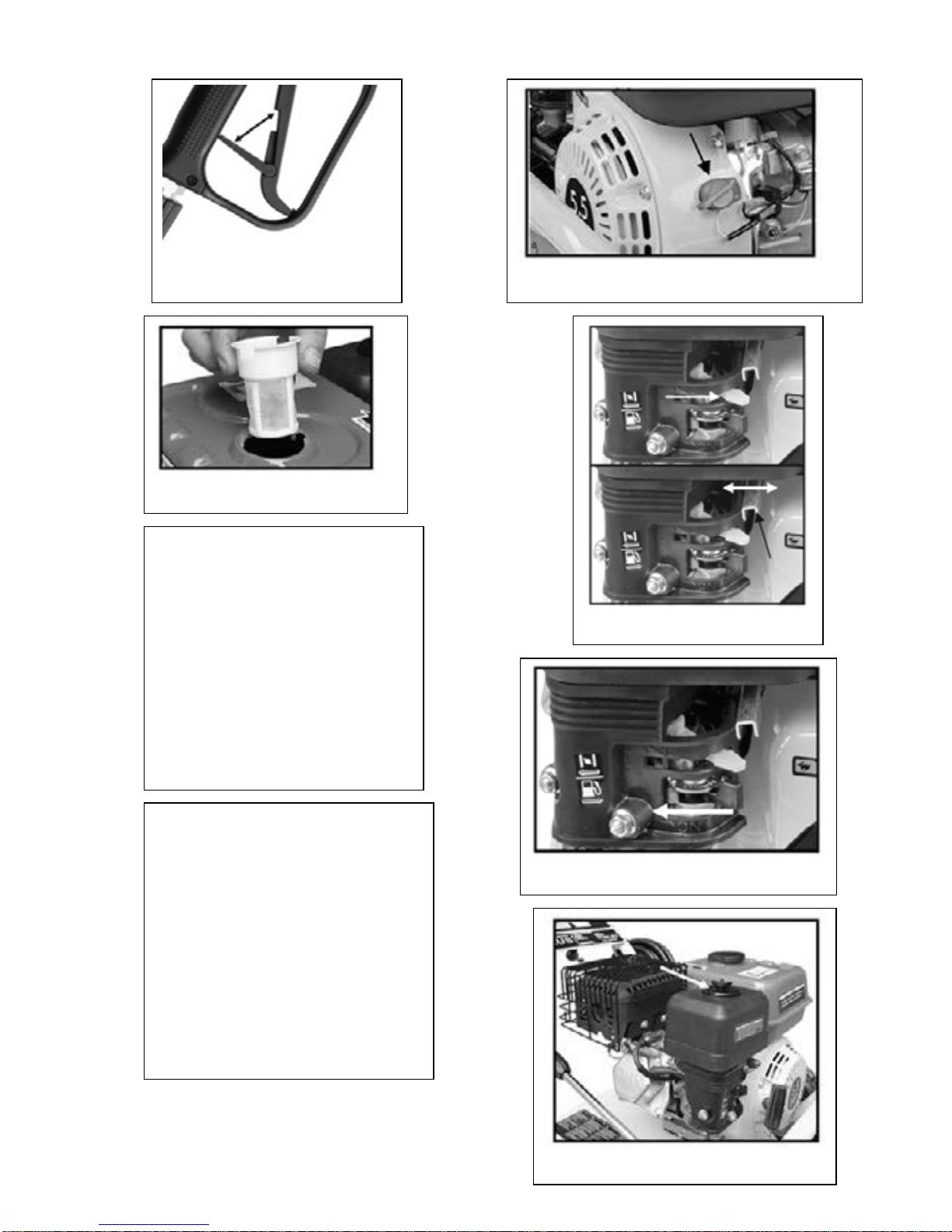

Pouring the Engine Oil into Gearbox (Fig. 12)

Never try to start the apparatus if there is not

enough corresponding oil in the engine. There is

no oil in the apparatus at delivery thereof. If the

apparatus operates without (sufficient quantity of)

engine oil, the engine will get damaged. Place

the apparatus on flat surface and remove the

cover from the oil tank. Fill the engine oil at least

up to the half of the measuring bar length.

Pouring the Petrol into the Tank (Fig. 2)

High-pressure cleaner is driven by a 4-stroke

engine requiring leadless petrol. Use suitable

funnel for filling up the petrol. Make sure there is

not too much petrol in the tank and prevent

spraying the petrol out. The oil should reach up to

the fuel filter, not higher.

Connection of High-Pressure Hose to the

Handle of the Gun and the Pump (Fig. 7)

Put the water pipe on the spray gun. Hold the

end of the gun and screw the pipe on it so that

the connection is firm and sure. Caution! Do not

tighten the screw too much, both supply

connections may be damaged.

The supply connection of the high-pressure hose

with the supply connection on the bottom side of

the spray gun handle connect firmly and safely.

Caution! Do not tighten the screw too much, both

supply connections may be damaged.

Safety Stop for High-Pressure Water Pipe

(Fig. 16)

The gun handle has a safety device preventing

unwanted activation of high-pressure pipe. This

device can be put into operation by leasing the

handle and activating safety stop between the

trigger and the handle.

Connection of the Hose (Fig. 13)

The water supply connection is furnished with

particle filter. Never let the apparatus work

without filter. The intervals for checking and

cleaning of the filters depend on the water

quality. If the water in the water mains contains

impurity articles, the filter shall be cleaned after

every use because otherwise the apparatus

output will (considerably) fall and the pump may

be damaged.

The supply connection part for water supply has

a form of a (male) plug and shall be fastened with

screw on the inlet to water tank of the apparatus.

Put the clamping element (female) to the hose

and then connect this element with the part of

supply connection in form of a plug. Connect the

high-pressure hose to the connection/discharge

for high-pressure. Release water and press the

handle in form of a gun till the water starts flowing

from the pipe continuously. The water

temperature shall not exceed 40 0 C..

Setting the Spraying Angle (Fig. 11)

Warning: The protection against spraying away

shall always be properly set, otherwise it could be

pushed in under the influence of the high-

pressure jet, and it may also cause injury and

damage.

You may chose from 4 different jets market by

your colour that may show various spraying

angles.

0° jet (red):

This jet creates an extremely focused jet with

very high pressure force. It is suitable for

particularly careful cleaning of small areas. The

jet is therefore applicable only on the areas that

can resist such a pressure, e.g. metal or

concrete. Not suitable for wood.

15° jet (yellow):

This jet creates a jet 15° wide, therefore it is

especially suitable for intensive cleaning of

smaller areas. The jet can be used only for areas

that can resist such high pressure.

40° jet (white):

The jet creates a jet 40° wide, water pressure is

medium strong. This jet is suitable for cleaning

larger areas and may be used for most cleaning

works.

Low-Pressure Jet (black):

This jet can be used for chemicals and cleaning

agent’s application. It creates the lowest

pressure.

Important warning: The high-pressure jet can

damage the lining, coating and pavement due

to the type of m aterial or insufficient know-

how. Therefore check first the effect on a

smaller area. If nece ssary the water pressure

can be ch anged by replacement of the jet or

by reduction of the engine output.