8

© Guldmann 04/2021 # 900653_101.1

© Guldmann 04/2021 # 900653_101.1

• Look for cuts or frayed fabric

• Look for unusual or signicant discoloration

• Look for snags, punctures, tears, holes

• Look for frayed or insecure seams

• Look for any acid / caustic / thermal burns

• Look for changes in material consistency, e.g. increased

stiness

• Look for any imbedded particles

Has the shape of the sling been altered, made shorter or

longer in relation to the original size using knots, needles,

tape or other methods?

Conclusion

If the sling suers from one or more of the above mentioned

conditions then it must be taken out of service regardless of the

weight of the person to be lifted.

2.03 Disposal of slings

Slings are disposed of by incineration. By proper incineration

polyester will be degraded to carbon dioxide and water.

3.00 Service and lifetime

3.01 Safety/service inspections

In accordance with international standard EN/ISO 10535 “Hoist for

the transfer of disabled persons – Requirements and test meth-

ods” an inspection must be performed every 6-month according

to the following instructions, which is not intended to represent all

potential inspection steps. Potential damage may vary. Judgment

of inspector/site prevails.

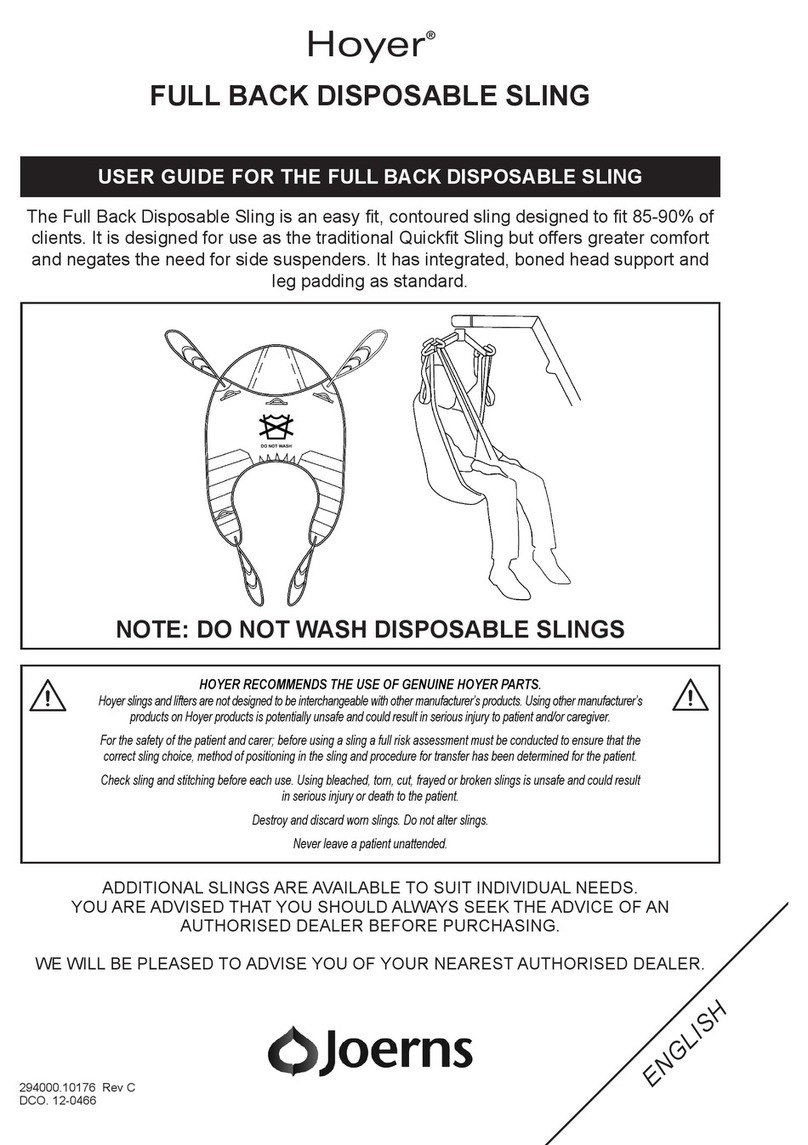

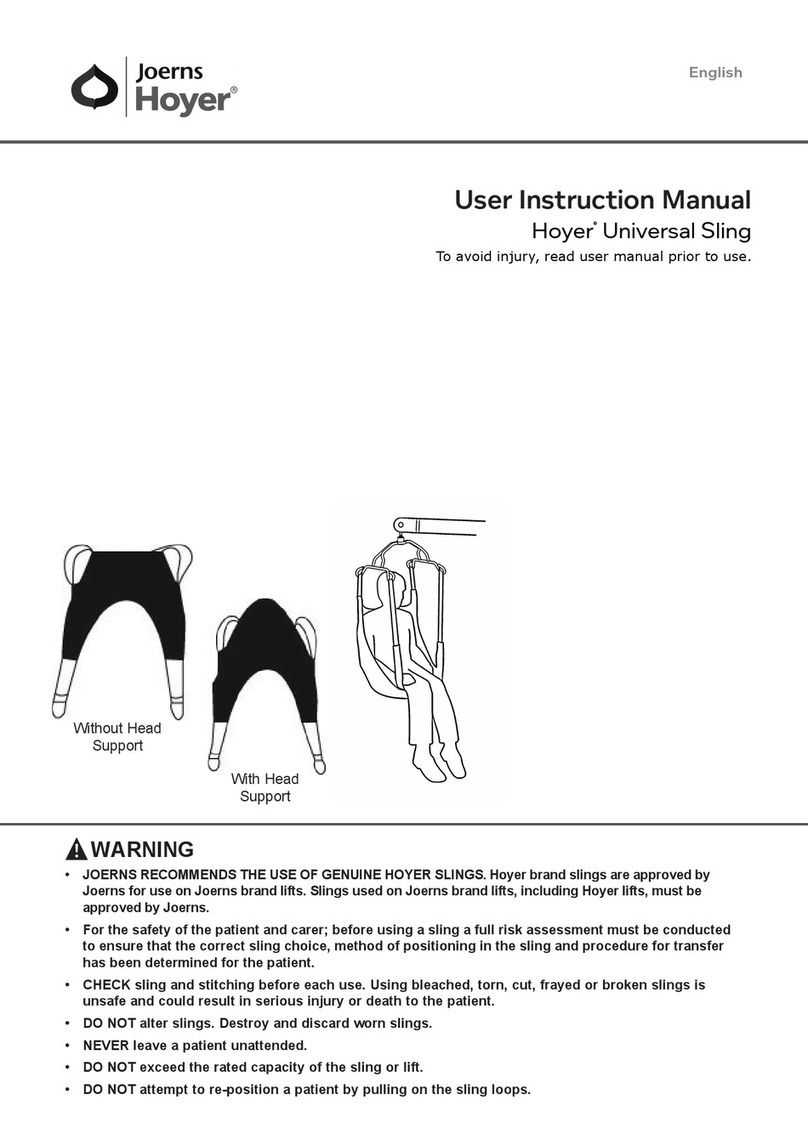

Safe Operating Practices with Slings

Considerations for damaged or defective slings and taking them

out of service:

Withdraw the sling from service if one or more of the following

conditions are present:

• chemical or caustic burns

• melting or charring of any part of the sling

• snags, punctures, tears or cuts

• broken or worn stitches

• missing, illegible or incomplete sling tag

• knots in any part of the sling

• abrasion

• other visible damage that causes doubt as

to the strength of the sling

Sling inspection is done for the protection of the user, the caregiv-

er, and the overall hospital site safety. A sling inspection system

has additional benet. Systematic sling inspection will assist in the

identication of damage trends, potentially leading to cost eective

suggestions and results. The inspection process can also help to

identify inventory duplicity in certain sling types and sizes.

