3

M00000118- E-uk – 06.07 DL645 and Simplex 45

Anti Reversal Device..........................................................................23

Positioning Sensors............................................................................23

Sensor Actuators................................................................................23

Sensors...............................................................................................24

Tripod..................................................................................................24

Static Hub Version..............................................................................24

Emergency Drop Arm Device (Optional)............................................25

Electrical Schematics .........................................................................26

LL2001 Control Logic Board...............................................................29

LL2001 Board Inputs..........................................................................30

LL2001 Board Outputs .......................................................................31

LL2001 Board Connectors .................................................................32

Power supply unit...............................................................................34

SECTION 5 Installation

Unpacking...........................................................................................35

Tools required.....................................................................................35

Site Preparation..................................................................................35

Environmental conditions ...................................................................35

Power Supply Characteristics ............................................................36

General Conditions.............................................................................36

Cabling................................................................................................37

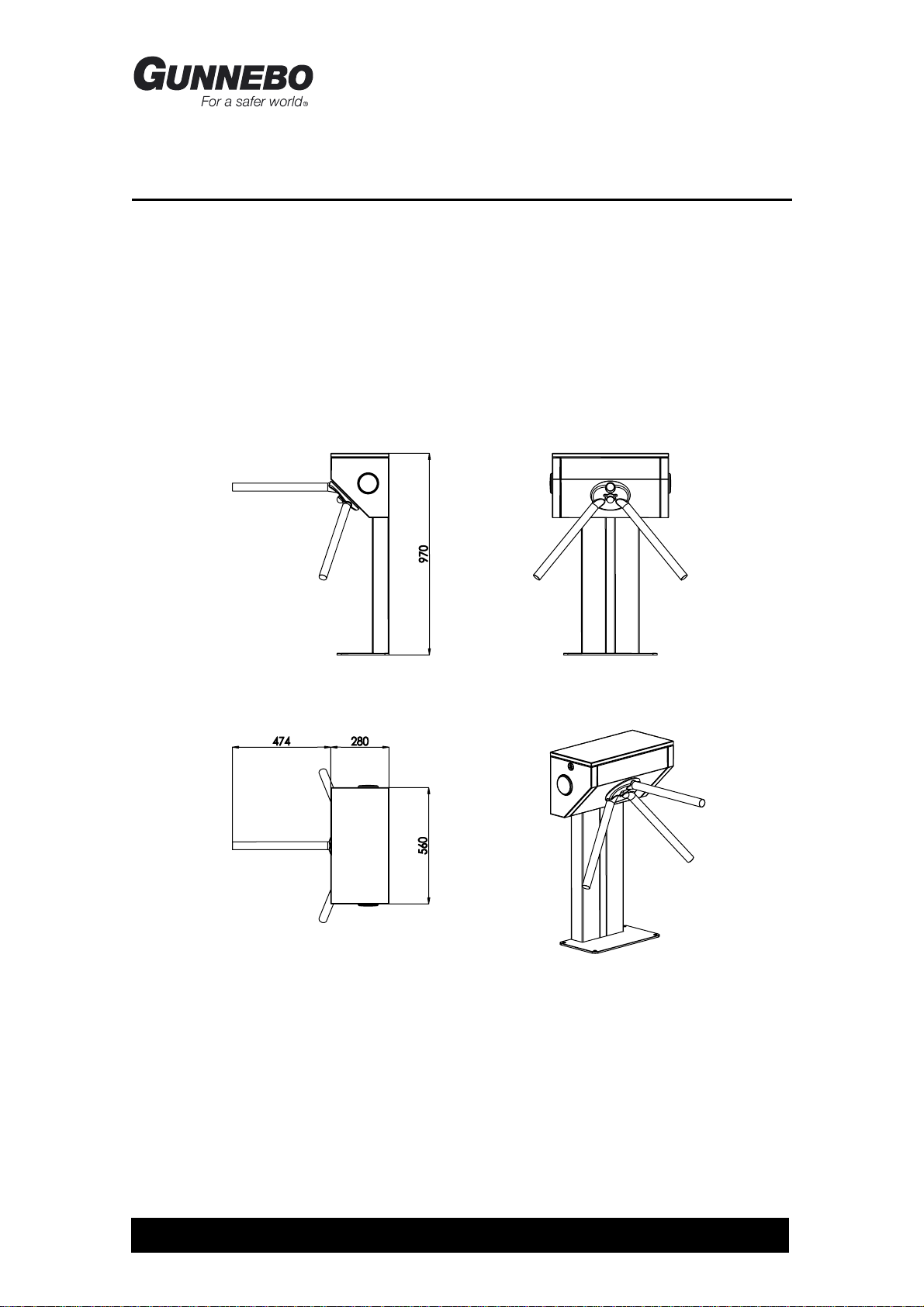

Mounting Details.................................................................................38

Unit Positioning...................................................................................41

Electrical Connections........................................................................42

Power Supply .....................................................................................42

Connection with readers.....................................................................43

MP2000 Remote Control Unit connection..........................................43

Emergency / Fire Alarm......................................................................44

RS485 Serial Line...............................................................................44

SECTION 6 Maintenance

General Care......................................................................................45

Routine Maintenance..........................................................................46

Monthly Checks..................................................................................46

Annual Checks ...................................................................................46

Trouble-Shooting................................................................................48

Fault Finding.......................................................................................49

LL2001 Board Replacement...............................................................50

SECTION 7 Spare Parts........................................................................................51

SECTION 8 Table Appendices

Table 8.1 Trimmer TR1 (Solenoids configuration).............................54

Table 8.2 Trimmer TR2 (Reader management).................................54

Table 8.3 Trimmer TR3 (Timings)......................................................55

Table 8.4 Trimmer TR4 (Authorizations stacking,

Counting pulse sequence)..................................................................55

Table 8.5 Trimmer TR5 (REL2, REL3, Traffic Lights)........................56