H.E. Anderson Ratio Feeder DB Series Owner's manual

Ratio Feeder®

DB & DD Series Injectors

GETTING TECHNICAL ASSISTANCE

The H.E. Anderson Company is dedicated to assisting our customers with installation and use o our

products. Our technical sta are available each weekday rom 8:30am to 4:30pm central time. You may

call us toll ree at 1-800-331-9620 rom anywhere in the U.S.A. and Canada. I no one is available, we will

promptly return your call.

Before you call we suggest that you review this manual. You may ind the answer to your question here.

But even i you do not, reviewing the manual will help us to help you.

There is some information you should have available when you call. You should know the model and

serial number o your control unit. Also, you should note the number o pumpers o each type, and their

model numbers ( ound under the adjustment knob, stamped into the casting). We may not need all this

in ormation, but having it available at the start can sometimes save a lot o time and trouble or you.

I you need an additional owners manual or any H.E. Anderson Company product, please visit our

website at http://heanderson.com/manuals.php

Record the in ormation rom your control panel below: (See Photo, Page 4)

Model # ________ Serial # ________ Feed Ratio 1:______ Internal Switch Settings ____________

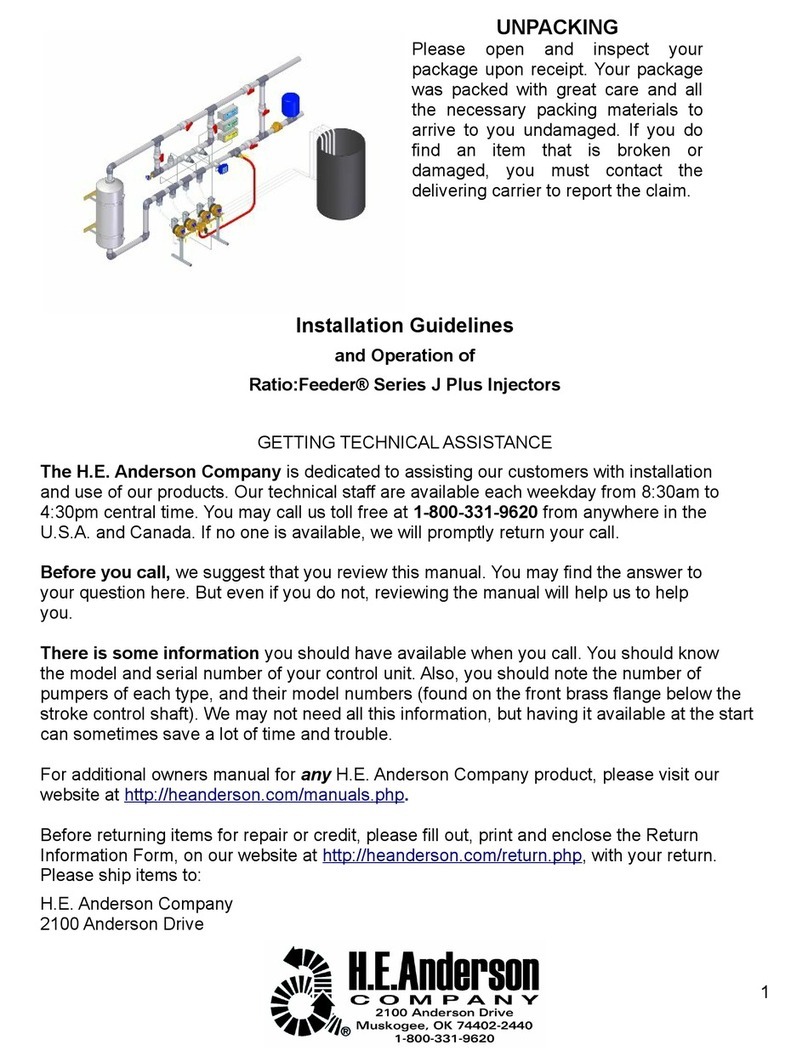

UNPACKING

Please open and inspect

your package upon receipt.

Your package was packed

with great care and all the

necessary packing materials

to arrive to you undamaged.

I you do ind an item that is

broken or damaged, you

must contact the delivering

carrier to report the claim.

Model DD100 Injector

DD & BB Series

DD/DB 04/2015 2H.E. Anderson Company

DD & BB Series

This manual covers the DD and DB Series

injectors. We will re er to them simply as

“injector” in this manual. Parts breakdowns are

in the rear o this manual.

you should have received the ollowing with your

unit.

●DD/DB Injector(assembled).

●Check Valves & Injection Fitting.

●Foot Valve or Priming Stick.

●8' Piece o Clear Tubing,1/2"

or

13' Piece o Black Tubing,3/8".

●5' Piece o Red Hose,3/4".

●This Owners Manual.

●Pumper Manual or the pumper

supplied with your unit.

●Pumper Calibration Manual.

I there are missing parts, please call your

distributor.

Installation

Double check the direction of

water flow when you install your

injector.