Sling inspection system

Development of a specic procedure and program for the inspec-

tion of slings at your facility is your best safeguard. Consider em-

ploying a three part system of inspection. Slings that are removed

from service and are not capable of repair should be disposed of

so they are unt for any future use and can not nd a way back

into active inventory.

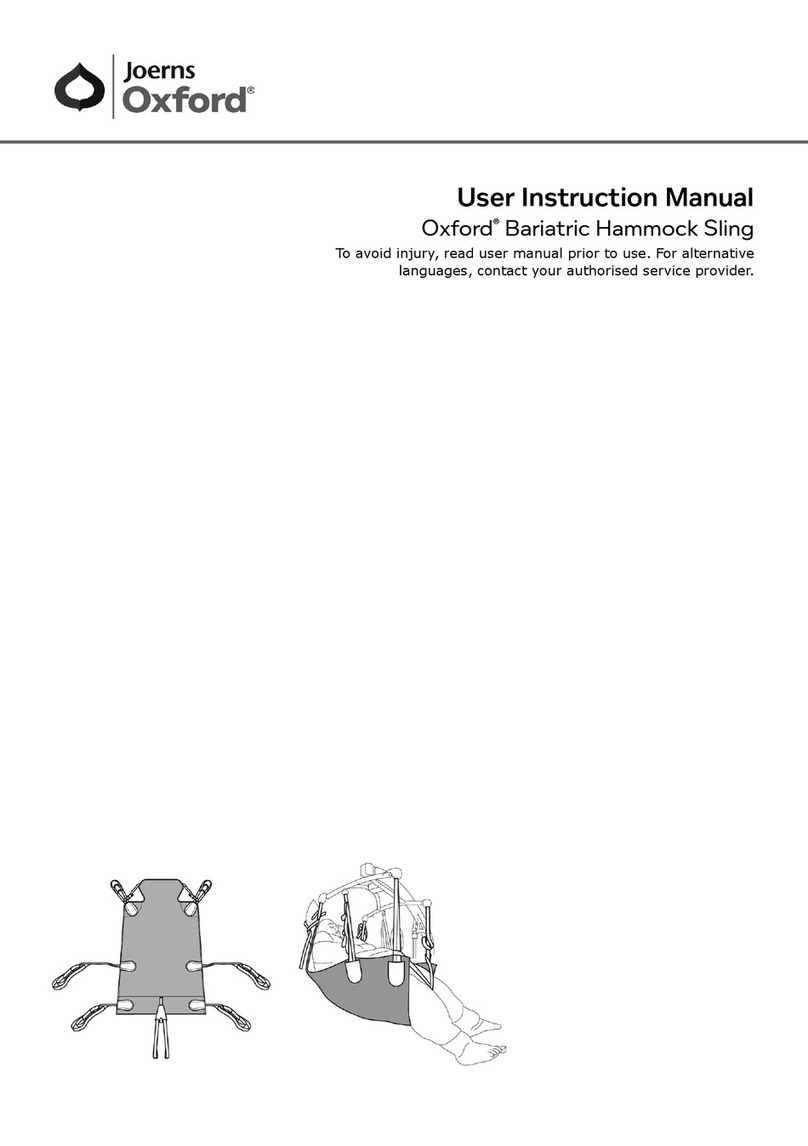

1)Initial

This level of inspection is done at the time that the sling is re-

ceived into your facility. The inspector should ensure that no dam-

age has occurred during transit, and also verify that the sling work

load limits match those contained in the manufacturer’s catalogue.

If your facility documents the sling inspection process through writ-

ten inspection records, the paper trail should begin at this stage.

2)Frequent

The frequent level of inspection should be done by the sling user

before each use. The sling should be examined and removed

from service if damage is detected. The sling user should also

determine that the sling is proper for the user conditions, care task

required and the required weight capacity.