The model DD has 1-1/4" NPT pipe connections.

The model DB has 1" NPT pipe connections.

You can adapt to other pipe sizes i needed We

recommend that the injector be installed in a

bypass to allow you to service it i the need

arises.

The check valve(s) have a yellow

arrow stamped on them. These

arrows must point up when

installed.

Re er to the the typical installation drawing

(Page 4) and parts breakdown or your model

or proper installation o chemical check valves

and tubing.

●Install the valve module or chemical

check valves on the plastic pumphead.

●The oot valve or priming stick goes into

the chemical tank.

●Connect a length o plastic tubing rom

the chemical tank to the lower hose barb

or the lower check valve.

●Connect a short piece o tubing rom the

discharge valve or upper hose barb to

the injection point itting (IPF).

●C o n n e c t t h e 3 / 4 " r e d h o s e t o

t h e hose barb on the bottom o the pilot

valve. There will be waste water emitted

rom this hose during the pumping cycle.

The volume discharged will be

approximately three times that o

chemical pumped. The wa t e r th a t i s

em i tte d i s c l ea r, untreated water.

This hose must vent to atmosphere

and cannot be elevated or restricted.

Initial System Check

Use a power surge protector to

help prevent electrical surges

from damaging the unit. Power

surges lightning and other

“acts of God” are not covered under the

warranty.

The injector uses 12VDC power

to operate. Do not run 120VAC

directly into the unit. Always

use the supplied transformer

when possible. Once you have applied

power we are ready for the initial system

check.

●Apply power to your injector.

●Watch the lighted indicators located in

the cover.

●The power light(red) should be on

constantly.

●The low light(yellow) should lash when

there is water lowing.

●The cycle light(green) lashes when the

injector makes a pumping cycle

(depending on the volume o water low,

it may take several seconds or this light

to lash).

●I the lights are not operating correctly,

immediately unplug the unit and call

your distributor or H.E. Anderson Co. to

report the problem.

DD/DB 04/2015 3H.E. Anderson Company

DD & BB Series

Optional Flow Totalizer

The low totalizer (optional) is a resettable

counter or accumulating the water low and is

equipped with a 10 year battery to retain

memory. The meter will accumulate low even i

injection is turned o .

The PRIME ON/OFF Switch

This button (see photo above) allows you to turn

o the injection o chemical, but still record the

low i you have the optional counter/totalizer.

●To turn the injection OFF, press

the button. Injection will stop.

●To turn the injection ON, press the

button. The valve light will lash and the

injector will make the irst pumping

stroke.

●When priming the injector, you can

make repetitive pumping strokes by

pressing the PRIME ON/OFF switch

OFF and ON. Be sure to leave the unit

on a ter priming.

NOTE: Priming is quicker and easier at a dial

setting of 10.

You must have at least 30 psi of

back pressure in order for the

system to operate correctly.

Setting the Pumper

At a dial setting o 10, the eed ratio will be that

shown on the control panel. (See Photo 1.) That

is the maximum eed or your unit. I you wish to

eed less, the eed dial may be set to a lower

setting.

Example: I your injector chemical:water eed

ratio at 10 is 1:200, at a setting o 5 it will eed

hal as much, which corresponds to a

chemical:water eed ratio o 1:400.

Once your injector is set, it is ully operational.

Maintenance & Storage

Servicing the Pumper

Your injector normally requires very little

maintenance.

For servicing and calibrating your pumper and

chemical valves, re er to the separate pumper

and pumper calibration manuals supplied with

your unit. For pilot valve problems re er to the

separate pilot valve manual. I you are unable to

locate them, they are all available on our

website at http://heanderson.com/manuals.php.

Storage

Warning! Your injector can be

damaged if allowed to freeze.

Freeze damage is not covered

under warranty.

You should take the necessary precautions to

protect the injector rom reezing.

●I you remove your injector rom the line

or the winter, you should drain the

water rom it.

●You should also remove the pumper

rom the pilot valve and drain the water

rom it.

DD/DB 04/2015 4H.E. Anderson Company

Internal

Switch

Settings

Feed Ratio

at 10 on Dial

Model # Serial #

DB/DG Control Panel

DD & BB Series

DD/DB 04/2015 5H.E. Anderson Company

DD & BB Series

DD/DB 04/2015 6H.E. Anderson Company

DD & BB Series

DD/DB 04/2015 7H.E. Anderson Company

DD & BB Series

DD/DB 04/2015 8H.E. Anderson Company

DD & BB Series

DD/DB 04/2015 9H.E. Anderson Company

10 1

11

12

2

3

4

3

2

5

6

7

8

9

13

14

15

16

17

DD & BB Series

DD/DB 04/2015 10 H.E. Anderson Company

1

10

4

11

12

2

3

3

2

5

6

7

8

9

13

14

15

16

17

H.E. Anderson Company DD/DB Power & Quick Facts 03/03/08

POWER CONSUMPTION FOR DSERIES (ANDY AND ANDY JR)

MODEL CURRENT WATTAGE

DB100, 1000 338mA 4.06 W

DB200, 400 234mA 2.81 W

DB1200 95mA 1.07 W

DD100, 200, 400, 1000 338mA 4.06 W

DD1200 200mA 2.40 W

Power consumption is an average. Ratings based on a maximum flow rate of unit @ 12.4VDC.

QUICK FACTS FOR DSERIES (ANDY AND ANDY JR)

Andy (DD) models, ¾ to 50 GPM water flows.

Model Max Min Pumper Gallons ml/ strokes/min

Ratio Ratio Size per Stroke Stroke at max flow

DD100 1:100 1:1000 H4-HD 1.06 40 47.3

DD200 1:200 1:2000 H2-HD 1.06 20 47.3

DD400 1:400 1:4000 A10-VCP 1.06 10 47.3

DD1000 1:1000 1:10000 A3-VCP 0.79 3 63.1

DD1200 1:1200 1:12000 P1-BA 3.17 10 15.8

Andy Jr (DB) models, ¼ to 20 GPM water flows.

Model Max Min Pumper Gallons ml/ strokes/min

Ratio Ratio Size per Stroke Stroke at max flow

DB100 1:100 1:1000 P2-HC 0.53 20 37.7

DB200 1:200 1:2000 P1-HC 0.53 10 37.7

DB400 1:400 1:4000 A10-VCP 1.06 10 18.9

DB1000 1:1000 1:10000 A3-VCP 0.79 3 25.3

DB1200 1:1200 1:12000 P1-BA 3.17 10 6.3

RATIO:FEEDER® LIMITED WARRANTY

WHAT IS COVERED

The H.E. Anderson Company of M skogee, Oklahoma, will make any necessary repairs

and/or replace any parts of any Ratio:Feeder® prod ct made necessary beca se of defects in

materials or workmanship for fifteen months from date of man fact re. Warranty repairs

and/or replacements will be performed witho t charge to the owner by H.E. Anderson

Company within a reasonable time after prepaid delivery of the defective prod ct to the H.E.

Anderson Company, 2100 Anderson Drive, M skogee, Oklahoma 74403.

WHAT IS NOT COVERED

This warranty specifically excl des fail re of any parts or materials ca sed by chemical

attack or damage ca sed by operation above rated capacity or press re. F rther, this warranty

does not cover wear or fail re ca sed by sand or other foreign materials which may be fo nd in

water that is passed thro gh o r prod cts, or damage ca sed by freezing or expos re to water

temperat res above 60 °C (140 °F).

This warranty does not cover damage ca sed by fail re to follow prescribed installation

instr ctions and limitations iss ed by H.E. Anderson Company. In addition, this warranty does not

cover service adj stments, repairs, or replacements ca sed by mis se, negligence, alteration,

accident, or lack of specified maintenance.

This warranty does not cover components sed by, b t not man fact red by H.E. Anderson

Company, in the man fact re of o r prod cts except to the extent of said component

man fact rer's warranty.

This warranty specifically excl des liability for conseq ential damages or for charges for labor or

expense in making repairs or adj stments, or losses of time or inconvenience.

This warranty gives yo specific legal rights and yo may also have other legal rights which

may vary from state to state. H.E. Anderson Company does not a thorize any person to create

for it any other obligation or liability in connection with these prod cts. ANY IMPLIED

WARRANTY APPLICABLE TO THESE PRODUCTS IS LIMITED TO THE DURATION OF THIS

WARRANTY. H.E. Anderson Company shall not be liable for conseq ential damages res lting

from breach of this written warranty.

NOTE: Some states do not allow limitation on how long an implied warranty will last or the

excl sion of limitations of incidental or conseq ential damages, so the above limitations or

excl sions may not apply to yo .

WHAT TO DO IF THERE IS A QUESTION REGARDING WARRANTY

1) Promptly notify the cons mer adviser at H.E. Anderson Company by telephone at 800-331-9620 or

918-687-4426.

2) Confirm the report in writing (or via FAX at 918-682-3342) to the H.E. Anderson Company, stating

the circ mstances s rro nding the problem.

PURCHASER'S OBLIGATION

a) P rchaser m st give H.E. Anderson Company immediate written notice on discovery of

defect.

b) P rchaser m st pay for shipment of the defective prod ct to the H.E. Anderson Company, 2100

Anderson Drive, M skogee, Oklahoma 74403.

RFLW 1/12

This manual suits for next models

12

Table of contents

Other H.E. Anderson Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Philips

Philips UV-C 9290024887 user manual

Thermo Scientific

Thermo Scientific 146i instruction manual

Thermo Scientific

Thermo Scientific Applied Biosystems QuantStudio user guide

Beckman Coulter

Beckman Coulter BioLector XT Safety Notices

De La Rosa Research

De La Rosa Research 31202A user manual

Leica BIOSYSTEMS

Leica BIOSYSTEMS ASP300S Instructions for use