3)Periodic

Your facility might want to consider implementing a program for a

periodic level of inspection at regular intervals. The interval should

be based upon the frequency of use, severity of the service cycle

and information derived through the inspection process. Recom-

mendations to prevent damage and enhance service life could

be made by sta that perform the periodic inspections. If written

inspection records are maintained, they should always reference

the unique sling identication number, and be updated to record

the condition of the sling. Not intended to represent all potential

inspection steps or all potential aspects of product management

program. Judgment of inspector/site prevails.

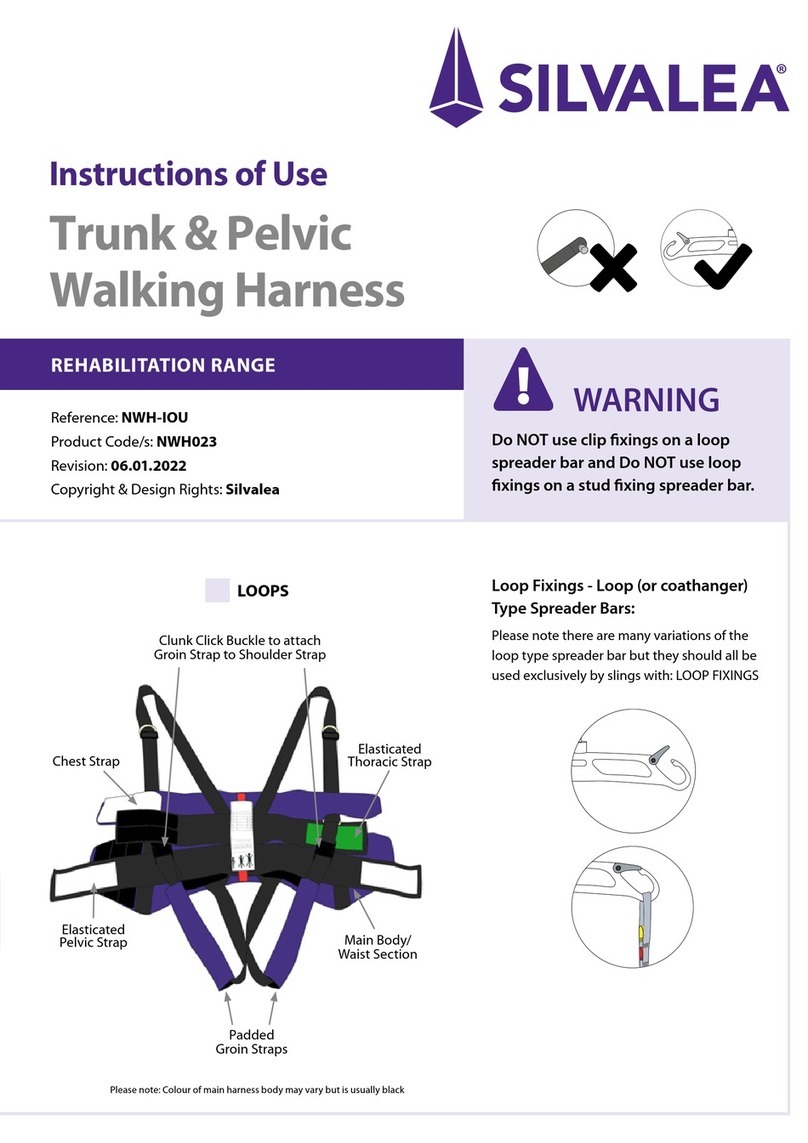

Slinginspectiontechnique

The sling inspection procedure should be thorough, systematic

and consistent; both visual and “hands on” inspection techniques

are recommended. Certain forms of damage are far more discern-

able through hands-on inspection, than by visual inspection. For

example, fabric stiness, crushed webbing, as well as, thinning

fabric can be identied through tactile inspection. Visual inspec-

tion alone may not reveal all forms of sling damage. Once signs

of damage have been identied, do not downgrade the work

load limit of the sling, with the intent of continuing to use it, but at

limited capacity or frequency. This is sometimes done to get more

service life out of a damaged sling. The operating rule and stand-

ard should be: intact = use; damage = do not use.

Consider the practice of documenting sling inspections through

written inspection records. The documentation should include

information such as: the name of manufacturer, the sling stock

number, width and length, the unique sling identication number

(important in dierentiating similar slings), as well as the condition

of the sling. Other important information might also include the

date it was received or put into use at your facility and any special

features (if applicable). A benecial outcome of an inspection pro-

gram would be the realization of repetitive forms of damage and

the analysis that would lead to specic recommendations.

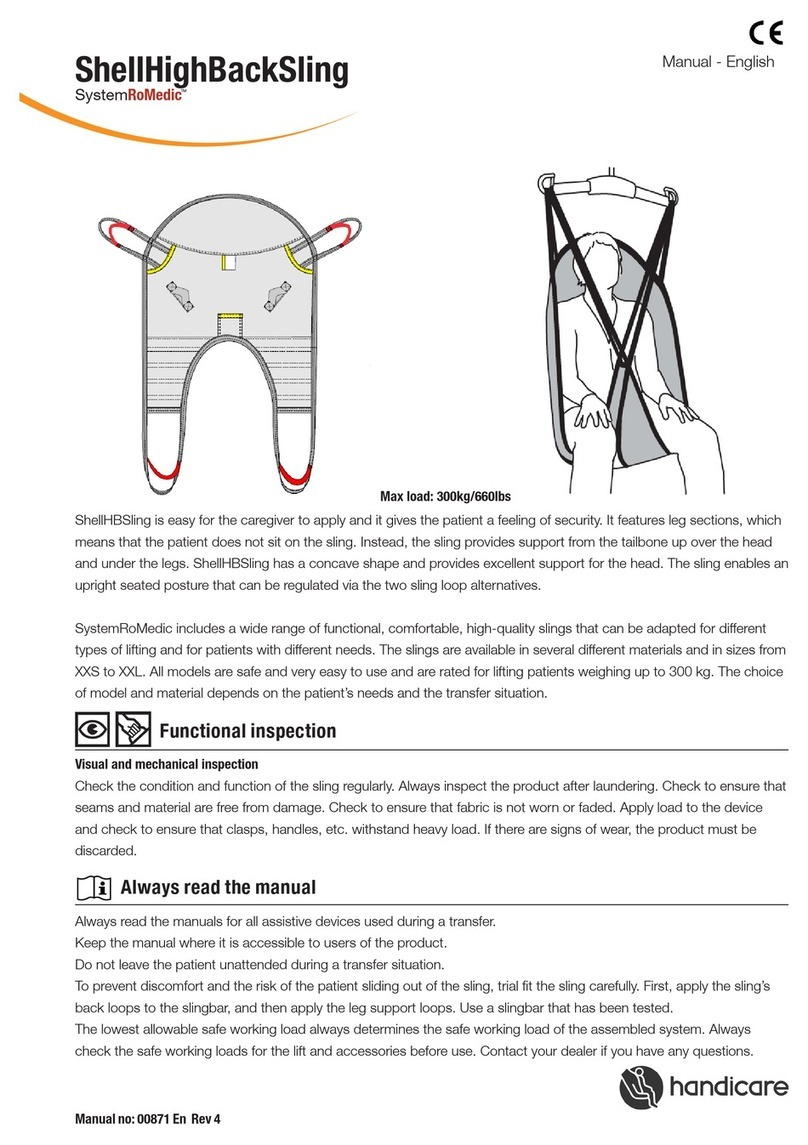

Sample visual examples of synthetic sling damage x)

Chemical/caustic burns

Broken stitching

Crushed / Frayed webbing

Knots